High Quality for Bearing Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200Ton m.t.

- Supply Capability:

- 500Tons per day m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality for Bearing Steel

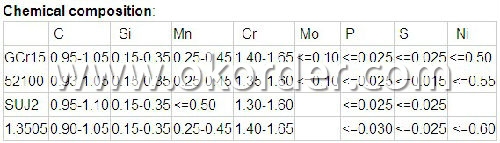

1. Grade: GCr15/SAE52100/EN31/DIN 1.3505/JIS SUJ2

2. Sizes: Diameter 80-1000mm,or as required; Length 500-6000mm,or as required;.

3. Processing: Hot- forged, EAF+LF+VD+Forged+Heat treatment (A,N,Q,T for optional)

4. Heat Treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

5. Surface requirements: Black, grinding, bright, polish

6. Features:

Stable elements, low harmful elements, high-purity steel, evenly carbides, ewer surface defects;

using with wide range of plastic processing, heat treatment with stable quality, high and

evenly hardness, good wear resistance, high strength of contact fatigue; excellent cutting and process ability.

7.

8.Payment terms: T/T or L/C at sight

Usage & Applications of High Quality for Bearing Steel

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Packaging & Delivery of High Quality for Bearing Steel

Mark: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted.

Standard seaworthy packing or as customer required

Delivery time: Within 30 days after order is confirmed.

- Q: What are the requirements for special steel used in low-temperature applications?

- To ensure optimal performance and reliability in low-temperature applications, special steel must fulfill specific criteria. These criteria primarily encompass three crucial factors: toughness, resistance to brittle fracture, and corrosion resistance. Toughness plays a paramount role in low-temperature applications as it determines a material's capacity to absorb energy and withstand cracking or fracturing. High toughness is essential in special steel designed for low-temperature environments, which is typically achieved through the addition of specific alloying elements like nickel and manganese. These elements enhance the steel's ability to endure impact loads and prevent catastrophic failures. Another vital requirement for steel used in low-temperature settings is resistance to brittle fracture. At low temperatures, steel becomes more prone to brittle fracture, which can occur suddenly without any significant deformation or warning signs. To mitigate this risk, special steel for low-temperature applications undergoes specific heat treatment processes to refine its microstructure and enhance its resistance to brittle fracture. Corrosion resistance also plays a crucial role in special steel intended for low-temperature applications. Low temperatures often lead to the formation of ice or condensation, which can introduce moisture and potentially corrosive substances to the steel's surface. Therefore, the steel must possess exceptional corrosion resistance properties to prevent degradation and maintain its structural integrity over time. This is typically achieved by incorporating corrosion-resistant elements such as chromium and molybdenum. In addition to these primary requirements, other factors like dimensional stability, weldability, and cost-effectiveness should also be taken into consideration when selecting special steel for low-temperature applications. The material should exhibit good dimensional stability to retain its shape and mechanical properties under varying temperature conditions. It should also be easily weldable to facilitate construction and maintenance processes. Furthermore, the chosen steel should strike a balance between performance and the overall project budget, ensuring cost-effectiveness. In conclusion, special steel used in low-temperature applications must possess high toughness, resistance to brittle fracture, and corrosion resistance. Meeting these requirements guarantees the steel's reliability and longevity in demanding low-temperature environments, enabling safe and efficient operations in various industries such as cryogenic storage, oil and gas exploration, and transportation.

- Q: What are the emerging trends in the special steel industry?

- Some of the emerging trends in the special steel industry include the growing demand for advanced high-strength steels (AHSS) in automotive applications due to their lightweight and high performance properties. Additionally, there is an increasing focus on sustainability and eco-friendly manufacturing processes, leading to the development of cleaner production methods and the use of recycled materials. Furthermore, advancements in technology and innovation are driving the adoption of specialty steels in sectors such as aerospace, energy, and construction.

- Q: What are the main applications of special steel in the packaging machinery?

- Special steel is widely used in packaging machinery for various applications, including the production of durable and corrosion-resistant parts such as blades, cutting tools, and machine components. The high strength and hardness of special steel allow for efficient and precise cutting, shaping, and sealing processes, ensuring the quality and reliability of packaging operations. Additionally, special steel's resistance to wear and tear enhances the longevity of packaging machinery, reducing maintenance costs and downtime.

- Q: What are the applications of special steel in the nuclear industry?

- Special steel has various applications in the nuclear industry due to its unique properties. It is commonly used in the construction of nuclear reactors, fuel assemblies, and containment vessels. Special steel's high strength, corrosion resistance, and ability to withstand high temperatures make it ideal for these applications, ensuring the safety and efficiency of nuclear power plants.

- Q: What are the requirements for special steel used in cryogenic applications?

- Special steel used in cryogenic applications must meet several requirements to ensure its performance and reliability in extreme low-temperature environments. Firstly, the steel should have excellent low-temperature toughness to withstand the extreme cold. This means that it should be able to resist brittle fracture and maintain its mechanical properties even at cryogenic temperatures. The steel should have a high toughness and ductility to absorb impact and prevent cracking. Secondly, the steel must have a low coefficient of thermal expansion. This is important because cryogenic applications involve significant temperature changes, and a high coefficient of thermal expansion can lead to dimensional instability and stress within the material. A low coefficient of thermal expansion helps to minimize these effects and maintain dimensional stability. Thirdly, the steel should have a low thermal conductivity. Cryogenic applications often involve the transfer or storage of extremely cold substances, and a low thermal conductivity helps to prevent heat transfer and maintain the desired temperature. This is particularly important for applications where temperature control is critical, such as in the storage of liquefied gases. Additionally, the steel should have good corrosion resistance. Cryogenic environments can be highly corrosive, and the steel needs to be able to withstand the effects of any corrosive substances that may be present. This is particularly important for applications involving the storage or transportation of cryogenic liquids or gases. Finally, the steel should have good weldability. In many cryogenic applications, welding is required to join different components or sections of the steel. Therefore, the steel must have good weldability to ensure strong and reliable joints. In summary, the requirements for special steel used in cryogenic applications include excellent low-temperature toughness, low coefficient of thermal expansion, low thermal conductivity, good corrosion resistance, and good weldability. Meeting these requirements ensures that the steel can withstand the extreme cold and harsh conditions of cryogenic environments while maintaining its structural integrity and performance.

- Q: What are the main characteristics of heat-resistant steel?

- Heat-resistant steel, known as high-temperature steel as well, is an alloy with specific properties that enable it to endure extreme temperatures without sacrificing its mechanical strength and integrity. The primary features of heat-resistant steel are as follows: 1. Thermal fatigue resistance: Heat-resistant steel is designed to endure cyclic heating and cooling without developing cracks or fractures. This characteristic allows it to maintain its structural integrity, even in environments with rapid temperature fluctuations. 2. Exceptional creep resistance: Creep refers to the gradual deformation that occurs in a material when exposed to high temperatures over an extended period. Heat-resistant steel exhibits exceptional resistance to creep, ensuring that it retains its shape and strength even under prolonged heat exposure. 3. Preservation of mechanical properties at elevated temperatures: Unlike regular steel, which experiences a significant reduction in strength and hardness at high temperatures, heat-resistant steel retains its mechanical properties even under extreme conditions. This property makes it suitable for applications in industries such as aerospace, power generation, and oil and gas. 4. Resistance to oxidation and corrosion: Heat-resistant steel possesses a high resistance to oxidation and corrosion at elevated temperatures. It forms a protective oxide layer on its surface, preventing the underlying material from being attacked by oxygen or other corrosive elements. This property enhances the longevity and reliability of components made from heat-resistant steel. 5. Excellent thermal conductivity: Heat-resistant steel exhibits outstanding thermal conductivity, allowing it to efficiently transfer heat away from its surface. This feature proves particularly beneficial in applications where heat dissipation is crucial, such as in heat exchangers and furnace components. 6. Minimal thermal expansion: Heat-resistant steel has a relatively low coefficient of thermal expansion, meaning it expands and contracts minimally when subjected to temperature changes. This characteristic ensures dimensional stability and reduces the risk of warping or distortion under thermal stress. In summary, the main characteristics of heat-resistant steel make it an ideal material for applications that involve exposure to high temperatures, such as furnace components, exhaust systems, gas turbines, and heat exchangers. Its ability to endure extreme heat while maintaining its structural integrity and mechanical properties make it a critical material in industries where temperature resistance is of utmost importance.

- Q: What are the properties of electrical resistance steel?

- Electrical resistance steel is characterized by its high resistivity, which means it offers high resistance to the flow of electric current. It also exhibits good electrical conductivity, ensuring efficient transmission of electric power. Additionally, electrical resistance steel typically has a low temperature coefficient of resistance, meaning its resistance does not change significantly with temperature fluctuations. These properties make it suitable for various applications, such as in electrical resistors, heating elements, and electrical wiring where controlled resistance and durability are required.

- Q: What are the different methods of improving the machinability of special steel?

- There are several methods available for improving the machinability of special steel. One approach is to modify the steel composition by adding elements such as sulfur, lead, or selenium, which can help break the chips during the machining process. Another method involves using coatings or surface treatments on the steel to reduce friction and heat generation during machining. Additionally, optimizing the cutting parameters, such as speed, feed rate, and cutting tool geometry, can also enhance machinability. Lastly, post-machining processes like stress relieving or heat treatment can be employed to improve the overall machinability of the special steel.

- Q: What are the main factors affecting the fatigue strength of special steel?

- The main factors affecting the fatigue strength of special steel include the material's microstructure, surface condition, heat treatment, and loading conditions. Additionally, factors such as environmental conditions, stress concentration, and the presence of defects or imperfections can also influence the fatigue strength of special steel.

- Q: Can special steel be used in the manufacturing of consumer goods?

- Yes, special steel can be used in the manufacturing of consumer goods. Special steel refers to a specific type of steel that has been engineered to possess unique properties, such as increased strength, corrosion resistance, heat resistance, or wear resistance. These enhanced properties make it suitable for a wide range of applications, including consumer goods. Consumer goods encompass a diverse range of products, such as kitchen appliances, electronics, automobiles, tools, and furniture. Special steel can be utilized in various components and parts of these goods to enhance their performance and durability. For example, in kitchen appliances, special steel can be used to manufacture blades, heating elements, or cooking surfaces, providing improved cutting efficiency, heat distribution, and resistance to corrosion. In electronics, special steel can be used to manufacture casings, connectors, or springs, ensuring durability, conductivity, and resistance to temperature fluctuations. Furthermore, special steel can also be used in manufacturing consumer goods that require high precision and reliability. For instance, in automotive manufacturing, special steel can be used for engine components, chassis, or safety features, providing enhanced strength, impact resistance, and structural integrity. Similarly, in the production of tools and equipment, special steel can be used to manufacture drill bits, cutting tools, or machine components, ensuring longevity, precision, and performance. Overall, special steel offers distinct advantages over conventional steel in terms of its unique properties, making it a suitable material choice for manufacturing consumer goods. Its enhanced strength, corrosion resistance, heat resistance, or wear resistance characteristics can significantly improve the performance, durability, and reliability of consumer products, meeting the demands and expectations of consumers.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1990 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

High Quality for Bearing Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200Ton m.t.

- Supply Capability:

- 500Tons per day m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords