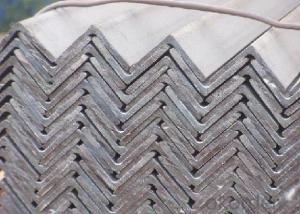

S235JR Angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering S235JR Angle, angle steel, galvanized angle steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

S235JR Angle, angle steel, galvanized angle steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's S235JR Angle, angle steel, galvanized angle steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description:

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse.

Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two.

Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 312.5px for large angle steel, 312.5px - 125px for the medium angle, length of 125px for smallangle.

Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series.

Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m.

Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125

Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel angles be used in the construction of agricultural buildings?

- Yes, steel angles can be used in the construction of agricultural buildings. Steel angles are commonly used as structural components for framing, bracing, and supporting various elements in agricultural buildings such as walls, roofs, and machinery. They provide strength, stability, and durability, making them suitable for withstanding the load and environmental conditions typically encountered in agricultural settings.

- Q: Are steel angles cost-effective?

- Yes, steel angles are generally considered cost-effective due to their durability, versatility, and relatively low production costs. They offer high strength-to-weight ratios, allowing for efficient material usage in construction projects. Additionally, steel angles can be easily fabricated, installed, and maintained, resulting in reduced labor and maintenance costs in the long run.

- Q: Can steel angles be used in residential construction?

- Indeed, residential construction can make use of steel angles. These versatile structural elements find widespread application in various construction projects, including residential buildings. They are commonly employed for framing, reinforcing, and providing structural support in walls, roofs, and floors. In residential construction, steel angles are favored due to their notable strength, durability, and capacity to withstand heavy loads. Their ease of installation, whether by welding, bolting, or screwing, renders them suitable for a wide array of construction endeavors. Furthermore, the corrosion resistance of steel angles can be enhanced through galvanization or coating, assuring their longevity. In essence, steel angles present a dependable and cost-effective option for residential construction.

- Q: What are the common finishes available for steel angles?

- The desired aesthetic appeal and level of protection required will determine the available finishes for steel angles. Common finishes include: 1. Mill finish: The steel angle is left in its natural state after manufacturing, resulting in a rough, gray appearance with minimal corrosion resistance. 2. Hot-dip galvanized: By immersing the steel angle in molten zinc, a protective coating is created on the surface. This finish provides excellent corrosion resistance and is suitable for outdoor applications in harsh environments. 3. Powder coating: Dry powder is applied to the steel angle, then heated and cured to create a durable and decorative coating. Powder coating offers a wide range of colors and textures, along with good corrosion resistance. 4. Painted finish: Various types of paint, such as epoxy, enamel, or acrylic-based coatings, can be used to paint steel angles. Painting provides a decorative finish and can offer some degree of corrosion resistance, depending on the paint type and quality. 5. Stainless steel: Stainless steel angles have a distinct finish that is resistant to corrosion, staining, and rust. They are commonly used in industries like food processing and medicine, where hygiene, aesthetics, and longevity are important. When choosing the appropriate finish, it is important to consider the specific requirements of your project, including the environment and intended use of the steel angle. Consulting with a steel supplier or expert can help determine the best finish for your needs.

- Q: Can steel angles be used in architectural lighting installations?

- Yes, steel angles can be used in architectural lighting installations. Steel angles provide structural support and can be used to mount lighting fixtures securely. They are often used in applications where durability and strength are important, making them suitable for architectural lighting installations.

- Q: Can steel angles be used in the construction of transmission towers?

- Indeed, transmission towers can incorporate steel angles in their construction. Due to their immense strength, durability, and adaptability, steel angles are frequently employed as structural components in a variety of construction projects. In the realm of transmission tower construction, steel angles are frequently utilized to provide the necessary support and stability. They serve multiple functions, such as bracing and forming cross arms, alongside other crucial structural elements of the tower. These angles are typically crafted from high-strength steel, allowing them to endure the heavy loads and harsh environmental conditions to which transmission towers are subjected. Moreover, steel angles can be effortlessly fabricated, connected, and erected, rendering them an economically viable choice for transmission tower construction.

- Q: How do you join two steel angles together?

- There are several methods available for joining two steel angles together, depending on the specific application and requirements. Here are a few commonly used techniques: 1. Welding: The most widely used method for joining steel angles is welding. This involves heating the joint to a high temperature and melting a compatible metal filler material to fuse the angles together. Welding creates a strong and permanent bond, but it requires specialized equipment and expertise, so it is usually carried out by trained professionals. 2. Bolting: Another option is to use bolts or screws to connect the steel angles. This involves drilling holes in both angles and securing them with appropriate fasteners. Bolting allows for easier disassembly and modification if necessary, but it may not offer the same level of strength as welding. 3. Riveting: Riveting is a technique that utilizes metal pins or bolts called rivets to hold the steel angles together. It involves drilling holes in the angles and inserting the rivets, which are then hammered or pressed to create a permanent joint. Riveting is commonly employed in structural applications where high strength and load-bearing capacity are essential. 4. Adhesive bonding: In certain cases, adhesive bonding can be used to join steel angles. Specialized adhesives are applied to the joint surfaces, and then the angles are pressed together and left to cure. This method can result in a clean and visually appealing bond, although it may not possess the same strength as other mechanical methods. When choosing a method to join steel angles, it is crucial to consider factors such as load-bearing requirements, structural integrity, accessibility, and the specific conditions of the application. Consulting with a structural engineer or a professional in the field can help determine the most suitable technique for your particular needs.

- Q: How do steel angles perform under cyclic or alternating loading conditions?

- Steel angles generally perform well under cyclic or alternating loading conditions. Due to their structural shape and material properties, steel angles have good resistance to fatigue and can withstand repeated loading without significant loss of strength or deformation. Their high strength and stiffness make them suitable for applications that involve cyclic loading, such as in construction and engineering structures. Additionally, steel angles have the advantage of being relatively easy to fabricate and install, making them a popular choice in various industries.

- Q: Can steel angles be used for bracing?

- Certainly! Bracing can be achieved using steel angles. These angles are widely employed in construction and engineering ventures to furnish structural support and reinforcement. Their versatility allows for effortless welding or bolting, rendering them adaptable to diverse applications, including bracing. Owing to their inherent strength and rigidity, steel angles excel at bestowing stability and withstanding lateral forces. They are frequently utilized to brace columns, beams, and other structural components, thereby augmenting the overall robustness and stability of the edifice.

- Q: Are steel angles available in custom sizes?

- Yes, steel angles are available in custom sizes.

Send your message to us

S235JR Angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords