Unequal Angle Steel with High Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Unequal Angle Steel with High Quality Made in China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel with High Quality Made in China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angle Steel with High Quality Made in China are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Packaging & Delivery ofUnequal Angle Steel with High Quality Made in China:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

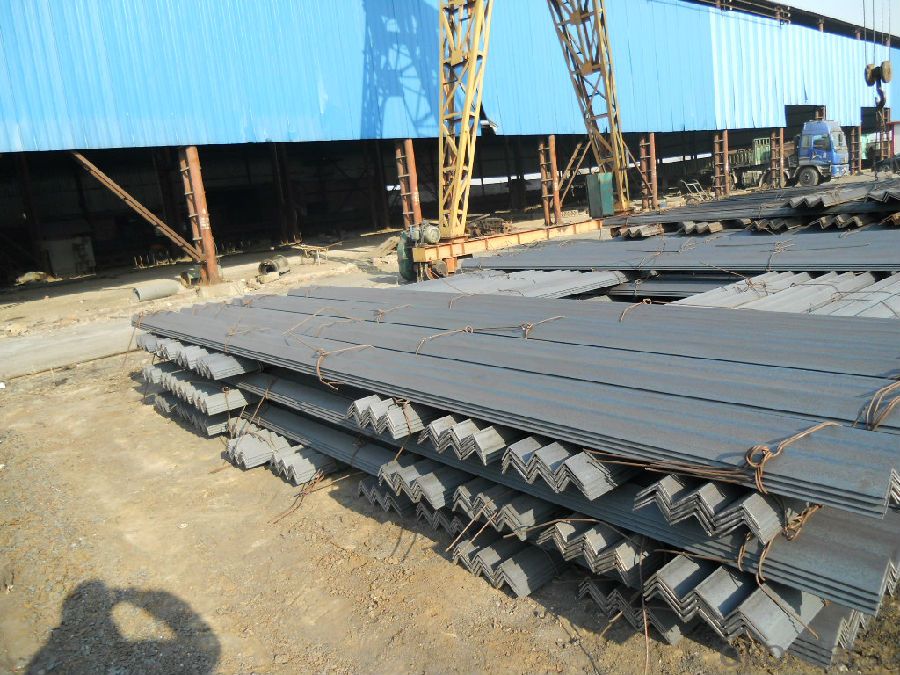

Images:

- Q: How are steel angles defined?

- Steel angles are defined based on the length of their legs, thickness, and their shape, which is typically L-shaped. These angles are commonly used in construction and engineering applications for structural support and framing purposes.

- Q: What are the environmental benefits of using steel angles?

- The environmental benefits of using steel angles include their high strength and durability, which allows for longer lifespan and reduced need for replacement. Steel angles are also recyclable, contributing to a circular economy by reducing the demand for raw materials and energy consumption. Furthermore, steel angles can be manufactured using recycled steel, reducing the carbon footprint and promoting sustainable practices in the construction industry.

- Q: What are steel angles?

- Steel angles are L-shaped structural components made from steel, typically used in construction and engineering projects. These angles have two perpendicular legs that provide strength and stability, making them suitable for various applications such as supporting beams, framing structures, and reinforcing corners. Steel angles come in different sizes and thicknesses to meet specific project requirements and can be easily welded, bolted, or screwed into place.

- Q: What are the common tolerances for steel angles?

- The common tolerances for steel angles vary depending on the specific application and industry standards. However, there are some generally accepted tolerances that are commonly used in the manufacturing and construction industries. For the dimensions of steel angles, the common tolerances are typically ±1/8 inch or ±3mm. This means that the actual dimensions of the angle can deviate by up to 1/8 inch or 3mm from the specified dimensions. These tolerances are usually acceptable for most applications and allow for variations in the manufacturing process. In terms of straightness, steel angles are generally expected to be straight within a certain tolerance. The common straightness tolerance for steel angles is typically specified as a maximum deviation from a straight line over a given length. For example, a common straightness tolerance might be 1/8 inch or 3mm over a 10-foot length. This means that the angle should not deviate more than 1/8 inch or 3mm from a straight line over a 10-foot span. Another important tolerance for steel angles is the squareness or perpendicularity tolerance. This refers to the angle between the two legs of the angle and is typically specified as a maximum deviation from 90 degrees. Common squareness tolerances for steel angles are often ±1 degree or ±0.5 degrees. This means that the angle between the legs should not deviate more than 1 degree or 0.5 degrees from a perfect right angle. It is important to note that these common tolerances are just guidelines and can vary depending on the specific requirements of a project or industry. Additionally, some industries or applications may have more stringent tolerances to ensure precise and accurate angles for their specific needs. Therefore, it is always recommended to consult the relevant standards or specifications for the specific tolerances required for a particular steel angle application.

- Q: What are the typical fabrication processes involved in manufacturing steel angles?

- The typical fabrication processes involved in manufacturing steel angles include cutting, bending, welding, and finishing. The first step in the fabrication process is cutting, where the steel is cut into the desired length or size. This can be done using various methods such as sawing, shearing, or plasma cutting. After cutting, the steel angle may need to be bent to achieve the desired shape. This can be done using a press brake or a rolling machine. Bending helps in creating the required angle and ensuring the steel has the necessary strength and stability. Once the steel angle is cut and bent, it may need to be welded to join the different pieces together. Welding is a crucial process that ensures the strength and integrity of the steel angle. It involves heating the steel to its melting point and fusing the pieces together using a filler material. Finally, the steel angle goes through a finishing process. This may include surface cleaning, grinding, or polishing to remove any imperfections or rough edges. The finishing process helps in enhancing the appearance of the steel angle and also improves its corrosion resistance. Overall, the fabrication processes involved in manufacturing steel angles are cutting, bending, welding, and finishing. These processes are essential in creating steel angles that meet specific design requirements and quality standards.

- Q: How do you protect steel angles from corrosion?

- There are several ways to protect steel angles from corrosion. One of the most common methods is by applying a protective coating such as paint or a specialized corrosion-resistant coating. This creates a barrier between the steel and the surrounding environment, preventing moisture and corrosive agents from reaching the metal surface. Another effective method is to galvanize the steel angles. Galvanization involves coating the steel with a layer of zinc, which acts as a sacrificial anode. The zinc corrodes instead of the steel, providing long-term protection against rust and corrosion. Regular maintenance is also crucial in protecting steel angles from corrosion. This includes cleaning the surface regularly to remove dirt, debris, and other contaminants that can accelerate corrosion. Additionally, inspecting the steel angles for any signs of damage or wear and promptly repairing or replacing any compromised areas can help prevent corrosion from spreading. Using stainless steel angles is another option for corrosion protection. Stainless steel contains a significant amount of chromium, which forms a passive layer on the surface when exposed to oxygen. This passive layer acts as a protective barrier against corrosion, making stainless steel angles highly resistant to rust and corrosion in various environments. Lastly, ensuring proper drainage and ventilation around steel angles is essential to prevent the accumulation of moisture, which can contribute to corrosion. Proper design and installation techniques that minimize contact with water and moisture can significantly extend the lifespan of steel angles and reduce the risk of corrosion.

- Q: What is the typical hardness of steel angles?

- The hardness of steel angles can vary depending on the specific grade and manufacturing process, resulting in a range of hardness levels. Most frequently employed steel angles typically fall within the 120 to 280 range on the Brinell hardness scale. It is worth noting that the hardness of steel angles can be additionally affected by factors like heat treatment, alloy composition, and surface finishing. Consequently, it is advisable to consult the manufacturer's specifications or relevant industry standards to ascertain the exact hardness of a specific steel angle.

- Q: How do steel angles perform under high temperatures?

- Steel angles perform well under high temperatures due to their high melting point and excellent heat resistance. Steel is a widely used material in construction and engineering, known for its structural strength and durability. When exposed to high temperatures, steel angles retain their structural integrity and do not deform or weaken easily. This is because steel has a high melting point, typically around 1370 to 1530 degrees Celsius (2500 to 2800 degrees Fahrenheit), which allows it to withstand extreme heat without significant damage. Additionally, steel has excellent heat resistance, meaning it can dissipate heat efficiently and maintain its stability under high thermal loads. This makes steel angles suitable for applications where elevated temperatures are present, such as in industrial furnaces, power plants, or high-temperature environments. However, it is important to note that the specific performance of steel angles under high temperatures may vary depending on the grade and composition of the steel, as well as the duration and intensity of the heat exposure.

- Q: Can steel angles be used for support frames in industrial machinery?

- Yes, steel angles can be used as support frames in industrial machinery. Steel angles are often chosen for their high strength and durability, making them suitable for providing structural support in heavy-duty applications. They can be easily welded or bolted together to form a sturdy framework that can withstand the weight and forces of industrial machinery.

- Q: Can steel angles be used for manufacturing window frames?

- Indeed, the utilization of steel angles is feasible for the production of window frames. Given their robustness, longevity, and versatility, steel angles are extensively employed in both construction and manufacturing. They furnish a robust structure for windows, capable of enduring the weight and force exerted by the window glass. The assembly of steel angles through welding, bolting, or screwing allows for the creation of a robust and steady window frame. Furthermore, steel angles can be tailored to meet precise design specifications, rendering them suitable for a wide array of window sizes and shapes. All in all, owing to their dependability, strength, and adaptability, steel angles are a favored option for the manufacturing of window frames.

Send your message to us

Unequal Angle Steel with High Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords