Equal Steel Angle S235JR Hot Rolled Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | In bundles and load in container, if large quantity, ship by bulk vessel. Also can be done according to customer's request |

| Delivery Detail: | Within 30 days after receipt of L/C or deposit by T/T |

Specifications

S235jr hot rolled equal steel angle

1.Grade:A36,Q235,SS400

2.Surface:galvanized,black,painted

3.Type: equal & unequal

1.Product Description

Products | S235jr hot rolled equal steel angle |

Grade | Q235,SS400B,A36,S255JR.ect |

Specification | 20*20--200*200mm. |

Length | 6m, 12m |

Technique | Hot rolled |

Application | Widely used in various building structure and engineering structure, such as the beam, bridges, transmission tower, lifting transportation machinery, ship, industrial furnace, reaction tower, container frame and warehouse.etc |

Payment | 100% irrevocable L/C at sight 30% T/T prepaid and the balance against the copy of B/L |

Reference sizes,

Size | Weight | Size | Weight | Size | Weight |

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

25*3 | 1.124 | 70*6 | 6.406 | 100*16 | 23.257 |

25*4 | 1.459 | 70*7 | 7.398 | 110*8 | 13.532 |

30*3 | 1.373 | 70*8 | 8.373 | 110*10 | 16.69 |

30*4 | 1.786 | 75*5 | 5.818 | 110*12 | 19.782 |

40*3 | 1.852 | 75*6 | 6.905 | 110*14 | 22.809 |

40*4 | 2.422 | 75*7 | 7.976 | 125*8 | 15.504 |

40*5 | 2.967 | 75*8 | 9.03 | 125*10 | 19.133 |

50*3 | 2.332 | 75*10 | 11.089 | 125*12 | 22.696 |

50*4 | 3.059 | 80*6 | 7.736 | 125*14 | 26.193 |

50*5 | 3.77 | 80*8 | 9.658 | 140*10 | 21.488 |

50*6 | 4.465 | 80*10 | 11.874 | 140*12 | 25.522 |

60*5 | 4.57 | 90*8 | 10.946 | 140*14 | 29.49 |

60*6 | 5.42 | 90*10 | 13.476 | 160*12 | 29.391 |

63*4 | 3.907 | 90*12 | 15.94 | 160*14 | 33.987 |

63*5 | 4.822 | 100*8 | 12.276 | 160*16 | 38.518 |

63*6 | 5.721 | 100*10 | 15.12 | 160*18 | 48.63 |

63*8 | 7.469 | 100*12 | 17.898 | 180*18 | 48.634 |

70*5 | 5.397 | 100*14 | 20.611 | 200*24 | 71.168 |

2.Packaging & Shipping:

In bundles, load into container, if large quantity, ship by bulk vessel.

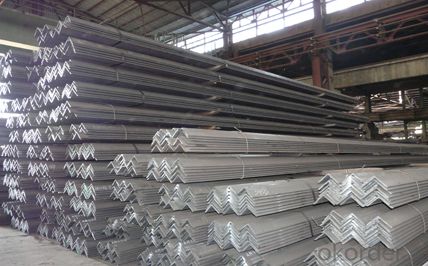

3. Relevant product pictures:

- Q: What are the different types of steel angles used in transmission line towers?

- There are several different types of steel angles that are commonly used in transmission line towers. These angles are specifically designed to provide structural support and stability to the towers, ensuring that they can withstand the weight of the transmission lines and the environmental conditions they are exposed to. 1. Equal leg angle: This type of angle has two legs of equal length, forming a right angle. It is a widely used angle in transmission line towers due to its simple design and ease of fabrication. 2. Unequal leg angle: As the name suggests, this type of angle has two legs of unequal length, forming an acute or obtuse angle. Unequal leg angles are used in transmission line towers when there is a need for specific load-bearing requirements. 3. Bulb angle: Bulb angles have a unique shape with a bulbous end that provides additional strength and stability. This type of angle is often used in critical areas of transmission line towers that require extra support, such as at the base or at connection points. 4. Lipped angle: Lipped angles have an extended lip on one side, which increases their load-bearing capacity. This type of angle is commonly used in transmission line towers where there is a need for increased strength and stability. 5. Back-to-back angle: Back-to-back angles are two equal leg angles joined back-to-back with their flanges touching. This configuration creates a wider angle that offers enhanced load-bearing capabilities and resistance to bending. It is often used in transmission line towers where higher loads or longer spans need to be supported. Each type of steel angle used in transmission line towers has its own unique characteristics and advantages, allowing engineers to select the most appropriate angle for the specific requirements of the tower design. These angles are carefully chosen to ensure the overall strength, stability, and durability of the transmission line tower, ultimately contributing to the reliable and efficient transmission of electricity.

- Q: What is the minimum thickness for a steel angle beam?

- The minimum thickness for a steel angle beam depends on various factors such as the load it needs to support, the length of the beam, and the specific steel grade being used. Generally, the minimum thickness for a steel angle beam is determined by structural engineers or professionals in the field, who consider the specific application and design requirements. Steel angle beams are commonly used in construction, framing, and other structural applications. They are designed to provide support and stability, particularly in load-bearing situations. The thickness of the steel angle beam is crucial to ensure its strength and ability to bear the intended load without deformation or failure. To determine the minimum thickness, engineers consider factors such as the maximum load that the beam will experience, the length of the beam, the material properties of the steel being used, and the safety factor required for the application. They use mathematical calculations and structural analysis to determine the appropriate thickness that will meet the necessary structural requirements. It is important to note that there are specific industry standards and building codes that must be followed when designing and constructing steel angle beams. These standards provide guidelines and requirements for minimum thickness, as well as other aspects such as tolerances, dimensions, and connection details. Therefore, it is always recommended to consult with a qualified structural engineer or professional in the field to determine the minimum thickness for a steel angle beam based on the specific requirements of the project. They will consider all relevant factors and ensure that the beam is designed and constructed to provide the necessary strength and safety.

- Q: Can steel angles be used in framing?

- Yes, steel angles can be used in framing. Steel angles are commonly used in construction for framing purposes due to their strength, durability, and versatility. They are often used to provide structural support and stability in various building applications, including framing walls, floors, roofs, and other structural elements.

- Q: Are steel angles suitable for rooftop installations?

- Yes, steel angles are suitable for rooftop installations. Steel angles are commonly used in construction for their strength and durability. They are particularly useful for rooftop installations due to their ability to provide structural support and stability. Steel angles can be used to secure various rooftop equipment such as solar panels, HVAC units, communication antennas, and satellite dishes. Additionally, steel angles are resistant to weathering, corrosion, and fire, making them a reliable choice for rooftop installations.

- Q: How do steel angles compare to wooden or concrete structural elements?

- Steel angles have several advantages over wooden or concrete structural elements. Firstly, steel angles are known for their exceptional strength and durability. They can bear heavy loads and resist deformation, making them ideal for supporting large structures or bridges. In comparison, wooden elements are prone to rot, warping, and degradation over time, while concrete elements may develop cracks or suffer from corrosion. Additionally, steel angles offer a high level of versatility in terms of design and construction. They can be easily fabricated into various shapes and sizes, allowing for customized solutions for different structural needs. This flexibility is not easily achievable with wooden or concrete elements, which are limited by their natural properties and construction techniques. Moreover, steel angles provide excellent fire resistance compared to wooden elements, which are highly flammable. Steel does not burn, and its structural integrity remains intact even in high-temperature environments. Concrete also offers fire resistance, but steel angles have the advantage of being lightweight, reducing the overall load on the structure. Another significant advantage of steel angles is their resistance to pests, such as termites or rodents, which can severely damage wooden structures. Steel is impervious to these threats, ensuring long-term stability and reducing maintenance costs. However, there are some drawbacks to using steel angles as well. One of the main concerns is the potential for corrosion, especially in environments with high moisture or chemical exposure. Regular maintenance, including protective coatings or galvanization, is necessary to prevent rust formation and maintain the steel's structural integrity. Furthermore, steel angles tend to have a higher upfront cost compared to wooden elements. However, their long-term durability and reduced maintenance requirements often result in cost savings over time. In conclusion, steel angles offer numerous advantages over wooden or concrete structural elements, including superior strength, versatility, fire resistance, pest resistance, and long-term durability. However, considerations such as corrosion prevention and initial costs should be taken into account when deciding on the most suitable structural material for a specific project.

- Q: How do steel angles contribute to the durability of a structure?

- Steel angles contribute to the durability of a structure in several ways. First and foremost, steel angles are known for their high strength and load-bearing capacity. They are commonly used in construction to provide added support and stability to various structural elements such as beams, columns, and trusses. The rigidity and strength of steel angles ensure that the structure can withstand heavy loads, impacts, and external forces. This is especially crucial in buildings that are exposed to extreme weather conditions, seismic activities, or high winds. By distributing the load evenly, steel angles help prevent excessive deflection, bending, or deformation that could compromise the integrity and longevity of the structure. Moreover, steel angles are corrosion-resistant, making them ideal for structures that are exposed to moisture, humidity, or harsh environments. Unlike other building materials, steel does not rot, decay, or warp over time. It maintains its structural integrity for an extended period, reducing the need for frequent repairs and replacements. In addition to their strength and corrosion resistance, steel angles also contribute to the durability of a structure through their versatility. They can be easily customized and fabricated into various shapes and sizes, allowing for efficient construction and design flexibility. This adaptability ensures that steel angles can be efficiently integrated into different architectural and engineering requirements, enhancing the overall durability and functionality of the structure. Overall, the use of steel angles in construction significantly enhances the durability of a structure. Their high strength, load-bearing capacity, corrosion resistance, and versatility all contribute to the overall stability, longevity, and structural integrity of the building, ensuring it can withstand various challenges and maintain its durability over time.

- Q: Can steel angles be used in high-rise buildings?

- Yes, steel angles can be used in high-rise buildings. Steel angles are commonly used as structural elements in building construction due to their strength and versatility. They can be used for various purposes such as supporting beams and columns, providing stability, and reinforcing connections in high-rise buildings.

- Q: What is the typical density of steel angles?

- Steel angles can have varying densities depending on the particular steel type and grade employed. On average, their density falls within the range of 7.7 to 8.1 grams per cubic centimeter (g/cm³), or equivalently 7700 to 8100 kilograms per cubic meter (kg/m³). In comparison to other substances, steel angles possess a notably high density, imparting strength and durability for a multitude of structural and construction purposes.

- Q: Can steel angles be used as handrails?

- Certainly! Handrails can indeed be made from steel angles. These angles, frequently employed in construction, offer commendable robustness and durability for this purpose. Their installation is hassle-free, and they afford users a secure and steady hold. Nonetheless, it is crucial to verify that these steel angles adhere to safety regulations and abide by the building codes of the locality. This ensures that the handrails can effectively withstand the requisite weight and bestow adequate protection upon those who use them.

- Q: What are the different grades of steel used in angle production?

- There are several different grades of steel that are commonly used in angle production. The specific grade of steel chosen depends on the intended application and the required strength and durability. Some of the most common grades of steel used in angle production include: 1. A36 steel: This is a low carbon steel that is commonly used in general construction and engineering applications. It offers good strength, weldability, and machinability, making it a versatile choice for angle production. 2. A572 steel: This is a high-strength, low-alloy steel that is often used in structural applications such as bridges, buildings, and heavy machinery. It provides excellent strength and toughness, making it suitable for angles that need to withstand heavy loads and extreme conditions. 3. A588 steel: This is a weathering steel that is designed to form a protective rust-like coating when exposed to the elements. It is commonly used in outdoor structures such as bridges, buildings, and sculptures. A588 steel angles are resistant to corrosion and offer good strength and durability. 4. A500 steel: This is a cold-formed, welded carbon steel that is often used in structural applications such as frames, supports, and braces. It is available in different grades, including A, B, and C, with varying strength levels. A500 steel angles are commonly used in construction projects where high strength and stability are required. 5. Stainless steel: This is a corrosion-resistant steel alloy that contains a minimum of 10.5% chromium. It is often used in applications that require resistance to corrosion, heat, and chemical exposure. Stainless steel angles are commonly used in industries such as food processing, chemical processing, and marine environments. These are just a few examples of the different grades of steel used in angle production. The selection of the appropriate grade depends on factors such as the intended application, desired strength and durability, and environmental conditions. It is important to consult with a steel expert or engineer to determine the most suitable grade of steel for a specific angle production project.

Send your message to us

Equal Steel Angle S235JR Hot Rolled Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords