Packaging & Delivery

| Packaging Details: | suitable for export with hooks for easy unloading of material with bundle weight |

|---|---|

| Delivery Detail: | 20days after deposit |

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Standard:GB, JIS

Dimensions:45mm to 200mm

Grade:SS400-SS540 Series

Model Number:45mm to 200mm

Type:Equal

Application:for construction

| Packaging Details: | suitable for export with hooks for easy unloading of material with bundle weight |

|---|---|

| Delivery Detail: | 20days after deposit |

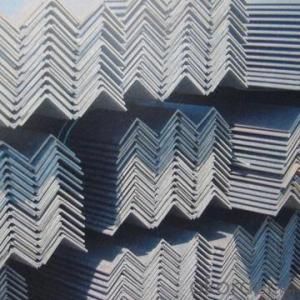

construction material angle iron equal angle steel

1.size: 45--200mm

2.material: SS400,Q235

3.length:6m,9m,12m

4.payment:T/T or Sight L/C

Send your message to us

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords