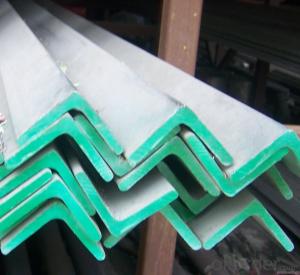

High Quality Stainless angle steel; enqual angle and unequal angle steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offeringHigh Quality Stainless angle steel for Construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High QualityHigh Quality Stainless angle steel for Construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder'sHigh Quality Stainless angle steel for Construction are durable, strong, and resist corrosion. They are newly produeced by good materiales.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of High Quality Stainless angle steel for Construction

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications ofHigh Quality Stainless angle steel for Construction

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery ofHigh Quality Stainless angle steel for Construction

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of High Quality Stainless angle steel for Construction

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel angles be used as supports for suspended acoustical ceilings?

- Yes, steel angles can be used as supports for suspended acoustical ceilings. Steel angles are often used as a main structural component in suspended ceiling systems. They provide stability and support for the acoustical ceiling tiles and help distribute the weight evenly across the ceiling grid. The steel angles are typically installed at regular intervals along the perimeter of the ceiling and are connected to the main suspension system. This ensures that the acoustical ceiling remains securely in place and can effectively absorb sound and improve the overall acoustics of the space.

- Q: Can steel angles be used for supports in construction?

- Yes, steel angles can be used for supports in construction. Steel angles are commonly used in construction projects as structural supports due to their strength and versatility. They can be used in various applications such as supporting beams, columns, and frames. Steel angles provide stability and rigidity to the structure, making them suitable for supporting heavy loads and withstanding forces such as gravity and wind. Additionally, they can be easily welded or bolted together, allowing for quick and efficient installation. Overall, steel angles are a popular choice for construction supports due to their durability, strength, and ease of use.

- Q: How do you prevent rust on steel angles?

- To prevent rust on steel angles, there are several steps you can take: 1. Apply a protective coating: One of the most effective ways to prevent rust is to apply a protective coating on the steel angles. This can be done using paint, varnish, or other corrosion-resistant coatings. Make sure to choose a coating that is specifically designed for preventing rust on steel surfaces. 2. Use galvanized steel angles: Galvanization is a process where a layer of zinc is applied to the steel, providing a protective barrier against rust. Using galvanized steel angles can significantly reduce the risk of rust formation. These angles are readily available in the market and are a popular choice for outdoor applications. 3. Keep moisture away: Rust formation is accelerated by moisture, so it is crucial to keep steel angles dry. Avoid exposing them to rain, humid environments, or excessive moisture. If the angles are installed outdoors, ensure proper drainage and provide adequate ventilation to prevent the buildup of moisture. 4. Regular cleaning and maintenance: Regularly cleaning the steel angles will help remove any dirt, dust, or other contaminants that can contribute to rust formation. Use a mild detergent or cleaning solution and a soft cloth or sponge to clean the surface. After cleaning, make sure the angles are completely dry before applying any protective coating. 5. Monitor and repair damaged coatings: Over time, protective coatings may get damaged due to wear and tear or exposure to harsh conditions. It is essential to monitor the condition of the coatings and repair any damaged areas promptly. This will help maintain the integrity of the protective layer and prevent rust from forming. 6. Consider using stainless steel angles: Stainless steel is highly resistant to rust and corrosion due to its chromium content. If rust prevention is a top priority, you may consider using stainless steel angles instead of regular steel. Although stainless steel angles are typically more expensive, they offer superior durability and a longer lifespan. By implementing these preventive measures, you can significantly reduce the risk of rust formation on steel angles, ensuring their longevity and maintaining their structural integrity.

- Q: How do you calculate the effective length of a steel angle?

- To calculate the effective length of a steel angle, you need to consider two main factors: the actual length of the angle and the stability of the angle's supported members. Firstly, determine the actual length of the steel angle. This can be measured physically or obtained from the specifications provided by the manufacturer. Ensure that you have the accurate length value for the calculation. Next, assess the stability of the angle's supported members. The effective length of the angle is influenced by the conditions under which it is being used and supported. There are three primary support conditions to consider: pinned-pinned, fixed-fixed, and fixed-pinned. For a pinned-pinned support condition, the effective length is equal to the actual length of the angle. This condition assumes that both ends of the angle can freely rotate, resulting in the full length being effective in resisting the applied loads. In a fixed-fixed support condition, the effective length is typically considered as 0.7 times the actual length. This condition assumes that both ends of the angle are rigidly connected, reducing the effective length due to the increased stiffness of the overall system. For a fixed-pinned support condition, the effective length is usually 0.85 times the actual length. In this case, one end of the angle is fixed while the other end can freely rotate, resulting in a reduced effective length compared to the actual length. It is essential to correctly determine the support conditions of the steel angle to accurately calculate its effective length. Additionally, other factors like the angle's material properties, cross-section, and loading conditions should be considered in a comprehensive analysis of the angle's behavior.

- Q: Can steel angles be used for reinforcement in concrete structures?

- Yes, steel angles can be used for reinforcement in concrete structures. Steel angles, also known as L-shaped steel profiles, are commonly used as reinforcing bars in concrete construction. They provide increased strength and stability to the concrete structure, especially in areas where additional support is needed. Steel angles are typically placed within the concrete forms, ensuring proper alignment and spacing, and then embedded in the concrete during the pouring process. This reinforcement helps to prevent cracking and enhance the overall structural integrity of the concrete structure. Steel angles are versatile and can be used in various concrete applications, such as beams, columns, walls, and slabs.

- Q: How do steel angles contribute to the energy efficiency of a building?

- Steel angles can contribute to the energy efficiency of a building by providing structural support and reducing thermal bridging. They can be used to create a strong frame, which allows for larger windows and better natural lighting, reducing the need for artificial lighting during the day. Additionally, steel angles can be used as a barrier to prevent heat transfer between different building materials, minimizing heat loss or gain.

- Q: What are the most common sizes of steel angles?

- The most common sizes of steel angles are typically 3/4 inch, 1 inch, 1-1/4 inch, 1-1/2 inch, and 2 inches.

- Q: Can steel angles be used for agricultural buildings or barns?

- Indeed, agricultural buildings or barns can employ steel angles. The prevailing usage of steel angles in construction is attributed to their robustness and endurance. Specifically, they prove invaluable in agricultural buildings or barns, where the structure must endure substantial burdens and adverse weather conditions. Steel angles can be employed in the framing, bracing, and reinforcement of diverse building constituents, including walls, roofs, and doors. Furthermore, steel angles can be readily fabricated and tailored to fulfill precise design specifications, rendering them a multifaceted option for agricultural buildings or barns.

- Q: What are the design considerations for using steel angles in architectural applications?

- When considering the use of steel angles in architectural applications, there are several important design considerations to keep in mind. First and foremost, it is crucial to understand the structural requirements of the application. Steel angles can provide excellent strength and stability, but their suitability for a particular design will depend on factors such as the load-bearing capacity needed and the structural stability required. It is important to consult with a structural engineer to determine the appropriate size, shape, and thickness of the steel angles to ensure they can safely support the intended loads. Another consideration is the aesthetic appeal of the steel angles. While they are primarily chosen for their structural properties, they can also contribute to the overall design and visual impact of a building. Architects can choose from a variety of finishes, including painted, galvanized, or even stainless steel angles, to achieve the desired look. The shape and arrangement of the angles can also be used creatively to enhance the architectural design and create unique visual effects. Durability is another important design consideration. Steel angles are known for their strength and resistance to corrosion, which makes them suitable for various architectural applications. However, depending on the environmental conditions, additional protective measures may be required to prevent rusting or deterioration over time. This can include applying protective coatings or ensuring proper drainage to prevent water accumulation. Ease of fabrication and installation is also an essential consideration. Steel angles can be easily fabricated into various shapes and sizes, allowing for flexibility in design. They can be cut, welded, or bent to meet the specific requirements of the architectural application. Additionally, their standardized sizes and availability make them relatively easy to source and install. Finally, cost considerations should not be overlooked. Steel angles are generally cost-effective compared to other structural materials, such as wood or concrete. However, the overall cost will depend on factors such as the size, finish, and quantity of steel angles required. It is important to strike a balance between the desired design and the available budget. In conclusion, when considering the use of steel angles in architectural applications, it is essential to carefully assess the structural requirements, aesthetics, durability, ease of fabrication and installation, and cost considerations. By taking these design considerations into account, architects can make informed decisions and ensure the successful integration of steel angles into their designs.

- Q: What are the common welding techniques used for steel angles?

- The common welding techniques used for steel angles include MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and stick welding (Shielded Metal Arc Welding - SMAW). MIG welding, also known as GMAW (Gas Metal Arc Welding), is a widely used technique that involves feeding a continuous wire electrode into the weld pool while an inert gas, such as argon or a mixture of argon and carbon dioxide, is used to shield the weld zone from atmospheric contamination. MIG welding is known for its ease of use, high welding speeds, and ability to handle thicker materials. TIG welding, also known as GTAW (Gas Tungsten Arc Welding), is a more precise welding technique that uses a non-consumable tungsten electrode to create the arc and a separate filler material if necessary. TIG welding provides excellent control over the weld pool and produces high-quality welds with minimal spatter. It is commonly used for thinner materials and applications that require a higher level of precision. Stick welding, also known as SMAW (Shielded Metal Arc Welding), is a versatile and widely used welding process. It involves striking an arc between a flux-coated electrode and the workpiece, creating a weld pool that is protected by the flux coating. Stick welding is known for its portability and ability to handle various materials and thicknesses. It is commonly used in construction, maintenance, and repair work. These welding techniques can be used for steel angles, which are often found in structural applications, such as frames, braces, and supports. The selection of the welding technique depends on factors such as the thickness of the steel angle, the required weld quality, and the specific application. It is important to consider the welding process, proper joint preparation, and welding parameters to ensure a strong and durable weld joint.

Send your message to us

High Quality Stainless angle steel; enqual angle and unequal angle steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords