S235JR Equal steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

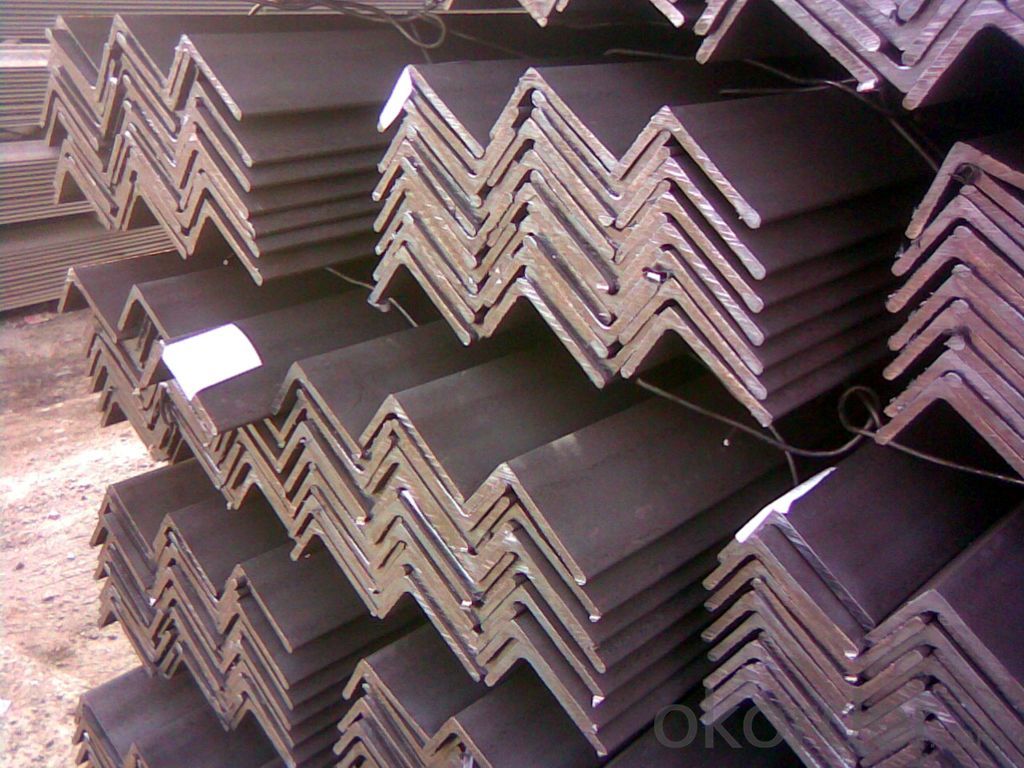

OKorder is offering S235JR Equal steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

S235JR Equal steel angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

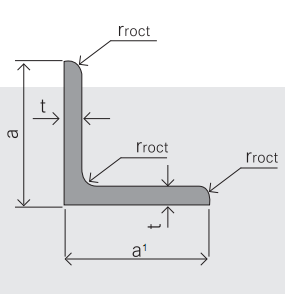

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

4.Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5.aterial details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of GB Equal Structural Angle

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of GB Equal Structural Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel angles be used for bracing purposes?

- Indeed, for bracing objectives, steel angles can be employed. Owing to their robustness and longevity, steel angles are frequently utilized as structural constituents in construction. They commonly serve as supplementary reinforcement and stability enhancers for different structures, encompassing edifices, bridges, and industrial machinery. By effortlessly bolting or welding them to the principal framework of a structure, steel angles offer supplementary rigidity and resist various forces such as compression, tension, and lateral loads. Their adaptable shape facilitates an extensive array of bracing applications, rendering them a favored option for bracing intents in construction and engineering ventures.

- Q: Can steel angles be used in the construction of warehouses?

- Indeed, warehouses can utilize steel angles for their construction. Owing to their robustness and endurance, steel angles are frequently employed as structural elements in buildings and warehouses. They offer stability and bolster the entire structure, rendering them appropriate for diverse construction purposes. In the realm of warehouse construction, steel angles serve as framing components, columns, beams, and supports, contributing to the establishment of a sturdy and dependable edifice. Furthermore, steel angles exhibit adaptability and can be readily tailored and manufactured to satisfy precise design specifications, thus establishing their prominence as a favored option in warehouse construction ventures.

- Q: What is the maximum temperature steel angles can withstand?

- The specific grade of steel being used determines the maximum temperature that steel angles can endure. In general, carbon steel can withstand temperatures of approximately 1000°C (1832°F) before its structural integrity begins to deteriorate. Nonetheless, the duration of exposure to high temperatures, the applied load, and the cooling rate after exposure are also influential in establishing the maximum temperature that steel angles can tolerate. To ensure that the steel angles are used within their safe temperature limits, it is advisable to consult the manufacturer's specifications or a structural engineer.

- Q: What is the maximum allowable tensile stress for a steel angle?

- The maximum allowable tensile stress for a steel angle depends on the specific grade and type of steel being used, as well as any relevant industry standards or regulations that may apply. Therefore, it is not possible to provide a specific answer without further information.

- Q: What are the typical uses for steel angles?

- Steel angles have a wide range of uses in various industries and construction projects. One of the most common applications is in structural framing, where steel angles are used to provide additional strength and support to buildings and other structures. They are often used to create bracing, reinforcing, and framing elements in construction projects, such as beams, columns, and trusses. Another typical use for steel angles is in manufacturing and fabrication. They are utilized in the production of machinery, equipment, and vehicles, where their ability to withstand heavy loads and resist bending or warping makes them an ideal choice. Steel angles can be used as frames, supports, or brackets in the construction of various industrial equipment and machinery. Steel angles are also commonly used in the manufacturing of furniture, especially in metalwork and carpentry. They can be used as corner brackets or connectors to provide stability and strength to furniture pieces like tables, chairs, and shelves. Additionally, steel angles are often used in the construction of storage racks and shelving systems, as they offer durability and stability for holding heavy loads. In the transportation industry, steel angles are frequently used in the manufacturing of trailers, truck beds, and frames for various vehicles. Their high strength and resistance to impact and vibrations make them suitable for these applications, ensuring the structural integrity and longevity of the vehicles. Overall, the typical uses for steel angles span across a wide range of industries and applications. Their versatility, strength, and durability make them a popular choice for structural support, manufacturing, furniture construction, and various other projects where robustness and stability are required.

- Q: How are steel angles protected against corrosion?

- Steel angles are protected against corrosion through various methods such as galvanization, painting, or applying a protective coating. These protective measures create a barrier between the steel surface and corrosive elements, preventing direct contact and ensuring the longevity and durability of the steel angles.

- Q: How do steel angles perform in corrosive or acidic environments?

- Steel angles exhibit strong performance in environments that are corrosive or acidic, but their effectiveness is contingent upon the type of steel employed and the specific conditions of the environment. For instance, stainless steel angles possess exceptional resistance to corrosion and can endure exposure to acidic environments without substantial deterioration. This is due to their high chromium content, which generates a protective layer on the surface upon contact with oxygen, thereby impeding further corrosion. Conversely, carbon steel angles demonstrate heightened vulnerability to corrosion in corrosive or acidic environments. They lack the same degree of chromium content and protective layer, rendering them more susceptible to rusting and degradation when confronted with such circumstances. Consequently, in these scenarios, supplementary protective coatings or treatments, such as galvanization or painting, may be necessary to augment their corrosion resistance. Moreover, the severity and concentration of corrosive or acidic substances within the environment can also influence the performance of steel angles. Elevated concentrations of acids or corrosive substances can expedite the corrosion process, even for stainless steel angles. Consequently, it is essential to meticulously evaluate the specific environment and select the appropriate steel material and protective measures accordingly to ensure optimal performance and longevity in corrosive or acidic environments.

- Q: What are the design considerations for using steel angles in architectural applications?

- Some design considerations for using steel angles in architectural applications include structural stability, load-bearing capacity, aesthetic appeal, corrosion resistance, and ease of installation. Steel angles are commonly used to provide support, reinforcement, and stability to various architectural elements such as beams, columns, and frames. The selection of the appropriate size, thickness, and grade of steel angle is crucial to ensure the structural integrity and safety of the building. Additionally, architects may consider the visual impact of steel angles, as they can be exposed or concealed depending on the design intent. The corrosion resistance properties of the steel angles should also be taken into account, especially in applications where exposure to moisture or harsh environments is expected. Lastly, the ease of installation and compatibility with other building materials should be considered to streamline the construction process.

- Q: Can steel angles be used for stair stringers?

- Yes, steel angles can be used for stair stringers. Steel angles are commonly used in construction for their strength and durability. When used as stair stringers, steel angles provide the necessary support and stability for the stairs. They can be easily cut and welded to the desired shape and size, making them a versatile option for stair construction. Additionally, steel angles are resistant to rot, termites, and other forms of damage, ensuring the longevity of the stair structure. However, it is important to consult with a structural engineer or a professional contractor to ensure that the steel angles meet the specific requirements and load-bearing capacity for the intended stair design.

- Q: What are the common methods of surface cleaning for steel angles?

- Steel angles can be cleaned using various methods to remove dirt, rust, paint, and other contaminants, ensuring a smooth and clean surface. Mechanical cleaning is a widely used method that involves scrubbing the surface with abrasive materials like sandpaper, wire brushes, or abrasive pads. This is effective for spot cleaning or smaller areas. Chemical cleaning, on the other hand, utilizes chemicals or solvents to dissolve or loosen contaminants. A cleaning solution is applied directly to the steel angles and then scrubbed with a brush or cloth. This method is useful for larger areas or stubborn stains and paints. Power washing, also known as pressure washing, is another popular method for cleaning steel angles. It involves using a high-pressure water jet to remove dirt, dust, and loose particles. Power washing is efficient for large areas or for eliminating loose rust or paint. Abrasive blasting is a highly effective method that utilizes compressed air to propel abrasive materials like sand or steel grit onto the surface of the steel angles. This method is particularly useful for removing heavy rust, paint, or scale, leaving a clean and smooth finish. It is important to consider the condition of the steel angles and the desired level of cleanliness when choosing a cleaning method. Some methods may be more suitable for specific applications and may require specialized equipment. Furthermore, it is crucial to follow proper safety precautions, including wearing protective gear and ensuring adequate ventilation, when using any cleaning method.

Send your message to us

S235JR Equal steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords