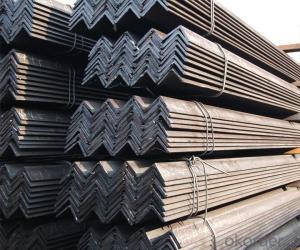

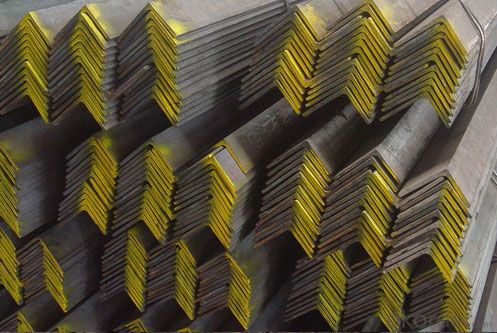

Unequal Steel Angle S235jrg Hot Dip Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Steel Angle S235jrg Hot Dip Galvanized at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Steel Angle S235jrg Hot Dip Galvanized are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Steel Angle S235jrg Hot Dip Galvanized are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specification:GB/EN/ASTM/JIS/ S275JR

Grade:A36,SS400,Q235,Q345,ST37,ST52

Zinc thickness:30-100um(200-600g/m2)

Size: from Size 25--Size 100

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel angles be used for signage or billboards?

- Signage or billboards can indeed utilize steel angles. Due to their versatility and durability, steel angles prove suitable for a range of purposes, including signage and billboards. By offering structural support and stability, they ensure the signage or billboard stays firmly in position. Moreover, steel angles are highly customizable and can be fabricated to accommodate precise design specifications. With the ability to be painted or coated, they can enhance their aesthetic appeal and safeguard against corrosion, guaranteeing long-lasting and resilient outdoor installations. In summary, steel angles serve as a dependable and pragmatic option for signage and billboards.

- Q: How do you maintain and clean steel angles?

- To maintain and clean steel angles, there are a few simple steps you can follow. First, it is important to regularly inspect the angles for any signs of damage or corrosion. If any issues are identified, they should be addressed promptly to prevent further damage. To clean steel angles, start by removing any loose dirt or debris using a soft brush or cloth. This will help prevent scratching the surface. Next, you can use a mild detergent or soap mixed with warm water to clean the angles. Apply the solution using a sponge or cloth, and gently scrub the surface. Avoid using abrasive cleaners or scrub brushes, as they can damage the steel. After cleaning, rinse the angles thoroughly with clean water to remove any soap residue. Make sure to dry the angles completely to prevent water spots or rust formation. You can use a clean cloth or towel for drying, or allow them to air dry. To maintain the steel angles, it is advisable to apply a protective coating or wax. This will help prevent corrosion and maintain their appearance. There are various types of protective coatings available, such as clear lacquers or metal-specific coatings. Follow the manufacturer's instructions for application and reapplication as needed. Additionally, it is important to avoid exposing steel angles to harsh chemicals or environments that can accelerate corrosion. If the angles are located in an area with high humidity or saltwater exposure, regular maintenance and inspection become even more crucial. Overall, routine cleaning, inspection, and proper maintenance will help ensure the longevity and appearance of steel angles.

- Q: Can steel angles be used in high-temperature applications?

- Depending on the alloy and temperature range, steel angles can be utilized in high-temperature scenarios. Stainless steels and heat-resistant alloys, which are specifically engineered for high-temperature applications, possess the ability to endure elevated temperatures without compromising strength or structural integrity. These alloys typically contain elements such as chromium, nickel, or molybdenum, which enhance resistance against corrosion, oxidation, and high temperatures. Nonetheless, it is imperative to acknowledge that not all steel angles are appropriate for high-temperature uses. Ordinary carbon steels, for instance, have a restricted temperature range before experiencing strength loss and becoming vulnerable to deformation or failure. The precise temperature threshold for a specific steel angle relies on factors such as alloy composition, heat treatment, and duration of exposure to high temperatures. To recap, steel angles can be employed in high-temperature applications if they are constructed from suitable alloys specifically designed for such conditions. It is essential to consult materials engineers or experts who can provide guidance on appropriate steel alloys and temperature limits for a given application to ensure performance that is safe and reliable.

- Q: What are the limitations of using steel angles in certain applications?

- One limitation of using steel angles in certain applications is their limited load-bearing capacity. Steel angles are typically used for lighter structural applications where the load is not too heavy. Another limitation is their susceptibility to corrosion, especially in environments with high moisture or chemical exposure. Additionally, steel angles may not be suitable for applications that require high precision or intricate designs, as they are limited in terms of shape and size options.

- Q: What is the typical tolerance for steel angles?

- The typical tolerance for steel angles depends on the specific application and industry standards. However, in general, the industry standard for the tolerance of steel angles is ±1/8 inch or ±3 millimeters. This means that the actual dimensions of the angle can deviate by up to 1/8 inch or 3 millimeters from the specified dimensions. It is important to note that these tolerances may vary for different grades of steel and specific manufacturing processes. Therefore, it is crucial to consult the relevant industry standards or specifications for the specific project to determine the exact tolerance requirements for steel angles in that particular application.

- Q: What is the typical width of a steel angle?

- The typical width of a steel angle can vary depending on the specific application, but common dimensions range from 1 inch to 6 inches.

- Q: What are the different types of steel angles connections for roof trusses?

- There are several types of steel angle connections commonly used for roof trusses, including gusset plate connections, bolted connections, welded connections, and clip angle connections. These connections are designed to provide stability and strength to the truss system, ensuring the overall integrity and safety of the roof structure.

- Q: Are steel angles suitable for vehicle ramps?

- Yes, steel angles are suitable for vehicle ramps. Steel angles are commonly used in construction and are known for their strength and durability. They provide a sturdy and stable surface for vehicles to drive on, making them a suitable choice for vehicle ramps. Additionally, steel angles can be easily welded or bolted together to create a customized ramp design that meets specific requirements. Overall, steel angles are a reliable and practical option for constructing vehicle ramps.

- Q: Can steel angles be used as framing members in buildings?

- Yes, steel angles can be used as framing members in buildings. Steel angles are commonly used in construction as a structural element for framing, bracing, and supporting various components of a building. They offer excellent strength, durability, and load-bearing capacity, making them suitable for a wide range of applications in building construction. Steel angles can be used to create rigid frames, trusses, and connections, providing stability and support to the structure. Additionally, they can be easily welded, bolted, or connected using other fastening methods, allowing for flexible and efficient construction. Overall, steel angles are a versatile and reliable choice for framing members in buildings.

- Q: Can steel angles be used in electrical installations?

- Yes, steel angles can be used in electrical installations. Steel angles are commonly used as structural supports for various electrical components, such as conduit pipes, junction boxes, and electrical panels. They provide a sturdy and durable framework for mounting and securing these components, ensuring proper installation and safety. Additionally, steel angles are versatile and can be easily customized or modified to fit specific electrical installation requirements.

Send your message to us

Unequal Steel Angle S235jrg Hot Dip Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords