AISI 52100 Bearing Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of AISI 52100 Bearing Steel

1. Standard:

CHINA | ISO | U.S.A. | GERMANY | JAPAN | SWENDEN | FRANCE |

Gcr15 | 683/XVII | 52100(AISI) | 100Cr6(DIN) | SUJ2(JIS) | SKF3 | 100C6(NF) |

2. Dimensions: Diameter 80-1000mm,or as required; Length 500-6000mm,or as required;

3. Processing conditions:

Annealing: Heating to 790-810°C, furnace cool to 650°C, then cool in air |

Normalized: Heating to 900-920°C, cool in air |

High Temperature Tempered: Heating to 650-800°C, cool in air |

Quenched: Heating to 860°C, oil quenched |

Low Temperature Tempered: Heating to 150-170°C, cool in air |

4. Characters:

1) Comprehensive properties

2) Good performance in cutting and processing after spheroids annealing

3) High hardness and homogenization after quenching and tempering

4) High abrasive resistance and fatigue resistance

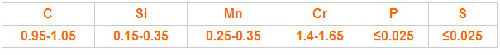

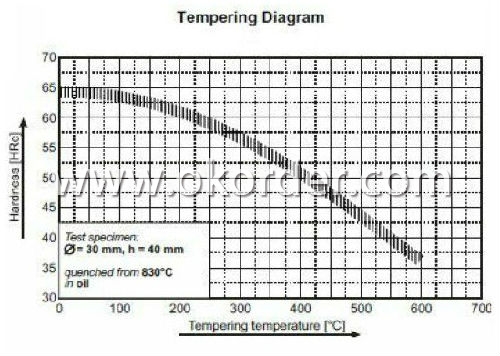

5. Chemical Composition

6.Tempering Diagram

.

7. Payment terms: T/T or L/C at sight

Usage & Applications of AISI 52100 Bearing Steel

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Packaging & Delivery of AISI 52100 Bearing Steel

Mark: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm),

and the manufacturer LOGO and weight (kg) is painted.

Standard seaworthy packing or as customer required

Delivery time: Within 30 days after order is confirmed.

- Q: How does special steel contribute to reducing material waste?

- Special steel contributes to reducing material waste through its superior properties and durability. Unlike traditional steel, special steel is designed to have enhanced strength, corrosion resistance, and wear resistance. These properties allow for the production of thinner and lighter components without compromising their functionality, leading to reduced material consumption. Additionally, the longevity and resistance to wear of special steel products result in longer service life, minimizing the need for frequent replacements and further reducing material waste.

- Q: What are the non-destructive testing methods used for special steel?

- Some of the non-destructive testing methods used for special steel include ultrasonic testing, magnetic particle testing, liquid penetrant testing, and radiographic testing. These methods allow for the detection of defects, cracks, or other imperfections in the steel without causing any damage to the material itself.

- Q: What are the magnetic properties of special steel?

- Special steel can exhibit a range of magnetic properties, depending on its composition and treatment. Some special steels, such as austenitic stainless steel, are non-magnetic due to their high nickel content. On the other hand, certain types of special steel, like ferritic or martensitic stainless steel, can be magnetic. Additionally, some special steels can be made magnetic through processes like heat treatment or cold working. Therefore, the magnetic properties of special steel can vary and are influenced by several factors.

- Q: How is structural steel used in building construction?

- Structural steel is extensively used in building construction due to its high strength and versatility. It serves as the primary framework for buildings, providing support and stability. The steel beams and columns are used to create the skeleton of the structure, spanning large distances and allowing for open floor plans. Additionally, steel is used for various other elements such as stairs, handrails, and roof trusses. Its durability, fire resistance, and ability to withstand extreme weather conditions make it an ideal material for constructing high-rise buildings, industrial facilities, and bridges.

- Q: Can special steel be used for precision instruments?

- Yes, special steel can be used for precision instruments. Special steel, such as tool steel or stainless steel, offers excellent hardness, strength, and corrosion resistance, making it ideal for precision instruments that require high accuracy and durability.

- Q: What are the main industries that use special steel?

- Special steel is widely used in several industries due to its unique properties and characteristics. Some of the main industries that heavily rely on special steel include: 1. Automotive Industry: Special steel is extensively used in the manufacturing of various automotive components such as engine parts, transmission gears, suspension systems, and exhaust systems. Its high strength, durability, and resistance to wear and corrosion make it ideal for these applications. 2. Aerospace Industry: Special steel is crucial for the aerospace industry as it is used in the production of aircraft components including turbine blades, landing gears, and structural parts. The high temperature resistance, strength, and lightweight properties of special steel are vital for ensuring the safety and efficiency of aerospace systems. 3. Energy and Power Generation: Special steel finds applications in the energy sector, particularly in power plants and nuclear facilities. It is used for the construction of turbines, generators, and heat exchangers, where its high temperature resistance and exceptional strength are vital for efficient energy production. 4. Oil and Gas Industry: Special steel is extensively used in the oil and gas sector for drilling equipment, pipelines, valves, and other components. The corrosion resistance, high strength, and ability to withstand extreme conditions make special steel a preferred choice in this industry. 5. Construction and Infrastructure: Special steel is utilized in the construction industry for various purposes such as building structures, bridges, and high-rise buildings. Its high tensile strength, durability, and resistance to impact and corrosion ensure the integrity and longevity of these structures. 6. Tool and Die Making: Special steel is widely used in the manufacturing of tools and dies for various industrial processes. Its hardness, toughness, and wear resistance make it ideal for applications such as cutting, drilling, and shaping metals. 7. Defense and Military: Special steel plays a crucial role in the defense and military sector, where it is used for the production of armored vehicles, weapons, and other military equipment. Its ability to withstand high impacts, resist ballistic penetration, and maintain structural integrity under extreme conditions is vital for ensuring the safety and effectiveness of military operations. In summary, the main industries that heavily rely on special steel include automotive, aerospace, energy and power generation, oil and gas, construction and infrastructure, tool and die making, and defense and military. These industries benefit from the unique properties of special steel, such as high strength, durability, resistance to wear and corrosion, and the ability to withstand extreme conditions.

- Q: What are the applications of special steel in the renewable energy sector?

- Special steel plays a crucial role in the renewable energy sector by enabling the development and advancement of various technologies. One of the key applications of special steel in this sector is in the manufacturing of wind turbines. Wind turbine components such as towers, generator frames, rotor hubs, and bearings require high-strength, corrosion-resistant steel to withstand the harsh operating conditions, including strong winds and exposure to moisture. Special steel provides the necessary properties to ensure the longevity and reliability of wind turbines, thus contributing to the growth of wind energy. Moreover, special steel is extensively used in the construction of solar power plants. Solar panel frames, mounting structures, and support systems require steel with excellent structural integrity, durability, and resistance to environmental degradation. Special steel provides these qualities, ensuring the stability and performance of solar installations. In addition, special steel finds applications in the production of components for hydroelectric power plants. The construction of turbines, penstocks, and other hydraulic equipment demands steel with high tensile strength and resistance to corrosion caused by water and sediments. Special steel alloys possess these characteristics, making them ideal for hydroelectric power generation. Furthermore, special steel is utilized in the manufacturing of energy storage systems, such as batteries and fuel cells. These systems often require steel with exceptional conductivity, corrosion resistance, and mechanical strength to ensure efficient and reliable energy storage. Special steel alloys can meet these requirements, making them suitable for use in renewable energy storage technologies. In summary, special steel plays a vital role in the renewable energy sector by offering the necessary properties for the manufacturing of wind turbines, solar power plants, hydroelectric power plants, and energy storage systems. Its high-strength, corrosion-resistant, and durable characteristics enable the development of efficient and reliable renewable energy technologies, contributing to the sustainable energy transition.

- Q: How is special steel used in the production of turbine shafts?

- Special steel is used in the production of turbine shafts due to its high strength, durability, and resistance to corrosion and fatigue. The unique properties of special steel make it ideal for withstanding the extreme conditions and loads experienced by turbine shafts during operation, ensuring efficient and reliable power generation.

- Q: What are the main characteristics of tool steel?

- Tool steel is a type of steel that is specifically designed for the production of tools, such as drills, dies, and cutting instruments. It possesses several key characteristics that make it suitable for these applications. Firstly, tool steel is known for its exceptional hardness. It has a high carbon content, typically ranging from 0.5% to 1.5%, which contributes to its hardness. This hardness allows tool steel to resist wear and abrasion, making it ideal for cutting and shaping materials. Another important characteristic of tool steel is its high toughness. Tool steel is able to withstand high impact and shock loads without fracturing or breaking. This toughness is crucial in tooling applications where tools are subjected to heavy loads and forces. Tool steel also exhibits excellent heat resistance. It has a high melting point, allowing it to maintain its strength and hardness even at elevated temperatures. This heat resistance is crucial in applications where tools are exposed to high temperatures during cutting or shaping processes. In addition to these characteristics, tool steel possesses good dimensional stability and machinability. It has low distortion and shrinkage during heat treatment, ensuring that the tool maintains its shape and size. Tool steel is also easily machinable, allowing for the production of intricate shapes and designs. Overall, the main characteristics of tool steel include high hardness, toughness, heat resistance, dimensional stability, and machinability. These properties make tool steel an ideal material for the production of tools that require high strength, durability, and performance.

- Q: How are magnesium alloys used in lightweight structures?

- Magnesium alloys are used in lightweight structures due to their exceptional strength-to-weight ratio. These alloys offer high strength and stiffness while being significantly lighter than other metals like steel or aluminum. This makes them ideal for applications in sectors such as aerospace, automotive, and sports equipment, where weight reduction is crucial without compromising structural integrity. Additionally, magnesium alloys possess good vibration damping properties, corrosion resistance, and excellent machinability, making them even more advantageous for lightweight structure design.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1990 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

AISI 52100 Bearing Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords