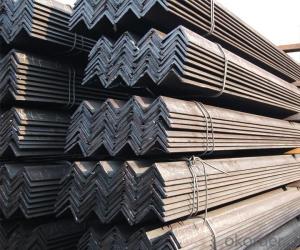

Unequal Steel Angle Hot Selling Various High Quality, Angle Steel, Angle Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Steel Angle Hot Selling Various High Quality Angle Steel Angle Bars at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Steel Angle Hot Selling Various High Quality, Angle Steel, Angle Bars are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Steel Angle Hot Selling Various High Quality, Angle Steel, Angle Bars are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1 .Materials:Q195/ Q235/ Q345/ ST-37/ ST-52/ SS400/ S235JR/ S275JR

2. Standard: ASTM,AISI, BS, DIN, GB, JIS

3. Type:Equal angle and Unequal

4.Size:20-200mm 75*50mm-200*100mm L:6-12m or cut as your request

| Unequal Angle | |||||||||

| Specification(mm) | Theoretical Weight(kg/m) | Specification(mm) | Theoretical Weight(kg/m) | ||||||

| 75*50*6 | 5.67 | 125*75*7 | 10.7 | ||||||

| 75*50*8 | 7.35 | 125*75*8 | 12.2 | ||||||

| 100*75*6 | 8.04 | 125*75*9 | 13.6 | ||||||

| 100*75*7 | 9.32 | 125*75*10 | 15 | ||||||

| 100*75*8 | 10.6 | 125*75*12 | 17.8 | ||||||

| 100*75*9 | 11.8 | 150*90*9 | 16.4 | ||||||

| 100*75*10 | 13 | 150*90*10 | 18.2 | ||||||

| 100*75*12 | 15.4 | 150*90*12 | 21.5 | ||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

- Q: Can steel angles be customized or fabricated to specific requirements?

- Yes, steel angles can be customized or fabricated to specific requirements.

- Q: What are the standard sizes of steel angles?

- The region and industry dictate the standard sizes of steel angles, although there are widely utilized common sizes. Steel angles generally come in equal leg and unequal leg sizes. Equal leg angles have standard sizes ranging from 20x20mm to 200x200mm, with thicknesses ranging from 3mm to 26mm. Unequal leg angles have one leg longer than the other, and their standard sizes range from 25x16mm to 200x150mm, with thicknesses ranging from 3mm to 15mm. These standard sizes find widespread use in construction, engineering, and manufacturing industries for various purposes, including structural supports, framing, and bracing. It is worth noting that these sizes may differ based on project-specific requirements or industry-regulated standards.

- Q: What are the different types of steel angles connections for beams?

- There are several types of steel angle connections for beams, including bolted connections, welded connections, and riveted connections. Bolted connections involve using bolts and nuts to secure the angles to the beams, providing a strong and adjustable connection. Welded connections involve melting the angles and beams together using heat, creating a permanent and sturdy connection. Riveted connections involve using metal rivets to fasten the angles and beams together, offering a reliable and durable connection. Each type of connection has its own advantages and may be chosen based on factors such as structural requirements and ease of installation.

- Q: Can steel angles be used for framing or supporting exterior façade elements?

- Yes, steel angles can be used for framing or supporting exterior façade elements. Steel angles are commonly used in construction for their strength and durability. They provide a stable and reliable support system for various architectural elements, including exterior façade elements. Steel angles can be used to frame windows, doors, and other openings in the exterior walls. They can also be used to reinforce and support the weight of exterior cladding materials such as stone, glass, or metal panels. Steel angles are versatile and can be easily customized to fit the specific requirements of the project. They are often preferred in commercial and industrial buildings where structural stability is of utmost importance.

- Q: What are the different types of steel angle connections?

- There are several different types of steel angle connections, including bolted connections, welded connections, and hybrid connections. Bolted connections involve using bolts and nuts to connect steel angles together. Welded connections involve melting the steel angles together using heat and a welding process. Hybrid connections combine elements of both bolted and welded connections, using a combination of bolts and welding to secure the steel angles together.

- Q: How do you store steel angles to prevent damage?

- To prevent damage and maintain the integrity of steel angles, it is crucial to adhere to certain best practices. Firstly, one must ensure that the storage area remains clean, devoid of any moisture or humidity. The presence of moisture can lead to corrosion and rusting, which can progressively harm the angles. It is highly recommended to store steel angles indoors, in a well-ventilated space, away from direct sunlight and extreme temperature changes. This precautionary measure aids in minimizing the risk of potential damage caused by exposure to natural elements. When stacking steel angles, it is of utmost importance to employ appropriate supports or racks to prevent them from bending or warping under their own weight. Avoiding excessive stacking height is essential, as it can lead to instability and potential accidents. Incorporating pallets or other suitable storage systems can effectively preserve the angles' integrity and reduce the likelihood of damage. Furthermore, it is advisable to separate steel angles of different sizes and types to prevent scratching, chipping, or any other physical damage. Placing protective materials, such as plastic or rubber mats, between layers or individual angles can provide an additional layer of safeguarding. Regular inspections of the storage area play a critical role in identifying any signs of early damage, such as rust spots or deformation. In the event of any issues, addressing them promptly is vital to prevent further deterioration and ensure the quality of the steel angles.

- Q: How are steel angles measured?

- Steel angles are measured using two main dimensions: the length of each leg and the thickness of the material. The length of each leg refers to the distance from the intersection point of the two legs to the end of each leg. This measurement is usually expressed in inches or millimeters. The thickness of the material, also known as the gauge, is the measurement of the width of the steel angle. It is typically expressed in fractions of an inch or in millimeters. To provide a comprehensive measurement, steel angles are often described using a combination of these two dimensions. For example, a common specification could be "2 x 2 x 1/4," indicating that the steel angle has legs measuring 2 inches in length, a thickness of 1/4 inch, and both legs are equal in length. It is important to note that steel angles can be measured differently depending on the specific industry or region. Some industries may use metric measurements, while others may use imperial measurements. Therefore, it is always advisable to verify the measuring standards used in a particular context to ensure accurate understanding and communication.

- Q: What are the different methods of surface preparation for painting steel angles?

- There are several methods of surface preparation for painting steel angles, each of which have their own benefits and considerations. 1. Manual cleaning: This method involves using hand tools such as wire brushes, sandpaper, or scrapers to remove loose rust, mill scale, and other contaminants. While it is a cost-effective option, it may not be suitable for large-scale projects or areas that are difficult to access. 2. Power tool cleaning: Power tools like grinders, sanders, or wire wheels can be used to mechanically remove rust, scale, and old paint from the surface of steel angles. This method is more efficient than manual cleaning and can be used in larger projects, but proper safety precautions and protective gear should be used. 3. Chemical cleaning: Chemical cleaning involves using solvents or acidic solutions to dissolve rust and remove contaminants from the steel surface. This method is effective for heavily corroded or hard-to-reach areas, but it requires careful handling and disposal of the chemicals. 4. Abrasive blasting: Abrasive blasting, also known as sandblasting, uses compressed air to propel abrasive materials such as sand, grit, or glass beads onto the surface of steel angles. This method is highly effective in removing all types of contaminants, providing a clean and rough surface for paint adhesion. However, it requires specialized equipment and should be conducted by trained professionals due to potential health hazards. Regardless of the method chosen, it is essential to ensure that the steel angles are thoroughly cleaned and free from contaminants before painting. This will help to achieve better paint adhesion, prolong the lifespan of the coating, and enhance the overall durability of the steel structure.

- Q: Can steel angles be used in industrial or heavy-duty applications?

- Yes, steel angles can be widely used in industrial or heavy-duty applications due to their high strength, durability, and versatility. They are commonly utilized in construction, infrastructure, manufacturing, and fabrication industries for various purposes such as supporting structures, framing, bracing, and reinforcement. Their ability to withstand heavy loads and provide stability makes them suitable for demanding environments where strength and resilience are crucial.

- Q: Can steel angles be used in construction?

- Indeed, construction can utilize steel angles. Due to their versatility, strength, and cost-effectiveness, steel angles are frequently employed as structural elements in construction endeavors. Their primary purpose is to support and reinforce various structural components, including beams, columns, and walls. Various sizes and thicknesses of steel angles are available, allowing for a wide range of applications in construction. They can be easily joined together through welding, bolting, or fastening, facilitating convenient on-site installation and customization. A key advantage of incorporating steel angles in construction lies in their high strength-to-weight ratio. This attribute enables steel angles to possess outstanding load-bearing capacity while remaining relatively lightweight, rendering them highly suitable for structures that necessitate strength without excessive weight. Moreover, steel angles exhibit excellent durability and resistance against environmental factors such as corrosion, fire, and pests. Consequently, structures constructed with steel angles boast extended lifespans and require minimal maintenance over time. In summary, steel angles offer a versatile and dependable option for construction projects, regardless of whether they are residential, commercial, or industrial in nature. Architects, engineers, and contractors commonly favor steel angles due to their strength, durability, and ease of installation.

Send your message to us

Unequal Steel Angle Hot Selling Various High Quality, Angle Steel, Angle Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords