Equal-Unequal Black & Galvanized Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Detailed Informaion

Name | Equal/Unequal Angle Steel Bar |

Shape | Equal/Unequal Angle |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

Specification | Weight | Specification | Weight |

Leg length*leg length*thickness |

| Leg length*leg length*thickness | (kg/m) |

(mm) | (kg/m) | (mm) |

|

25*25*3 | 1.124 | 90*90*8 | 10.946 |

25*25*4 | 1.459 | 90*90*10 | 13.476 |

30*30*3 | 1.373 | 100*100*6 | 9.366 |

30*30*4 | 1.786 | 100*100*7 | 10.83 |

40*40*3 | 1.852 | 100*100*8 | 12.276 |

40*40*4 | 2.422 | 100*100*10 | 15.12 |

40*40*5 | 2.976 | 100*100*12 | 17.898 |

45*45*3 | 2.088 | 110*110*7 | 11.928 |

45*45*4 | 2.736 | 110*110*8 | 13.532 |

45*45*5 | 3.369 | 110*110*10 | 16.69 |

50*50*3 | 2.332 | 110*110*12 | 19.782 |

50*50*4 | 3.059 | 125*125*8 | 15.504 |

50*50*5 | 3.77 | 125*125*10 | 19.133 |

50*50*6 | 4.465 | 125*125*12 | 22.696 |

63*63*5 | 4.822 | 125*125*14 | 26.193 |

63*63*6 | 5.721 | 140*140*10 | 21.488 |

63*63*8 | 7.469 | 140*140*12 | 25.522 |

70*70*5 | 5.397 | 140*140*14 | 29.49 |

70*70*6 | 6.406 | 160*160*10 | 24.729 |

70*70*7 | 7.398 | 160*160*12 | 29.391 |

70*70*8 | 8.373 | 160*160*14 | 33.987 |

75*75*5 | 5.818 | 160*160*16 | 38.518 |

75*75*6 | 6.905 | 180*180*12 | 33.159 |

75*75*7 | 7.976 | 180*180*14 | 38.383 |

75*75*8 | 9.03 | 180*180*16 | 43.542 |

75*75*10 | 11.089 | 180*180*18 | 48.634 |

80*80*6 | 7.376 | 200*200*14 | 42.894 |

80*80*7 | 8.525 | 200*200*16 | 48.68 |

80*80*8 | 9.658 | 200*200*18 | 54.401 |

80*80*10 | 11.874 | 200*200*20 | 60.056 |

90*90*6 | 8.35 | 200*200*24 | 71.168 |

90*90*7 | 9.656 |

|

|

Company Introduction

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

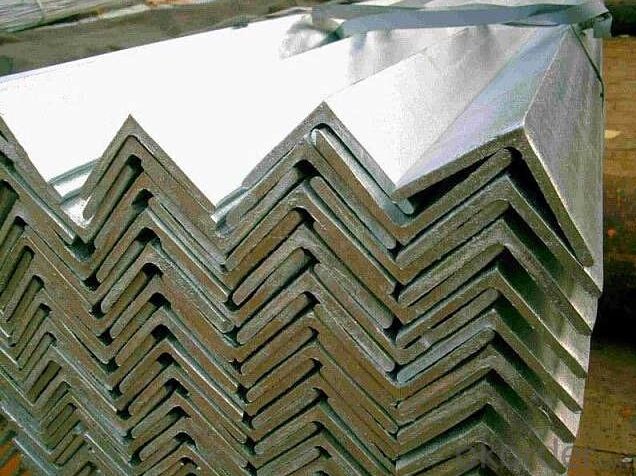

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to the marine industry?

- Special steel plays a crucial role in the marine industry by providing superior strength, durability, and corrosion resistance, which are essential qualities for various marine applications. One significant contribution of special steel to the marine industry is in the construction of ships and submarines. These vessels are subjected to harsh environmental conditions, including exposure to saltwater, extreme temperatures, and high pressures. Special steel, such as high-strength low-alloy (HSLA) steel or stainless steel, helps ensure the structural integrity of these vessels and enhances their overall performance. The steel's high strength-to-weight ratio allows for the construction of lighter yet robust hulls, enabling ships and submarines to navigate through rough seas more efficiently. Additionally, special steel is extensively used in marine equipment and components. For example, it is employed in the manufacturing of propeller shafts, rudders, and other critical parts that need to withstand the forces exerted by the water. The corrosion-resistant properties of stainless steel make it ideal for various marine fittings, such as valves, fasteners, and pipes, ensuring longevity and efficient operation in a highly corrosive marine environment. Moreover, special steel finds applications in offshore structures, including oil rigs, platforms, and wind turbines. These structures must withstand harsh conditions like strong ocean currents, heavy waves, and corrosive saltwater. Special steel grades, such as carbon-manganese steel or weathering steel, are specifically designed to provide exceptional strength and resistance against corrosion, making them suitable for offshore installations. Lastly, in the marine industry, special steel is indispensable for the fabrication of marine containers and cargo handling equipment. The steel's high tensile strength and impact resistance allow for safe transportation of goods by sea, ensuring that containers can withstand the dynamic forces during shipping and protect the cargo from water intrusion. Overall, special steel's unique properties make it an indispensable material in the marine industry. Its strength, durability, and corrosion resistance contribute significantly to the construction of ships, submarines, offshore structures, marine equipment, and cargo containers, enabling safe and efficient maritime operations.

- Q: How does special steel perform in radiation shielding applications?

- Special steel is an excellent choice for radiation shielding applications due to its high density and ability to absorb and scatter radiation effectively. Its unique composition and properties allow it to provide a strong barrier against various types of radiation, ensuring the safety of individuals and equipment in radiation-prone environments.

- Q: What are the main advantages of using special steel in the oil and gas industry?

- The main advantages of using special steel in the oil and gas industry include its high strength, corrosion resistance, and ability to withstand extreme temperatures and pressures. Special steel is specifically designed and manufactured to meet the demanding requirements of the industry, ensuring reliable performance and longevity. It also offers excellent weldability, which is crucial for constructing pipelines and equipment used in oil and gas operations. Additionally, special steel's durability and resistance to fatigue make it ideal for withstanding the harsh conditions and environments encountered in the oil and gas sector.

- Q: Can special steel be used for precision instruments?

- Yes, special steel can be used for precision instruments. Special steel, known for its high strength, durability, and resistance to corrosion, is often used in the manufacturing of precision instruments such as surgical tools, watches, measuring devices, and scientific equipment. Its unique properties allow for precise and accurate performance, making it an ideal material choice for precision instruments.

- Q: What are the properties of corrosion-resistant alloy steel?

- Corrosion-resistant alloy steel possesses properties such as high resistance to corrosion, excellent strength, durability, and the ability to withstand harsh environmental conditions. It is resistant to rust, corrosion, and oxidation, making it ideal for applications in industries such as marine, chemical, and oil and gas. The alloy steel also offers good mechanical properties, including high tensile strength and toughness, which ensures its long-term performance and reliability.

- Q: How is special steel used in the marine supply chain?

- Special steel is used extensively in the marine supply chain due to its exceptional strength, corrosion resistance, and durability. It is utilized in the construction of various marine components such as ship hulls, propeller shafts, offshore platforms, and marine equipment. Special steel ensures the structural integrity and longevity of these critical marine structures, enabling safe and efficient operations in harsh and corrosive marine environments.

- Q: How does special steel contribute to the automotive aftermarket?

- Special steel contributes to the automotive aftermarket by providing high-performance and durable components that enhance the overall performance, safety, and reliability of vehicles. Special steel, such as high-strength steel and stainless steel, is used in the manufacturing of various automotive parts, including engine components, chassis, suspension systems, and exhaust systems. These materials offer superior strength, corrosion resistance, and heat resistance, thereby ensuring longer service life and improved performance of aftermarket automotive parts. Additionally, special steel enables the development of lightweight designs, leading to fuel efficiency improvements and reduced emissions, which are crucial factors in the automotive industry.

- Q: How does special steel perform in chemical processing applications?

- Due to its outstanding performance and unique properties, special steel finds wide application in chemical processing. Its high resistance to corrosion is a key advantage in this field. Specifically designed to withstand harsh chemical environments, special steel ensures reliability and durability. Compared to other materials, special steel provides superior protection against corrosion in chemical processing applications where corrosive substances are present. It exhibits exceptional resistance to acids, alkalis, and various chemical compounds, guaranteeing the integrity and longevity of equipment and components. In addition, special steel offers excellent mechanical properties, including high strength and toughness, which are essential in chemical processing. It can endure high temperatures, pressure, and mechanical stresses commonly encountered in these environments. Its robustness and ability to maintain structural integrity under extreme conditions make it the preferred choice for critical components such as reactors, vessels, and piping systems. Special steel also contributes to the overall efficiency and safety of chemical processing operations. Its resistance to scaling and fouling reduces the risk of contamination and blockages, minimizing downtime for cleaning and maintenance. As a result, productivity and cost-effectiveness are improved. Furthermore, special steel is frequently chosen for its hygienic properties, making it suitable for use in the food and pharmaceutical industries. It is easy to clean and sanitize, ensuring the highest levels of product purity and compliance with industry regulations. In conclusion, special steel excels in chemical processing applications. Its corrosion resistance, mechanical strength, thermal stability, and hygienic properties make it an ideal choice for equipment and components, enhancing the reliability, efficiency, and safety of chemical processing operations.

- Q: How does special steel contribute to the construction equipment industry?

- Special steel contributes to the construction equipment industry by providing high strength, durability, and resistance to wear and tear. This type of steel is specifically designed to withstand harsh working conditions, such as heavy loads, extreme temperatures, and abrasive materials. Special steel components, such as gears, bearings, and cutting edges, improve the performance and lifespan of construction equipment, enabling them to operate efficiently and reliably. Additionally, special steel alloys offer flexibility in design and manufacturing, allowing for the production of lighter and more fuel-efficient machines, ultimately contributing to increased productivity and cost-effectiveness in the construction industry.

- Q: How does special steel resist corrosion?

- Special steel resists corrosion due to the presence of alloying elements, such as chromium, nickel, and molybdenum, which form a protective oxide layer on its surface. This oxide layer acts as a barrier, preventing the steel from coming into direct contact with corrosive agents, such as moisture, oxygen, and chemicals, thereby significantly reducing the chances of corrosion.

Send your message to us

Equal-Unequal Black & Galvanized Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords