All Categories

- - Steel Wire Rod

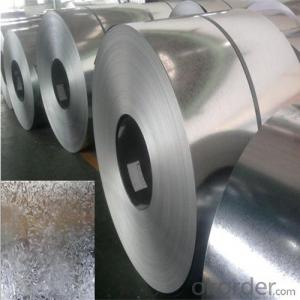

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

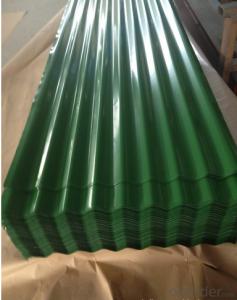

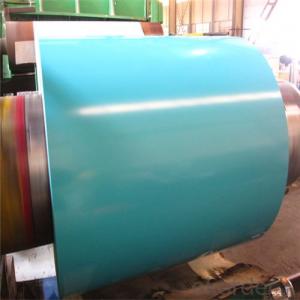

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the impact of coil defects on the performance and safety of automotive components?

Coil defects in automotive components can have a significant impact on their performance and safety. These defects can lead to malfunctions or failures in crucial systems such as the ignition, fuel injection, or electrical systems. This can result in poor engine performance, reduced fuel efficiency, or even complete breakdown of the vehicle. Moreover, coil defects can also pose safety hazards, as they can cause sudden engine stalls, loss of power steering, or malfunctioning of safety features like airbags or anti-lock braking systems. Therefore, addressing and rectifying coil defects is crucial to ensure optimal performance and safety of automotive components.

What are the advancements in coil processing technology for improved efficiency and precision?

Advancements in coil processing technology for improved efficiency and precision include the development of high-speed automated coil lines, advanced computer-controlled systems, and innovative tooling designs. These technologies enable faster coil processing, accurate material handling, and precise cutting, leveling, and slitting of coils. Additionally, advancements in sensors, robotics, and artificial intelligence have facilitated real-time data monitoring, quality control, and predictive maintenance, further enhancing efficiency and precision in coil processing.

How are steel coils prepared for the production of automotive exhaust systems?

Steel coils are prepared for the production of automotive exhaust systems by first undergoing a series of essential steps. These include leveling, cutting, and shaping the steel coils into specific dimensions required for the exhaust system components. The coils are then cleaned and treated to remove any impurities and enhance their durability. Finally, the prepared steel coils are ready to be used in the manufacturing process of automotive exhaust systems.

Wholesale Steel Coils from supplier in Iceland

Whether you require hot-rolled or cold-rolled steel coils, galvanized or pre-painted steel coils, we have you covered. Our steel coils are sourced from reputable manufacturers and undergo strict quality control measures to ensure that they meet the highest standards.

In addition to supplying steel coils, we also offer a range of value-added services to enhance your procurement experience. Our team of experts can assist you with product selection, provide technical support, and offer logistical solutions to ensure a smooth and efficient supply chain.

Furthermore, our local presence in Iceland allows us to understand the unique requirements and challenges of the market. We are well-versed in local regulations, industry trends, and customer preferences, enabling us to provide tailored solutions that meet your specific needs.

By partnering with us, you can benefit from our global network, extensive resources, and industry expertise. We strive to build long-term relationships with our clients, delivering reliable and cost-effective solutions that contribute to the success of your projects.

Contact us today to discuss your steel coil requirements and let us demonstrate how we can add value to your business in Iceland.

In addition to supplying steel coils, we also offer a range of value-added services to enhance your procurement experience. Our team of experts can assist you with product selection, provide technical support, and offer logistical solutions to ensure a smooth and efficient supply chain.

Furthermore, our local presence in Iceland allows us to understand the unique requirements and challenges of the market. We are well-versed in local regulations, industry trends, and customer preferences, enabling us to provide tailored solutions that meet your specific needs.

By partnering with us, you can benefit from our global network, extensive resources, and industry expertise. We strive to build long-term relationships with our clients, delivering reliable and cost-effective solutions that contribute to the success of your projects.

Contact us today to discuss your steel coil requirements and let us demonstrate how we can add value to your business in Iceland.