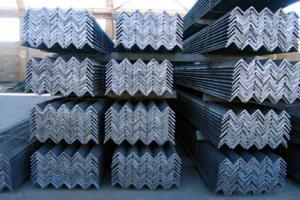

Equal Angle Bar, Steel Galvanized Angle Iron, Mild Steel Equal Angle

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Equal Angle Bar, Steel Galvanized Angle Iron, Mild Steel Equal Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel Hot Rolled Unequal Perforated Steel Angle Iron are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Bar, Steel Galvanized Angle Iron, Mild Steel Equal Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc mild angle steel |

Grade | Q235, Q345, SS400, A36, S235JR,S355JR, ST37-2,ST52, etc |

Equal Angle steel | Type: 2.5#-20# Size: 25-200mm Thickness: 3.0-20mm Weight: 0.597-71.168kg/m |

Unequal Angle steel | Type: 2.5/1.6-20/12.5 Long Side: 25-200mm Short Side: 16-125mm Thickness: 3.0-18mm Weight: 1.687-43.588kg/m |

Length | 5.8-12.0m OR according to client's request |

Element Contect | C<0.22% Si:<0.16% Mn: 0.30—0.65% P<0.060% S<0.060% |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel angles be used for signage or billboards?

- Yes, steel angles can be used for signage or billboards. Steel angles are versatile and durable, making them suitable for various applications, including signage and billboards. They provide structural support and stability, ensuring that the signage or billboard remains securely in place. Additionally, steel angles can be easily customized and fabricated to meet specific design requirements. They can be painted or coated to enhance their appearance and protect against corrosion, ensuring longevity and durability for outdoor installations. Overall, steel angles are a reliable and practical choice for signage and billboards.

- Q: How do steel angles differ from steel channels?

- Steel angles and steel channels differ in their structural shape. Steel angles have an L-shaped cross-section, consisting of two legs that are perpendicular to each other. On the other hand, steel channels have a U-shaped cross-section, with a flat bottom and two flanges on the sides. These different shapes make steel angles suitable for providing structural support and stability in various applications, while steel channels are often used for framing and reinforcement purposes.

- Q: How do steel angles contribute to the overall stability of a truss system?

- Steel angles play a crucial role in enhancing the overall stability of a truss system. Truss systems are widely used in various structural applications, such as bridges and buildings, to provide support and distribute loads efficiently. The steel angles within a truss system contribute to its stability in several ways. Firstly, steel angles are commonly used as diagonal members within the truss system. These diagonal members help to resist both tensile and compressive forces that act on the structure. By strategically placing these steel angles, the truss system gains resistance against lateral loads, such as wind or seismic forces, which can cause the structure to sway or collapse. The diagonal angles effectively transfer these loads to the vertical and horizontal members of the truss, ensuring the stability of the entire system. Additionally, steel angles also provide stability by preventing the buckling or twisting of truss members. Buckling refers to the sudden failure of a structural member under compressive stress, while twisting refers to the rotational deformation of a member due to lateral forces. By incorporating steel angles as bracing elements, the truss system becomes more resistant to these types of deformations. The angles act as rigid supports, preventing the members from buckling or twisting, thus enhancing the overall stability of the truss system. Furthermore, steel angles help to increase the rigidity of the truss system. Rigidity refers to the stiffness and resistance to deformation of a structure. By connecting various truss members with steel angles, the overall rigidity of the truss system is improved. This increased rigidity enables the truss to bear heavier loads and provides overall stability and durability to the structure. In conclusion, steel angles are essential in contributing to the overall stability of a truss system. They provide resistance against lateral loads, prevent buckling and twisting of members, and increase the rigidity of the structure. By incorporating steel angles strategically within a truss system, engineers can ensure the stability and strength of the structure, making it capable of withstanding various external forces.

- Q: Can steel angles be painted or coated after installation?

- Yes, steel angles can be painted or coated after installation. Painting or coating steel angles after installation can provide additional protection against corrosion and enhance their aesthetic appeal. Prior to painting or coating, it is important to clean and prepare the surface by removing any dirt, rust, or contaminants. This can be done through techniques such as sandblasting, wire brushing, or using chemical cleaners. Once the surface is clean and dry, a suitable primer can be applied to promote adhesion and prevent corrosion. After the primer has dried, a final coat of paint or coating can be applied using a brush, roller, or spray. It is essential to choose a paint or coating that is specifically designed for steel and offers the desired level of protection and durability.

- Q: What are the common design codes or standards for steel angles?

- Structural design of steel angles is governed by various design codes and standards, which guarantee their compliance with safety and performance criteria. The American Institute of Steel Construction (AISC) Manual of Steel Construction is widely recognized as a crucial design code for steel angles. This manual offers comprehensive guidelines and specifications for the design, fabrication, and erection of steel structures, encompassing angles as well. It provides intricate details regarding design strength, allowable stress levels, and geometric properties of angles. Besides the AISC Manual, other design codes and standards may also apply depending on the specific project and location. These include internationally recognized standards such as the Eurocode, British Standards (BS), and Australian Standards (AS). Each of these standards may have slight variations in their requirements for steel angle design and utilization. Therefore, referring to the relevant standard for a specific project is of utmost importance. Moreover, the American Society for Testing and Materials (ASTM) has established standards for the physical and mechanical properties of steel angles. These standards guarantee that the angles satisfy certain quality and performance requirements. Among the most commonly utilized ASTM standards for steel angles is ASTM A36, which outlines general requirements for carbon structural steel. To ensure structural integrity and reliability, common design codes and standards for steel angles provide guidance on crucial factors such as load capacity, strength, and safety considerations. By adhering to these codes and standards, steel angles are designed and employed in a manner that promotes their structural soundness and dependability.

- Q: What are the different types of steel angles used in shipbuilding?

- Various structural purposes in shipbuilding commonly utilize several types of steel angles. These angles are typically crafted from high-strength steel and are intended to confer strength and stability to the ship's structure. Presented below are different steel angle varieties utilized in shipbuilding: 1. Bulb Angles: Specifically designed for ship hull construction, these angles possess a bulbous shape on one side. This unique shape aids in load distribution while adding further strength and stability to the hull structure. 2. L-Shaped Angles: Also known as unequal angles, L-shaped angles find extensive usage in shipbuilding for framing and bracing requirements. With one leg longer than the other, these angles accommodate various applications necessitating varying lengths. 3. Equal Angles: Commonly referred to as L-sections, equal angles consist of two legs of identical length. Shipbuilding extensively employs them for framing and supporting structures, as they confer uniform strength. Their versatility extends to applications such as bulkhead framing and deck support. 4. Flat Bars: While technically not angles, flat bars are frequently employed in shipbuilding for comparable purposes. These bars possess a rectangular cross-section and are primarily used for reinforcement, framing, and connecting different structural components. 5. T-Sections: T-sections, or T-angles, feature a T-shaped cross-section and serve in shipbuilding for structural framing, reinforcement, and component connection. The vertical leg of the T-section imparts additional strength and stability to the structure. 6. Z-Sections: Z-sections, or Z-angles, possess a Z-shaped cross-section and fulfill various shipbuilding purposes such as framing, bracing, and structural support. These angles offer excellent load-bearing capacity and are frequently utilized when maximum strength is required. Ultimately, the selection of steel angles in shipbuilding hinges upon the specific requirements of the structure, encompassing load-bearing capacity, structural design, and intended purpose. The aforementioned steel angle types provide a vast array of options to cater to the diverse demands of ship construction.

- Q: Can steel angles be used for stairs in industrial settings?

- In industrial settings, stairs can indeed utilize steel angles. The construction industry often employs steel angles for a wide range of purposes, including staircases. Their strength and durability make them particularly well-suited for industrial environments where safety and robustness are paramount. By providing structural support and stability, steel angles enable staircases to endure heavy loads and frequent usage. Moreover, the ease of welding steel angles ensures that the resulting staircase is secure and long-lasting. Additionally, steel angles offer versatility, allowing for customization to meet specific design and spatial needs. As a result, steel angles are an appropriate option for stairs in industrial settings.

- Q: What are the different methods for protecting steel angles from corrosion?

- There are several methods available for protecting steel angles from corrosion. 1. Galvanization: Galvanization is a widely used method where a layer of zinc is applied to the surface of the steel angle. This zinc layer acts as a sacrificial anode, meaning it corrodes first before the steel, protecting it from rust. This method provides excellent protection and is commonly used in outdoor applications such as construction and infrastructure. 2. Paint coating: Applying a paint coating to the steel angle can provide an effective barrier against corrosion. The paint forms a protective layer that prevents moisture and oxygen from reaching the steel surface, thus inhibiting the corrosion process. It is important to use high-quality, corrosion-resistant paints for long-term protection. 3. Powder coating: Powder coating involves applying a dry powder to the steel angle which is then cured at high temperatures. This creates a hard, durable, and protective layer on the surface. Powder coating provides an attractive finish and excellent resistance to corrosion, making it suitable for both indoor and outdoor applications. 4. Stainless steel: Using stainless steel angles is another method for protecting against corrosion. Stainless steel contains chromium, which forms a passive oxide layer on the surface that acts as a protective barrier against corrosion. This makes stainless steel highly resistant to rust, making it ideal for applications where corrosion is a concern. 5. Cathodic protection: Cathodic protection is a technique used to protect steel angles by making them the cathode in a corrosion cell. This is achieved by connecting the steel angle to a sacrificial anode, such as zinc or aluminum, or by using impressed current systems. By doing so, the anode corrodes instead of the steel, effectively protecting it from corrosion. It is worth noting that the selection of the appropriate method for protecting steel angles from corrosion depends on various factors such as the intended application, environmental conditions, and budget constraints. Consulting with corrosion experts and considering the specific requirements of the project is advisable to ensure the most suitable method is chosen.

- Q: Can steel angles be used in the construction of storage tanks?

- Steel angles have the potential to be utilized in the construction of storage tanks. These angles are frequently employed in the construction sector due to their robustness, longevity, and adaptability. When it comes to storage tanks, steel angles can serve as structural elements to provide the necessary support and stability for the tank's framework. They are commonly employed to establish the framework for the tank's walls, roof, and base, thereby ensuring the overall strength and stability of the tank. Furthermore, steel angles can also be used to reinforce corners and joints, thereby enhancing the structural integrity of the tank. In general, incorporating steel angles into the construction of storage tanks is a dependable and cost-efficient option.

- Q: Can steel angles be used for pipe supports?

- Indeed, steel angles are suitable for pipe supports. Owing to their robustness and ability to bear weight, steel angles present a reliable and long-lasting solution for bolstering pipes. The structural integrity of steel angles, combined with their L-shaped configuration, ensures exceptional stability and effortless attachment to walls, ceilings, or other structural components. Moreover, steel angles can be joined through welding or bolting to fashion tailor-made setups that cater to specific pipe support needs. The versatility, strength, and simplicity of installation make steel angles a favored option for pipe support across diverse industries, including construction, plumbing, and manufacturing.

Send your message to us

Equal Angle Bar, Steel Galvanized Angle Iron, Mild Steel Equal Angle

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords