20Cr Steel Round Bar SAE520 Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

20Cr Steel Round Bar SAE520 Steel Round Bar

Product Description:

1.Standard:40Cr,20Cr, 40CrMo4,SCM440,AISI4140, etc.

2.Diameter:25mm-450mm

3.Length:5.8/6m-12m or as required

4.Application:re-manufacture, structural steel etc.

5.Certificates:ISO9001:2008,ISO14001:2004,OHSAS18001

6.Packing: In bundles,Standard export sea-worthy packing or as customer's requirement

7.Shipment: by bulk or by container

8.Quality Contation

Both end of each bar must be cut.

Ladle furnanced and vacuum de-gassed

Show heat No. on each bar

Surface condition the surface of the hot rolled square bar shall befree cracks, scar and wrinkles that affect the use of the

billets. In case there is the above-mentioned defect, it shall be remove.

The mill test certificate shall show the chemical composition, and it is guaranteed that the chemical composition shall be

within the limit stipulated in the contract.

Chemical composition:

Grade | C | Si | Mn | Cr |

20Cr | 0.18-0.24 | 0.17-0.37 | 0.5-0.8 | 0.7-0.9 |

Specification:

OD | Length | Material | Standard | Technique |

16-260mm | 6-12m or aques per request | 20# | GB ASTM DIN | Hot rolled |

16-350mm | 45# | |||

200-500mm | 45# | Forged | ||

20-250mm | 20Cr,40Cr,20-42CrMo | Hot rolled | ||

50-300mm | GCr15 |

Application:

Hot rolled alloy structure steel round bar are widely used in machinery making, autombile making, railway, mine machinery, petoleum machinry, agricultural machinery and civil archtectue such as all kinds of shafts, screws, connecting rods, hardware tools, gears, standard parts, spanners fasteners, structural parts for automobile and agricultural machinery, outer and iner sleeves, rollers and balls for bearing making.

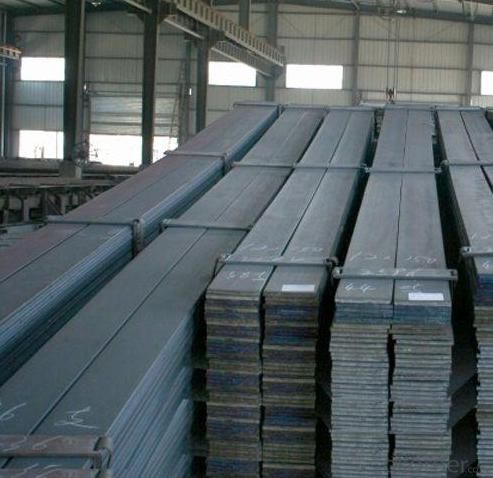

Product Show:

- Q: What are the main applications of special steel in the marine sector?

- Special steel is widely used in the marine sector for various applications. Some of the main applications include the construction of ship hulls, offshore platforms, and marine structures. Special steel's high strength, corrosion resistance, and durability make it suitable for withstanding harsh marine environments. Additionally, special steel is used in propeller shafts, rudders, and other critical components, ensuring efficient and reliable performance of marine vessels.

- Q: How does special steel perform in cryogenic fatigue resistance?

- Special steel generally performs well in cryogenic fatigue resistance. The unique composition and heat treatment processes used in manufacturing special steel result in improved strength, toughness, and resistance to cracking at low temperatures. This makes it highly suitable for applications in cryogenic environments where materials are subjected to extreme cold temperatures and cyclic loading.

- Q: What are the properties of martensitic steel?

- Martensitic steel is characterized by its high strength, hardness, and wear resistance. It possesses a unique microstructure consisting of a body-centered tetragonal crystal lattice, resulting in its distinctive properties. Martensitic steel can be hardened through quenching and tempering processes, allowing it to maintain its strength even at elevated temperatures. Additionally, it exhibits good corrosion resistance and is commonly used in applications that require high toughness and durability, such as in cutting tools, surgical instruments, and automotive components.

- Q: What are the main advantages of using special steel in the oil and gas industry?

- The main advantages of using special steel in the oil and gas industry are its high strength and resistance to corrosion, which enhances the durability and longevity of equipment and pipelines. Special steel also has excellent heat resistance, allowing it to withstand high temperatures and pressures commonly found in oil and gas operations. Additionally, special steel offers superior weldability and machinability, making it easier to fabricate and install in complex infrastructure.

- Q: How does special steel contribute to reducing product waste?

- Special steel contributes to reducing product waste by offering superior strength, durability, and corrosion resistance. This allows manufacturers to produce longer-lasting and more reliable products, minimizing the need for frequent replacements. Additionally, special steel's high precision and customization capabilities enable the creation of components with tight tolerances, reducing the risk of assembly errors and subsequent product failures. Consequently, special steel helps optimize product performance and longevity, thereby reducing waste generated from premature product disposal.

- Q: How does special steel perform in additive manufacturing applications?

- Special steel performs well in additive manufacturing applications due to its high strength, durability, and resistance to wear and corrosion. The unique properties of special steel, such as its ability to withstand high temperatures and extreme environments, make it an ideal material for 3D printing processes. Additionally, the flexibility and customization offered by additive manufacturing allows for the creation of complex geometries and intricate designs, further enhancing the performance of special steel in various applications.

- Q: How does special steel perform in hot forging processes?

- Special steel is specifically designed to withstand high temperatures and perform well in hot forging processes. When exposed to extreme heat, special steel maintains its strength and hardness, making it ideal for use in hot forging applications. One of the main advantages of special steel in hot forging is its excellent heat resistance. It can withstand high temperatures without losing its structural integrity, ensuring that it maintains its desired properties throughout the forging process. This allows for the production of forged components with consistent quality and dimensional accuracy. Furthermore, special steel exhibits good thermal conductivity, which helps to distribute heat evenly during the forging process. This enables efficient heating and reduces the risk of localized overheating or cold spots. The even distribution of heat also contributes to uniform grain structure, which enhances the overall strength and mechanical properties of the forged parts. In addition, special steel possesses excellent wear resistance and toughness, even at elevated temperatures. This ensures that the steel can withstand the significant forces and pressures involved in the hot forging process without easily deforming or failing. The combination of high strength, wear resistance, and toughness allows for the production of forged components that can withstand heavy loads and harsh operating conditions. Moreover, special steel can be easily machined and formed, allowing for intricate designs and complex shapes to be forged. This versatility makes it suitable for a wide range of hot forging applications, including automotive parts, industrial machinery components, and aerospace components. In summary, special steel performs exceptionally well in hot forging processes. Its heat resistance, thermal conductivity, wear resistance, toughness, and machinability make it an ideal material choice for producing high-quality, durable, and complex forged components.

- Q: What are the properties of silicon steel?

- Silicon steel, also known as electrical steel, possesses several notable properties. It has a high magnetic permeability, which enables it to efficiently conduct and generate electric currents. Additionally, silicon steel exhibits low core losses, making it ideal for use in electrical transformers and motors where energy efficiency is crucial. Furthermore, it has a high resistivity, allowing it to minimize eddy current losses. Overall, silicon steel's properties make it a valuable material in various electrical applications.

- Q: How does nitriding steel improve hardness and wear resistance?

- Nitriding steel improves hardness and wear resistance by introducing nitrogen into the steel's surface through a heat treatment process. This forms nitrides, which are hard compounds that increase the material's surface hardness. Additionally, the nitrogen atoms create compressive stresses within the structure, enhancing the material's resistance to wear and fatigue.

- Q: What are the common alloys used in special steel?

- Some common alloys used in special steel include stainless steel (which contains chromium and often nickel), tool steel (which contains tungsten, vanadium, and sometimes cobalt), and high-speed steel (which contains tungsten, molybdenum, and sometimes cobalt).

Send your message to us

20Cr Steel Round Bar SAE520 Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords