Stainless angle steel; high quality angle steel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless angle steel; high quality angle steelGeneral Informaiton of Stainless angle steel; high quality angle steel

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry etc.

Specification of Stainless Steel Angle Bar

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316 | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

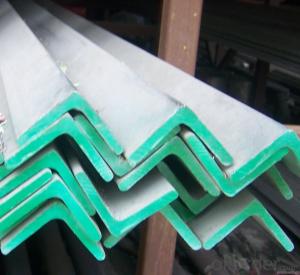

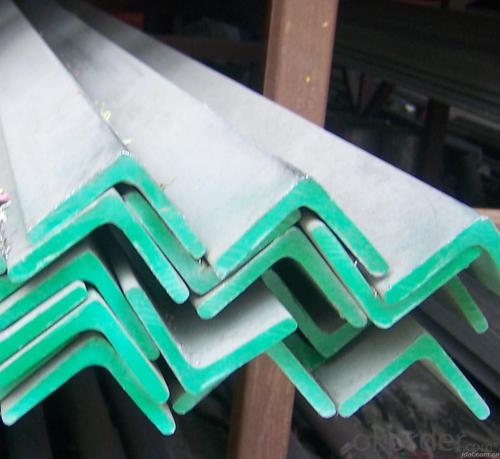

Pictures of Stainless angle steel; high quality angle steel

- Q: What are the standard dimensions for unequal leg steel angles?

- The standard dimensions for unequal leg steel angles can vary depending on the specific requirements of a project or the country in which they are being used. However, there are generally accepted standard dimensions that are commonly used in various industries. In the United States, the standard dimensions for unequal leg steel angles are typically defined by the American Society for Testing and Materials (ASTM). According to ASTM A6/A6M, the standard specification for general requirements for rolled structural steel bars, plates, shapes, and sheet piling, unequal leg steel angles are designated by their nominal size and weight per foot. For example, a commonly used unequal leg steel angle would have a nominal size of 2 x 1-1/2 inches and a weight per foot of 2.71 pounds. Another common size would be 3 x 2 inches with a weight per foot of 4.23 pounds. These dimensions may vary depending on the specific requirements of a project, but they serve as a general guide for the standard dimensions of unequal leg steel angles.

- Q: Can steel angles be used in railway track construction?

- Yes, steel angles can be used in railway track construction. Steel angles are often used as structural components in the construction of railway tracks due to their strength, durability, and ability to provide support and stability to the tracks.

- Q: What is the fire resistance rating of steel angles?

- The fire resistance rating of steel angles varies depending on the specific dimensions and configuration of the angle, as well as the fire protection measures implemented. In general, steel has good fire resistance properties due to its high melting point, but additional fireproofing measures such as fire-resistant coatings or insulation may be necessary to enhance its fire resistance rating. It is important to consult relevant building codes, fire protection standards, and engineering specifications to determine the specific fire resistance rating of steel angles in a given application.

- Q: Can steel angles be used for decorative purposes?

- Yes, steel angles can definitely be used for decorative purposes. Steel angles are versatile and can be shaped and formed into various designs and patterns, making them a popular choice for adding a decorative touch to interior and exterior spaces. They can be used to create decorative accents such as trim, frames, and brackets. Additionally, steel angles can be easily painted or powder-coated in different colors to match any desired aesthetic. The durability and strength of steel angles also ensure that they will withstand the test of time, making them a practical and attractive option for decorative applications.

- Q: Angle iron specifications 125 * 80 * 101 m multiple

- Angle steel is a kind of carbon structural steel for construction. It is a simple section steel, mainly used in the frame of metal component and workshop. In use, better weldability, plastic deformation and mechanical strength are required. The raw steel billet for producing angle steel is low carbon square billet, and the finished product angle iron is made by hot rolling, normalizing or hot rolling.

- Q: What are the different methods of connecting steel angles to other structural elements?

- There are several methods of connecting steel angles to other structural elements, depending on the specific application and load requirements. One common method is through welding. Welding involves melting and fusing the steel angle to the other structural element using intense heat. This creates a strong and durable connection that can withstand high loads. Welding is often used when the connection needs to be permanent and when the load requirements are significant. Another method is through bolting. Bolting involves using bolts and nuts to secure the steel angle to the other structural element. This method allows for easy disassembly and reassembly if needed, making it more flexible than welding. Bolting is often used when the connection needs to be adjustable or when the load requirements are relatively lower. Riveting is another method that can be used to connect steel angles to other structural elements. Riveting involves joining the steel angle and the other element by inserting a metal pin, called a rivet, through aligned holes and then deforming the end of the rivet to secure it in place. This method creates a strong and reliable connection, but it may be more time-consuming and labor-intensive compared to welding or bolting. Additionally, adhesive bonding can also be used to connect steel angles to other structural elements. This method involves using specialized adhesives that can bond the surfaces of the steel angle and the other element together. Adhesive bonding can provide a strong and uniform connection, and it is often used when aesthetics are important or when joining dissimilar materials. In summary, the different methods of connecting steel angles to other structural elements include welding, bolting, riveting, and adhesive bonding. The choice of method depends on factors such as the load requirements, desired flexibility, ease of assembly and disassembly, and the specific application.

- Q: Are steel angles suitable for corrosive environments?

- Corrosive environments can be suitable for steel angles depending on the specific conditions and the type of steel utilized. Stainless steel angles, for instance, exhibit exceptional resistance against corrosion due to their composition rich in chromium and nickel. These angles find extensive application in environments that encounter moisture, chemicals, or saltwater, such as marine applications or industrial settings. On the other hand, carbon steel angles may not be as appropriate for corrosive environments as they tend to be more susceptible to rust and corrosion. In such instances, it may be necessary to employ additional protective measures like coatings or galvanization to enhance their resistance against corrosion. To determine the most suitable steel angles for corrosive environments, it is crucial to consider the specific corrosive elements present in the environment, the extent of exposure, and the desired longevity of the angles. Seeking guidance from a corrosion specialist or an engineer with expertise in materials selection can aid in making informed decisions.

- Q: What are the different load-carrying capacities for steel angles?

- The load-carrying capacities for steel angles can vary depending on several factors such as the size and shape of the angle, the type of steel used, and the specific application or use case. Generally, load-carrying capacities for steel angles are determined by considering the maximum allowable stress or load that the angle can withstand without experiencing permanent deformation or failure. This is often expressed in terms of the maximum axial or bending load that an angle can support. To determine the load-carrying capacity of a specific steel angle, engineers and structural designers refer to industry standards and guidelines, such as the American Institute of Steel Construction (AISC) Manual of Steel Construction. These standards provide tables and formulas that take into account various factors such as the angle's dimensions, thickness, and moment of inertia to calculate its load-carrying capacity. It is important to note that load-carrying capacities for steel angles are typically specified for specific loading conditions and safety factors. These factors include the type of load (e.g., axial or bending), the direction and magnitude of the applied load, and the safety factor required to ensure the structural integrity and durability of the angle. Therefore, it is essential to consult the relevant codes, standards, and engineering resources to determine the specific load-carrying capacity of a particular steel angle for a given application. Professional structural engineers and designers are best equipped to assess and determine the load-carrying capacities of steel angles based on their expertise and familiarity with the applicable design codes and standards.

- Q: Can steel angles be used for storage rack systems?

- Yes, steel angles can be used for storage rack systems. Steel angles provide structural support and stability, making them a suitable choice for constructing storage racks that can hold heavy loads and withstand frequent use. The versatility and strength of steel angles make them a popular choice in various industrial and commercial storage applications.

- Q: How are steel angles protected against abrasion?

- Steel angles can be protected against abrasion through various methods, such as applying anti-abrasion coatings, using rubber or plastic lining, or incorporating sacrificial wear plates. These protective measures help to minimize the wear and tear caused by friction and ensure the longevity and durability of the steel angles.

Send your message to us

Stainless angle steel; high quality angle steel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords