Alloy Round Steel Bar 40Mn 50Mn 20CrNi4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy Round Steel Bar 40Mn 50Mn 20CrNi4

Product information

1. Produce Standard: GB, AISI, ASTM, SAE, EN, BS, DIN, JIS

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment: Normalized / Annealed / Quenched+Tempered

4. Quality assurance: All order we can received third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product detail

| Material | 40Mn 50Mn 20CrNi4 | Round bar | Dia(mm) | 16-600 |

| Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12000 | |

| Heat treatment | Normalized / Annealed / Quenched / tempered | Flat bar | Thickness(mm) | 8-500 |

| Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | 70-200 | |

| Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12000 | |

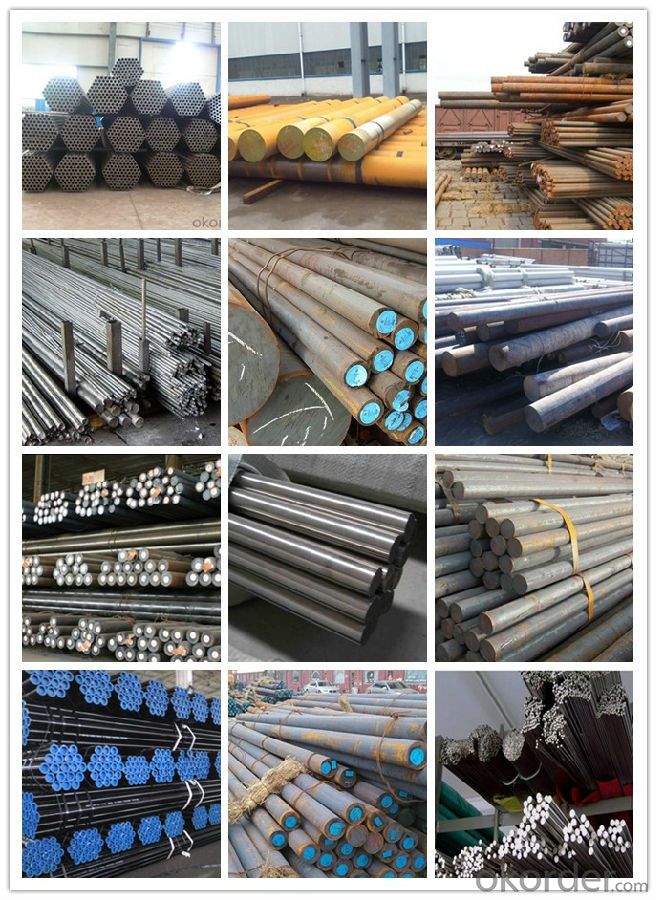

Product show

Work shop

Our Services

* Welcome to contact us with your detailed inquiry, you will be replied within 24 hours.

* You are promised to obtain the best quality, price and service.

* We'd like to provide samples for your confirm.

- Q: What are the different coating materials used for special steel?

- There are several different coating materials used for special steel, including zinc, aluminum, nickel, tin, and epoxy-based coatings. These coatings are applied to enhance the corrosion resistance, improve durability, and provide a decorative finish to the special steel.

- Q: What are the properties of carbon steel?

- Carbon steel is a type of steel that primarily consists of iron and carbon, with trace amounts of other elements. It is known for its strength, durability, and high melting point. Carbon steel is also highly malleable, making it easy to form into various shapes and structures. Additionally, it exhibits good corrosion resistance, although it is not as resistant as stainless steel. Overall, carbon steel is widely used in industries such as construction, automotive, and manufacturing due to its excellent mechanical properties.

- Q: How does special steel contribute to the oil and gas machinery industry?

- The oil and gas machinery industry heavily relies on special steel due to its wide range of essential properties and characteristics. Its exceptional strength and durability allow it to withstand the extreme forces and pressures involved in oil and gas extraction, transportation, and refining processes. This ensures reliable and efficient machinery operation, minimizing downtime and maintenance costs. Special steel also possesses excellent corrosion resistance, which is crucial in an industry where equipment is constantly exposed to corrosive environments like seawater, acidic gases, and high-temperature fluids. Using corrosion-resistant special steel increases machinery lifespan, reduces equipment failure risk, and enhances overall safety. Moreover, special steel exhibits high temperature resistance, which is vital in this industry where equipment operates at extremely high temperatures, especially in drilling, refining, and petrochemical production processes. Special steel alloys maintain their structural integrity under these elevated temperatures, ensuring safe and efficient machinery functioning. Additionally, special steel offers exceptional wear and abrasion resistance properties, making it ideal for components exposed to constant friction such as valves, pumps, and drilling tools. This wear and abrasion resistance prolongs component lifespan, reduces maintenance needs, and enhances overall machinery efficiency. In summary, special steel significantly contributes to the oil and gas machinery industry by providing the necessary strength, durability, corrosion resistance, high temperature resistance, and wear resistance required for demanding operating conditions. By utilizing special steel alloys, manufacturers can create robust and reliable machinery capable of withstanding the challenges of the oil and gas industry, ensuring the smooth and safe extraction, transportation, and processing of oil and gas resources.

- Q: How does special steel contribute to the heavy equipment industry?

- Special steel contributes to the heavy equipment industry by offering enhanced strength, durability, and resistance to wear and tear. It enables the production of high-performance components and parts, such as gears, axles, and blades, that can withstand heavy loads, extreme temperatures, and harsh environments. The use of special steel in heavy equipment ensures improved safety, increased productivity, and longer service life, making it a critical material for the industry.

- Q: What are the different methods for improving the tensile strength of special steel?

- There are several methods for improving the tensile strength of special steel. 1. Alloying: One common method is to add alloying elements such as chromium, nickel, molybdenum, or vanadium to the steel. These elements form solid solutions with the iron matrix, enhancing the strength and hardness of the steel. Alloying also improves the steel's resistance to corrosion and wear. 2. Heat treatment: Heat treatment is another effective method for increasing the tensile strength of special steel. Processes like quenching, tempering, and annealing are commonly used. Quenching involves rapidly cooling the steel from a high temperature, which creates a hardened microstructure. Tempering then reduces the brittleness and improves the toughness of the steel. Annealing, on the other hand, involves heating the steel to a specific temperature and then slowly cooling it, which can refine the grain structure and enhance its strength. 3. Cold working: Cold working, also known as cold rolling or cold drawing, involves subjecting the steel to plastic deformation at low temperatures. This process increases the dislocation density in the steel, resulting in strain hardening and improved strength. Cold working can significantly enhance the tensile strength of special steel. 4. Grain refinement: Refining the grain structure of the steel can also improve its tensile strength. This can be achieved through processes like recrystallization annealing, which involves heating the steel to a specific temperature and then cooling it slowly to promote the formation of smaller and more uniform grains. Smaller grain size leads to increased strength and improved mechanical properties. 5. Shot peening: Shot peening is a technique that involves bombarding the surface of the steel with small metallic or ceramic particles. This process induces compressive stresses in the surface layer of the steel, which helps to inhibit crack initiation and propagation, ultimately improving the tensile strength and fatigue resistance of the steel. It is important to note that the choice of method for improving tensile strength depends on the specific application and requirements of the special steel. Various combinations of these methods can be employed to achieve the desired mechanical properties.

- Q: How does special steel contribute to the energy generation industry?

- Special steel contributes to the energy generation industry by providing high-strength, corrosion-resistant, and heat-resistant materials that are crucial for the construction and maintenance of power plants, turbines, and other energy infrastructure. This ensures the reliability, efficiency, and longevity of these structures, enabling them to withstand extreme conditions and maximize energy production.

- Q: How is special steel used in the production of cutting blades?

- Special steel is used in the production of cutting blades because it possesses unique properties that make it highly durable, resistant to wear and tear, and capable of maintaining a sharp edge for longer periods of time. This type of steel is often chosen for its high hardness, toughness, and corrosion resistance, making it ideal for manufacturing cutting blades that can withstand intense cutting forces and harsh working environments.

- Q: Can special steel be used in the aerospace industry?

- Yes, special steel can be used in the aerospace industry. Special steel alloys, such as stainless steel and titanium alloys, possess excellent strength, corrosion resistance, and heat resistance properties required for aircraft components. These materials are commonly used in critical applications like engine parts, landing gears, and structural components to ensure high performance and safety in aerospace operations.

- Q: How does special steel contribute to the manufacturing of fasteners?

- Special steel is an essential material in the manufacturing of fasteners due to its unique properties and characteristics. Firstly, special steel offers high strength and durability, making it ideal for the production of fasteners that are required to withstand heavy loads and high levels of stress. This ensures that the fasteners can securely hold components together without breaking or becoming loose over time. Additionally, special steel is known for its excellent corrosion resistance. Fasteners are often exposed to various environmental conditions, including moisture, chemicals, and extreme temperatures. The corrosion resistance of special steel helps to prevent rust and deterioration, ensuring the longevity and reliability of the fasteners. Furthermore, special steel can be easily formed, machined, and heat-treated, allowing for the production of fasteners with precise dimensions and customized designs. This versatility in manufacturing processes enables the creation of fasteners that can meet specific application requirements, such as different thread types, sizes, and head styles. Moreover, special steel offers excellent wear resistance and hardness, which is crucial for fasteners that are subjected to repetitive motions or constant friction. The hardness of special steel helps the fasteners maintain their shape and integrity, reducing the risk of deformation or failure during operation. Overall, special steel plays a vital role in the manufacturing of fasteners by offering high strength, corrosion resistance, versatility in manufacturing processes, and excellent wear resistance. These properties ensure that fasteners are reliable, long-lasting, and capable of withstanding the demands of various industries, including automotive, aerospace, construction, and machinery.

- Q: How is corrosion-resistant steel different from regular steel?

- Corrosion-resistant steel, also known as stainless steel, is different from regular steel because it contains a higher proportion of chromium and other alloying elements. These elements form a protective layer on the surface of the steel, preventing it from rusting or corroding when exposed to moisture or aggressive environments. Regular steel, on the other hand, lacks this protective layer and is more prone to rust and corrosion.

Send your message to us

Alloy Round Steel Bar 40Mn 50Mn 20CrNi4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords