Spring Strip Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 500000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Spring Steel:

Spring steel is divided into two types, one is alloy spring steel, and other one is carbon spring steel.

Alloy spring steel is a type that is used for manufacturing springs and other elastic parts. Spring steel should have high ratio of yield strength and tensile strength and elastic limit to make sure that the springs obtain enough power of elastic deformation and can bear much load.

Types of alloy spring steel: Si-Mn spring steel, Si-Cr spring steel, Cr-Mn Spring steel, Cr-V spring steel and so on.

Specification of Spring Strip Steel:

-Material: 30W4Cr2VA

-Standard: GB/T 1222-2007

-Type: Spring Steel

Chemical Composition:

C | Si | Mn | S |

0.26~0.34 | 0.17~0.37 | ≤0.40 | ≤0.030 |

P | Cr | Ni | Cu |

≤0.030 | 2.00~2.50 | ≤0.35 | ≤0.25 |

V | W | ||

0.50~0.80 | 4.00~4.50 |

Mechanical Properties:

-Yield Strength σs (MPa): ≥1470 (150)

-Elongation δ10(%):≥7

-Hardness:

1, Hot rolled + Heat treatment, ≤321HB

2, Cold drawn + Heat treatment: ≤321HB

-Impact Power: ≥40

Norm of heat treatment:

1, Quenching: 1050℃~1100℃.

2, Cooled by oil.

3, Tempering: 600℃±50℃.

Usage/Applications of Spring Strip Steel:

-Due to the elements W, Cr and V, this type of spring steel obtain pretty high hardenability and nice mechanical properties under room temperature and high temperature. The tempering stability and hot workability are good.

-Being used under the state of quenching and high temperature tempering. It’s usually used as heat-resisting springs with working temperature below 500℃, like main secure valve spring of furnace and turbine steam seal leaf springs.

Packaging & Delivery of Spring Strip Steel:

-Packing Detail: The products will be well packed.

-Marks: there are two types of marks.

1, Tag marks. To show customers the specifications of products, company name and logo and other information required by customers.

2, Color marks. It’s easy for customers to distinguish them from other products at destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

Payment:

-Theoretical weight/Actual weight.

-FOB, CFR or CIF.

-Terms of payment: T.T. or L/C at sight.

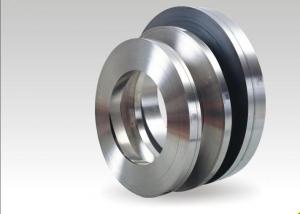

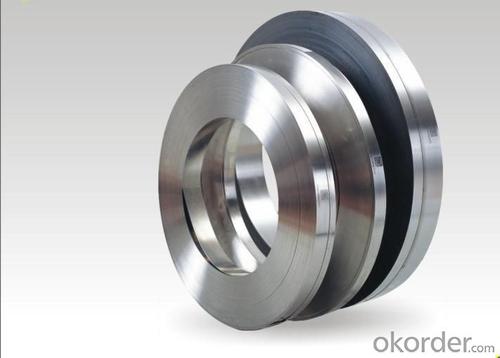

Photos of Spring Strip Steel:

- Q: What are the different surface treatment techniques for special steel?

- There are several surface treatment techniques available for special steel, including electroplating, hot-dip galvanizing, powder coating, and passivation. Electroplating involves depositing a layer of metal onto the steel surface through an electrochemical process, providing enhanced corrosion resistance and aesthetic appeal. Hot-dip galvanizing immerses the steel in molten zinc, forming a protective zinc coating that prevents rusting. Powder coating involves applying a dry powder onto the steel surface, which is then heated and fused to create a durable and decorative finish. Passivation is a chemical process that removes surface contaminants and forms a protective oxide layer on the steel, improving its corrosion resistance.

- Q: What are the applications of special steel in the oil and gas industry?

- Special steel has various applications in the oil and gas industry due to its superior properties and durability. It is commonly used in the construction of pipelines, offshore platforms, and drilling equipment, as it can withstand harsh environmental conditions and corrosion. Special steel is also utilized in the manufacturing of valves, fittings, and connectors, ensuring high-pressure and high-temperature resistance. Additionally, it is employed in the fabrication of storage tanks, heat exchangers, and other critical components, ensuring safety and reliability in the oil and gas operations.

- Q: How does special steel perform in extreme temperature conditions?

- Special steel is designed to perform exceptionally well in extreme temperature conditions. It has enhanced heat resistance and can withstand high temperatures without losing its strength or structural integrity. Additionally, special steel exhibits excellent thermal conductivity, allowing it to efficiently transfer heat away from critical components. Overall, special steel is highly reliable and durable in extreme temperature environments.

- Q: What are the main characteristics of wear-resistant steel?

- Wear-resistant steel, also referred to as abrasion-resistant steel, possesses distinct qualities that make it highly resistant to wear and tear. Wear-resistant steel exhibits the following key characteristics: 1. High hardness: Typically, wear-resistant steel is hardened to a significant degree, providing excellent resistance against abrasion, impact, and sliding wear. This hardness is achieved through processes like quenching and tempering, resulting in a steel material capable of enduring heavy loads and abrasive environments. 2. Exceptional toughness: Besides its high hardness, wear-resistant steel also showcases exceptional toughness. This means it can absorb impact and withstand heavy shocks without fracturing or breaking. This characteristic is crucial for applications requiring both abrasion and impact resistance, such as mining equipment and earthmoving machinery. 3. Superior strength: Known for its high strength, wear-resistant steel can withstand extreme forces and pressures. This strength is achieved through the use of alloys and heat treatment processes, resulting in a steel material capable of enduring heavy loads and resisting deformation even under intense wear conditions. 4. Excellent weldability: Wear-resistant steel is often designed with good weldability, allowing for easy joining or repairing using various welding techniques. This characteristic is significant as it permits the fabrication of wear-resistant components and the cost-effective repair of worn-out parts. 5. Corrosion resistance: Some wear-resistant steel grades are formulated to exhibit corrosion resistance properties. This ensures the steel remains intact and does not deteriorate when exposed to harsh environments, chemicals, or moisture. This characteristic is particularly useful in applications where wear and corrosion occur simultaneously, such as marine equipment or mining operations. 6. Extended service life: Due to its high hardness, exceptional toughness, superior strength, and corrosion resistance, wear-resistant steel offers an extended service life compared to other steel types. Its ability to withstand wear, impact, and abrasion allows for reduced downtime and maintenance costs, making it highly sought-after in industries like mining, construction, and manufacturing. Overall, the primary attributes of wear-resistant steel make it a reliable and durable material for applications involving prolonged exposure to abrasive conditions. Its unique properties ensure it can withstand heavy loads, resist wear and tear, and maintain its integrity, ultimately leading to improved equipment performance and cost savings.

- Q: What are the different surface finishing techniques for special steel parts?

- There are several surface finishing techniques that can be used for special steel parts to enhance their appearance, protect them from corrosion, and improve their overall performance. Some of the commonly used techniques include: 1. Polishing: This technique involves using abrasives to create a smooth and glossy surface on the steel part. It not only enhances the aesthetic appeal but also improves the part's resistance to corrosion. 2. Plating: Plating is a process that involves depositing a layer of metal onto the surface of the steel part. Common plating options include chrome, nickel, and zinc. This technique provides additional protection against corrosion, improves wear resistance, and can also give the part a desired color or finish. 3. Powder coating: Powder coating is a method where a dry powder is applied to the surface of the steel part electrostatically and then cured under heat. The powder melts and forms a hard, durable, and attractive coating. This technique provides excellent resistance to corrosion, impact, and chemicals. 4. Anodizing: Anodizing is primarily used for aluminum, but it can also be applied to some special steel parts. It involves creating a controlled oxide layer on the surface of the part, which enhances its corrosion resistance, improves its appearance, and can provide an insulation layer. 5. Passivation: Passivation is a chemical process that removes free iron and other contaminants from the surface of the steel part. It helps prevent corrosion and improves the part's resistance to staining or discoloration. 6. Heat treatment: Heat treatment is a process that involves heating and cooling the steel part to alter its physical and mechanical properties. It can improve hardness, strength, and toughness, while also providing a desired surface finish. 7. Electropolishing: Electropolishing is an electrochemical process that removes a thin layer of metal from the surface of the steel part. It helps eliminate surface imperfections, smoothens the part, and improves its corrosion resistance. It is important to choose the appropriate surface finishing technique based on the specific requirements of the special steel part, such as its function, desired appearance, and environmental conditions it will be exposed to.

- Q: What are the limitations of using special steel in electrical applications?

- Using special steel in electrical applications comes with several limitations. Firstly, it tends to be more expensive compared to other commonly used materials like copper or aluminum, making it less cost-effective for large-scale projects. Another drawback is its relatively high electrical resistivity, which hampers its efficiency in conducting electricity. This results in higher energy losses and lower overall efficiency in electrical systems, which is particularly concerning for energy-efficient applications like power generation or transmission. Moreover, special steel lacks the malleability and ductility found in materials like copper, making it less suitable for applications requiring shaping or forming. Working with it can be more challenging and may necessitate complex manufacturing processes. Furthermore, special steel is more susceptible to corrosion compared to materials like copper or aluminum. In environments with high humidity or moisture exposure, this can significantly limit its use in electrical applications. Corrosion not only degrades the steel's electrical properties but also reduces its lifespan, leading to increased maintenance and replacement costs. Lastly, special steel may not be as readily available or easily sourced as other materials commonly used in electrical applications. This can present challenges in terms of availability, lead times, and potential disruptions in the supply chain, ultimately impacting project timelines and overall productivity.

- Q: How does aluminum contribute to the properties of special steel?

- Aluminum is commonly added as an alloying element in special steel to enhance its properties. By adding aluminum to steel, several improvements can be achieved. Firstly, aluminum improves the strength of steel by forming a fine dispersion of aluminum nitride particles within the steel matrix. These particles act as barriers to dislocation movement, impeding the deformation of the steel and increasing its strength. This makes the steel more resistant to mechanical stresses and enhances its load-bearing capacity. Secondly, aluminum also enhances the corrosion resistance of steel. It forms a protective oxide layer on the surface of the steel, acting as a barrier against the corrosive agents. This oxide layer prevents the steel from oxidizing, rusting, and deteriorating over time, making it more durable and long-lasting in various environments. Additionally, aluminum can improve the machinability of special steel. Its presence in the steel composition reduces the tendency of the steel to work harden during machining operations. This makes it easier to cut, drill, or shape the steel, resulting in improved productivity and reduced tool wear. Moreover, aluminum contributes to the heat resistance of special steel. It has a high melting point and good thermal conductivity, which helps in maintaining the structural integrity of the steel at elevated temperatures. This makes aluminum-steel alloys suitable for applications where high-temperature resistance is required, such as in the aerospace and automotive industries. In summary, aluminum contributes significantly to the properties of special steel. It enhances the strength, corrosion resistance, machinability, and heat resistance of steel, making it a versatile material with a wide range of applications.

- Q: What are the different forms in which special steel is available?

- Special steel is available in various forms such as bars, plates, sheets, tubes, wires, and forgings.

- Q: How is leaded steel used in machining operations?

- Leaded steel is commonly used in machining operations as it improves the machinability of the steel by reducing friction and cutting forces. The addition of lead in the steel composition allows for smoother and more efficient cutting, resulting in better surface finish and dimensional accuracy of machined parts.

- Q: How does special steel contribute to improving product resistance to environmental factors?

- Special steel contributes to improving product resistance to environmental factors in several ways. Firstly, special steel alloys often have enhanced corrosion resistance, protecting the product from damage caused by exposure to moisture, chemicals, and other corrosive substances present in the environment. Additionally, special steel can offer improved strength and durability, enabling the product to withstand harsh conditions such as extreme temperatures, high pressure, or mechanical stress. Furthermore, special steel can exhibit excellent fatigue resistance, ensuring that the product maintains its structural integrity even after prolonged exposure to cyclic loading or repetitive stress. Overall, the unique characteristics of special steel make it a valuable material for enhancing the resistance of products to various environmental factors, ultimately prolonging their lifespan and reducing maintenance costs.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1990 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

Spring Strip Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 500000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords