All Categories

- - Steel Wire Rod

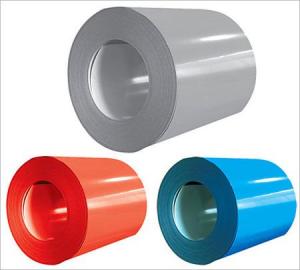

- - Steel Coils

- - Steel Profiles

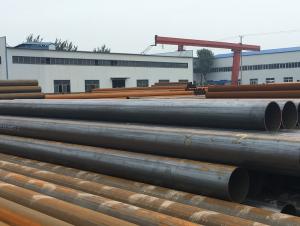

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

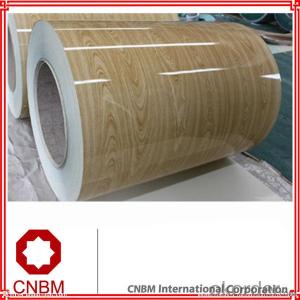

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the impact of tungsten in hot-rolled steel properties?

Tungsten has a significant impact on the properties of hot-rolled steel. It enhances the hardness, strength, and wear resistance of the steel, thereby improving its overall performance. Tungsten acts as a solid solution strengthener, refining the grain structure and increasing the steel's ability to withstand high temperatures and mechanical stresses. Additionally, tungsten helps to stabilize the austenite phase during hot rolling, preventing the formation of undesirable microstructures. Overall, the addition of tungsten in hot-rolled steel positively influences its mechanical properties, making it suitable for various demanding applications.

What is the cost difference between hot-rolled and cold-rolled steel?

The cost difference between hot-rolled and cold-rolled steel can vary depending on various factors such as market conditions, steel grade, and quantity ordered. Generally, hot-rolled steel is less expensive than cold-rolled steel due to the lower processing and production costs involved. However, it is important to note that the final cost difference can be influenced by other factors specific to each purchase.

How does the heat treatment affect the properties of hot rolled steel?

Heat treatment can significantly affect the properties of hot rolled steel by altering its microstructure and improving its mechanical properties. The process involves heating the steel to a specific temperature and then cooling it at a controlled rate. This can result in changes such as increased hardness, improved strength, and enhanced toughness. Additionally, heat treatment can also refine the grain structure, reducing the presence of impurities and improving the overall quality of the steel.

How does hot rolled steel respond to surface treatments like painting?

Hot rolled steel is generally receptive to surface treatments like painting. However, it is important to note that the effectiveness and durability of the paint job can be influenced by factors such as the steel's surface condition and the type of paint used. Proper surface preparation, including cleaning and priming, is crucial to ensure good adhesion and longevity of the paint coating on hot rolled steel.

Wholesale Hot Rolled Steel from supplier in Guyana

Whether you are looking for Hot Rolled Steel for construction, manufacturing, or any other application, our team of experts can assist you in finding the right products to meet your specific requirements. We understand the importance of timely deliveries and offer efficient logistics solutions to ensure that your orders are delivered on time.

Our sales team is highly knowledgeable and can provide you with accurate and competitive quotations for your Hot Rolled Steel needs. We take pride in our customer service and strive to exceed your expectations by offering personalized attention and support throughout the entire procurement process.

In addition to sales and quotations, we also offer technical support to help you make informed decisions about the right Hot Rolled Steel products for your projects. Our technical team is well-versed in the specifications and applications of Hot Rolled Steel and can provide guidance on the best options for your specific requirements.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources, ensuring that we can meet your Hot Rolled Steel needs efficiently and effectively. Our strong presence in the Guyanese market enables us to understand the local industry dynamics and provide valuable insights to help you make informed decisions.

In summary, we are dedicated to providing Guyana with convenient and efficient procurement solutions for Hot Rolled Steel. With our comprehensive services, extensive product range, and years of market experience, we are confident in our ability to meet your Hot Rolled Steel needs and support your projects effectively. Contact us today to discuss your requirements and let us assist you in finding the right Hot Rolled Steel products for your projects.

Our sales team is highly knowledgeable and can provide you with accurate and competitive quotations for your Hot Rolled Steel needs. We take pride in our customer service and strive to exceed your expectations by offering personalized attention and support throughout the entire procurement process.

In addition to sales and quotations, we also offer technical support to help you make informed decisions about the right Hot Rolled Steel products for your projects. Our technical team is well-versed in the specifications and applications of Hot Rolled Steel and can provide guidance on the best options for your specific requirements.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources, ensuring that we can meet your Hot Rolled Steel needs efficiently and effectively. Our strong presence in the Guyanese market enables us to understand the local industry dynamics and provide valuable insights to help you make informed decisions.

In summary, we are dedicated to providing Guyana with convenient and efficient procurement solutions for Hot Rolled Steel. With our comprehensive services, extensive product range, and years of market experience, we are confident in our ability to meet your Hot Rolled Steel needs and support your projects effectively. Contact us today to discuss your requirements and let us assist you in finding the right Hot Rolled Steel products for your projects.