All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

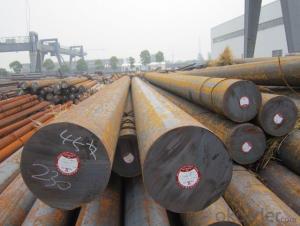

- - Special Steel

- - Steel Sheets

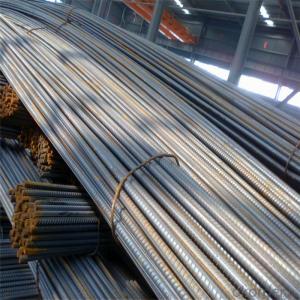

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does special steel enhance the longevity of power plants and turbines?

Special steel enhances the longevity of power plants and turbines by providing increased resistance to corrosion, high temperatures, and pressure. This enables the components made from special steel to withstand harsh operating conditions and reduces the risk of failure or breakdown. Additionally, special steel's superior strength and durability allow for longer service life, reducing the need for frequent maintenance and replacements, ultimately prolonging the overall lifespan of power plants and turbines.

How is high-speed steel tailored for cutting and machining applications?

High-speed steel is tailored for cutting and machining applications through a combination of its composition and heat treatment. It contains a higher percentage of alloying elements, such as tungsten, molybdenum, and chromium, which give it enhanced hardness, wear resistance, and heat resistance. Additionally, high-speed steel undergoes a specialized heat treatment process called quenching and tempering, which further improves its toughness and ability to withstand high temperatures. This tailored design allows high-speed steel to maintain its cutting edge sharpness, withstand high cutting speeds, and resist deformation or failure, making it highly suitable for various cutting and machining tasks.

Describe the impact of sulfur on the machinability of special steel.

Sulfur can have both positive and negative impacts on the machinability of special steel. On one hand, sulfur acts as a lubricant during the machining process, reducing friction and heat generation. This can improve tool life and surface finish, making machining operations easier and more efficient. On the other hand, excessive sulfur content can lead to the formation of brittle sulfides, which can cause tool wear and surface defects. Therefore, it is crucial to carefully control the sulfur content in special steel to optimize machinability and achieve desired machining results.

Wholesale Special Steel from supplier in Iceland

With our specialized knowledge and expertise in the Special Steel industry, we are confident in our ability to meet the unique needs and demands of the market in Iceland. We understand the importance of providing top-quality products and services to ensure the success of your projects.

Our sales team is dedicated to offering personalized assistance and support throughout the procurement process. Whether you require a single product or a complete package of Special Steel products, we can provide competitive pricing and efficient delivery to meet your deadlines.

In addition to our sales services, we also offer comprehensive technical support. Our team of experts can provide guidance and advice on the selection and application of Special Steel products, ensuring optimal performance and durability for your projects. We are committed to delivering the highest level of customer satisfaction through our reliable and professional services.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to offer a wide range of Special Steel products, including but not limited to stainless steel, tool steel, alloy steel, and carbon steel. We continuously update our product portfolio to stay abreast of the latest industry trends and advancements.

At our core, we prioritize building long-term relationships with our customers. We believe in open communication, transparency, and trust, and strive to exceed your expectations at every step. Our team is dedicated to understanding your specific requirements and providing tailored solutions that meet your unique needs.

Partner with us for all your Special Steel requirements in Iceland, and let us contribute to the success of your projects. Contact us today for a comprehensive consultation and quotation.

Our sales team is dedicated to offering personalized assistance and support throughout the procurement process. Whether you require a single product or a complete package of Special Steel products, we can provide competitive pricing and efficient delivery to meet your deadlines.

In addition to our sales services, we also offer comprehensive technical support. Our team of experts can provide guidance and advice on the selection and application of Special Steel products, ensuring optimal performance and durability for your projects. We are committed to delivering the highest level of customer satisfaction through our reliable and professional services.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to offer a wide range of Special Steel products, including but not limited to stainless steel, tool steel, alloy steel, and carbon steel. We continuously update our product portfolio to stay abreast of the latest industry trends and advancements.

At our core, we prioritize building long-term relationships with our customers. We believe in open communication, transparency, and trust, and strive to exceed your expectations at every step. Our team is dedicated to understanding your specific requirements and providing tailored solutions that meet your unique needs.

Partner with us for all your Special Steel requirements in Iceland, and let us contribute to the success of your projects. Contact us today for a comprehensive consultation and quotation.