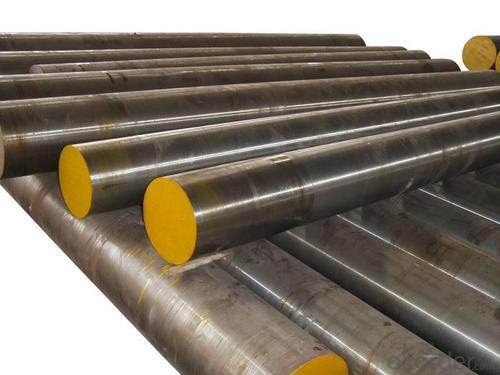

Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction:

-Material: 60Si2CrA

-Standard: GB/T 1222-1984

-Type: Spring Steel

Corresponding Steel Grade for Reference:

CHN, GB | JPN, JIS | GER, DIN | GBR, BS |

60Si2CrA | SWOSC-V | 67SiCr5 | 685H57 |

USA, AISI/SAE/ASTM | ISO | ||

9254 | 55SiCr63 |

Chemical Composition:

C | Si | Mn | S |

0.52~0.60 | 1.5~2.00 | 0.60~0.90 | ≤0.035 |

P | Cr | Ni | Cu |

≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 |

Mechanical Properties:

-Tensile Strength σb (MPa): ≥1274(130)

-Yield Strength σs (MPa): ≥1176(120)

-Elongation δ10(%): ≥6

-Percentage reduction of area: ψ (%): ≥30

-Hardness:

1, Hot rolled, ≤302HB

2, Cold drawn + Heat treatment: ≤321HB

-Norm of heat treatment: quenching 870℃±20℃

-Micro structure: Tempered troostite.

Usage/Applications of Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction:

-Compared with Si-Mn spring steel under the similar condition of plasticity, 60Si2CrA have higher tensile strength, yield strength and hardenability.

-60Si2CrA is applied for producing springs with working temperature below 300~500℃. This type of spring can bear high stress, for example, governor spring, turbine steam seal spring, etc…

Packaging & Delivery of Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction:

-Packing Detail:

1, The products can be packed in bundles by steel wires.

2, The weight of each bundle no exceed normally 3 tons

-Marks: there are two types of marks. One is tag mark, for showing customers the specifications of products, company name and logo and other information required by customers. Other one is color marks. They are used to make the products more evident so that it’s easy for customers to distinguish them from other products at destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products are usually transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Terms of payment: T.T. or L/C at sight.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the most common alloys used in special steel?

- The most common alloys used in special steel include stainless steel, tool steel, and high-speed steel.

- Q: How does special steel contribute to improving product efficiency?

- Special steel contributes to improving product efficiency in several ways. Firstly, special steel is known for its high strength and durability, allowing manufacturers to design products that can withstand heavy loads and harsh conditions without compromising on performance. This enables the creation of more efficient and reliable products, as they can operate at optimal levels for longer periods. Additionally, special steel offers excellent corrosion resistance, which is crucial for products exposed to moisture, chemicals, or extreme temperatures. By using special steel in the manufacturing process, products can be protected from rust and other forms of degradation, ensuring their longevity and reducing the need for frequent maintenance or replacement. Furthermore, special steel often possesses unique properties such as heat resistance, electrical conductivity, or magnetic characteristics, which can be leveraged to enhance the efficiency of specific products. For example, in the automotive industry, special steel is used to make lightweight yet robust components, improving fuel efficiency and reducing emissions. Overall, special steel's exceptional strength, durability, corrosion resistance, and specialized properties enable manufacturers to create more efficient and reliable products, enhancing their performance, longevity, and sustainability.

- Q: Can special steel be used for making automotive engine components?

- Yes, special steel can be used for making automotive engine components. This type of steel offers enhanced strength, durability, and heat resistance, making it suitable for critical engine parts such as crankshafts, connecting rods, valves, and camshafts. Special steel helps improve engine performance, efficiency, and longevity, making it a preferred choice in the automotive industry.

- Q: How does special steel perform in high-pressure applications?

- High-pressure applications benefit greatly from the exceptional performance of special steel. This steel is specifically designed to endure extreme pressure conditions, making it the perfect choice for industries that require reliable and durable materials for their operations. One of the main advantages of special steel is its high tensile strength, which allows it to handle immense pressure without deforming or failing. This strength is achieved through the use of alloying elements and heat treatment processes that enhance the steel's structural integrity. As a result, special steel can withstand the intense forces exerted on it in high-pressure environments, ensuring the safety and efficiency of the equipment or structures in which it is used. Furthermore, special steel shows excellent resistance to corrosion and oxidation, further enhancing its suitability for high-pressure applications. This resistance helps maintain the steel's structural integrity, preventing any weakening or degradation that could compromise its performance under pressure. Additionally, special steel's resistance to corrosion ensures that it can endure harsh environments, such as those found in the oil and gas extraction, chemical processing, or power generation industries. Another advantage of special steel in high-pressure applications is its ability to retain its mechanical properties even at elevated temperatures. This property is crucial in industries where high temperatures are involved, such as aerospace, nuclear power, or steam generation. The steel's high-temperature strength and stability enable it to withstand the combination of high pressure and elevated temperatures, ensuring reliable performance and long-term durability. To summarize, special steel is an outstanding choice for high-pressure applications due to its high tensile strength, resistance to corrosion and oxidation, as well as its ability to maintain its mechanical properties at elevated temperatures. Its exceptional performance in these demanding conditions makes it a reliable and durable material for industries that operate in high-pressure environments.

- Q: Can special steel be used in the appliance manufacturing industry?

- Yes, special steel can be used in the appliance manufacturing industry. Special steels, such as stainless steel or high-strength steel, offer various advantages such as corrosion resistance, durability, and enhanced mechanical properties. These qualities make them suitable for manufacturing appliances that require high performance, such as refrigerators, ovens, or washing machines. Additionally, special steels can be customized to meet specific design requirements and can contribute to the overall aesthetic appeal of the appliances.

- Q: Can special steel be used in the production of jewelry?

- Yes, special steel can be used in the production of jewelry. While precious metals like gold, silver, and platinum are commonly used in jewelry making, there is also a growing trend towards using unconventional materials such as special steel. Special steel, with its unique properties like durability, strength, and corrosion resistance, can be crafted into beautiful and intricate designs that cater to a more contemporary and edgy aesthetic. Additionally, special steel jewelry is often more affordable than traditional precious metal jewelry, making it a popular choice for those seeking a unique and budget-friendly option. However, it is important to note that special steel jewelry requires proper care and maintenance to prevent tarnishing and scratching.

- Q: How does special steel perform in terms of wear resistance?

- Special steel is known for its exceptional wear resistance. Due to its unique composition and heat treatment, it exhibits a higher level of hardness and toughness compared to regular steel. This enables it to withstand abrasion, impact, and other forms of wear, making it highly suitable for applications where durability and longevity are crucial, such as in industrial machinery, cutting tools, and automotive components.

- Q: What is the role of heat treatment in special steel?

- Heat treatment plays a crucial role in enhancing the properties and performance of special steel. Special steel refers to alloys that are specifically designed to have unique characteristics, such as high strength, corrosion resistance, or heat resistance. Heat treatment involves subjecting the steel to controlled heating and cooling processes to alter its microstructure, resulting in desired properties. One of the key roles of heat treatment in special steel is to improve its mechanical properties. By carefully controlling the heating temperature and cooling rate, the steel's hardness, strength, and toughness can be enhanced. For example, through processes like quenching and tempering, special steel can be made significantly stronger and more resistant to wear and fatigue. This makes it suitable for applications where high strength and durability are required, such as in the construction of machinery, tools, or aerospace components. Heat treatment also helps to optimize the steel's resistance to corrosion. Special steel is often used in environments where it is exposed to harsh conditions, such as corrosive chemicals or high temperatures. By subjecting the steel to specific heat treatment processes, like annealing or precipitation hardening, the steel can develop a more stable microstructure that improves its resistance to corrosion and oxidation. This ensures that the special steel maintains its integrity and performance even in challenging environments. Furthermore, heat treatment can modify the steel's heat resistance properties. Special steel is frequently used in applications where it is exposed to high temperatures, such as in the manufacturing of turbines or exhaust systems. Through heat treatment techniques like normalization or hardening, the steel can be made more resistant to deformation, cracking, or softening at elevated temperatures. This enables the special steel to retain its strength and structural integrity even under extreme heat conditions. In summary, heat treatment plays a crucial role in optimizing the mechanical, corrosion resistance, and heat resistance properties of special steel. By carefully manipulating the steel's microstructure through controlled heating and cooling processes, heat treatment enhances the steel's strength, durability, and performance, making it suitable for a wide range of demanding applications.

- Q: Is special steel recyclable?

- Yes, special steel is recyclable.

- Q: How is special steel used in the construction industry?

- Special steel is used in the construction industry for various applications due to its exceptional strength, durability, and resistance to corrosion. It is commonly used for manufacturing structural components, such as beams, columns, and girders, that require high load-bearing capacities. Special steel is also utilized in the construction of bridges, towers, and high-rise buildings to ensure structural integrity and safety. Additionally, it finds application in reinforcing concrete structures, creating strong and long-lasting foundations. Overall, special steel plays a crucial role in enhancing the strength and stability of construction projects.

Send your message to us

Hot Rolled Spring Steel Bar 60Si2CrA with High Quality for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords