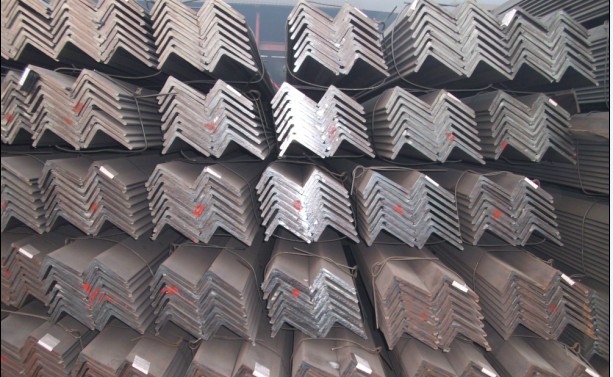

Angle Steel, Hot Rolled Steel Angle Bars, Unequal Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

angle steel

1.size:25*16*3mm-200*125*18mm

2.quality:Q235,Q345,SS400,A36

3.length: 6m, 9m, 12m

4.unequal

angle steel

angle steel

(1)Material:Q235 SS400 S235JR OR ST37-2 Q345

(2)Size:25x16x3mm-200x125x18mm

(3)Certificate:ISO,CE

angle steel

Size of unequal angle steel

| B(mm) | b(mm) | d(mm) | Theoretic Weight(kg/m) | |

| 25 | 16 | 3 | 0.912 | |

| 25 | 16 | 4 | 1.176 | |

| 32 | 20 | 3 | 1.171 | |

| 32 | 20 | 4 | 1.522 | |

| 40 | 25 | 3 | 1.484 | |

| 40 | 25 | 4 | 1.936 | |

| 45 | 28 | 3 | 1.687 | |

| 45 | 28 | 4 | 2.203 | |

| 50 | 32 | 3 | 1.908 | |

| 50 | 32 | 4 | 2.494 | |

| 56 | 36 | 3 | 2.153 | |

| 56 | 36 | 4 | 2.818 | |

| 56 | 36 | 5 | 3.466 | |

| 63 | 40 | 4 | 3.185 | |

| 63 | 40 | 5 | 3.92 | |

| 63 | 40 | 6 | 4.638 | |

| 63 | 40 | 7 | 5.339 | |

| 70 | 45 | 4 | 3.57 | |

| 70 | 45 | 5 | 4.403 | |

| 70 | 45 | 6 | 5.218 | |

| 70 | 45 | 7 | 6.011 | |

| 75 | 50 | 5 | 4.808 | |

| 75 | 50 | 6 | 5.699 | |

| 75 | 50 | 8 | 7.431 | |

| 75 | 50 | 10 | 9.098 | |

| 80 | 50 | 5 | 5.005 | |

| 80 | 50 | 6 | 5.935 | |

| 80 | 50 | 7 | 6.848 | |

| 80 | 50 | 8 | 7.745 | |

| 90 | 56 | 5 | 5.661 | |

| 90 | 56 | 6 | 6.717 | |

| 90 | 56 | 7 | 7.756 | |

| 90 | 56 | 8 | 8.779 | |

| 100 | 63 | 6 | 7.55 | |

| 100 | 63 | 7 | 8.722 | |

| 100 | 63 | 8 | 9.878 | |

| 100 | 63 | 10 | 12.142 | |

| 100 | 80 | 6 | 8.35 | |

| 100 | 80 | 7 | 9.656 | |

| 100 | 80 | 8 | 10.946 | |

| 100 | 80 | 10 | 13.476 | |

| 110 | 70 | 6 | 8.35 | |

| 110 | 70 | 7 | 9.656 | |

| 110 | 70 | 8 | 10.946 | |

| 110 | 70 | 10 | 13.476 | |

| 125 | 80 | 7 | 11.066 | |

| 125 | 80 | 8 | 12.511 | |

| 125 | 80 | 10 | 15.474 | |

| 125 | 80 | 12 | 18.33 | |

| 140 | 90 | 8 | 14.16 | |

| 140 | 90 | 10 | 17.475 | |

| 140 | 90 | 12 | 20.724 | |

| 140 | 90 | 14 | 23.908 | |

| 160 | 100 | 10 | 19.872 | |

| 160 | 100 | 12 | 23.592 | |

| 160 | 100 | 14 | 27.247 | |

| 160 | 100 | 16 | 30.835 | |

| 180 | 110 | 10 | 22.273 | |

| 180 | 110 | 12 | 26.464 | |

| 180 | 110 | 14 | 30.589 | |

| 180 | 110 | 16 | 34.649 | |

| 200 | 125 | 12 | 29.761 | |

| 200 | 125 | 14 | 34.436 | |

| 200 | 125 | 16 | 39.045 | |

| 200 | 125 | 18 | 43.588. | |

angle steel

angle steel

- Q: What are the standard lengths for steel angles?

- The standard lengths for steel angles can vary depending on the manufacturer and specific requirements, but common lengths range from 20 feet to 40 feet.

- Q: Are steel angles suitable for conveyor systems?

- Yes, steel angles are suitable for conveyor systems. Steel angles are often used in conveyor systems due to their strength, durability, and versatility. They provide a rigid structure that can support heavy loads and withstand the continuous motion and vibrations of a conveyor system. Steel angles can be easily welded or bolted together to create the framework for the conveyor system, allowing for easy customization and modification. Additionally, steel angles are resistant to corrosion, making them suitable for various environments and applications.

- Q: What is the maximum length of a continuous steel angle?

- The maximum length of a continuous steel angle typically depends on various factors such as the manufacturing process, transportation limitations, and structural requirements. However, in general, the maximum length of a continuous steel angle can range anywhere from a few meters to several tens of meters.

- Q: What are the common surface finishes for steel angles?

- Some common surface finishes for steel angles include painted, galvanized, and mill finish.

- Q: Are steel angles resistant to impact?

- Yes, steel angles are generally resistant to impact due to their high strength and durability. They are commonly used in construction and structural applications where impact resistance is required.

- Q: What is the difference between hot-rolled and cold-formed steel angles?

- Hot-rolled steel angles and cold-formed steel angles find use in various construction and industrial applications, but they differ in how they are made and the characteristics they possess. To produce hot-rolled steel angles, a steel billet or slab is heated above its recrystallization temperature and then passed through rollers to shape it as desired. This process allows for the creation of bends, curves, and other intricate angles. Hot rolling also leads to a rougher surface finish and slightly rounded edges, which can be advantageous in certain applications. Furthermore, hot-rolled steel angles are available in a wider range of sizes and thicknesses. On the other hand, cold-formed steel angles are formed by bending a flat strip of steel at room temperature using dies and rolls. This process does not involve heating the steel, preserving its existing physical properties. Consequently, cold-formed steel angles have a smoother surface finish and sharper, more defined edges compared to hot-rolled angles. The cold-forming process also enables tighter tolerances and more precise dimensions. Regarding mechanical properties, hot-rolled steel angles generally exhibit higher tensile strength and yield strength than cold-formed angles. This can be attributed to the heat treatment involved in hot rolling, which refines the grain structure and enhances the overall strength of the steel. Cold-formed steel angles, while typically less strong, are often preferred when weight reduction is a priority, as they are generally lighter than their hot-rolled counterparts. In conclusion, the main distinctions between hot-rolled and cold-formed steel angles lie in their manufacturing processes, resulting surface finishes, dimensional precision, and mechanical properties. The choice between the two depends on the specific requirements and limitations of the given project.

- Q: Can steel angles be used for framing partitions and walls?

- Yes, steel angles can be used for framing partitions and walls. Steel angles are commonly used in construction for their strength and durability. They can be used to create a framework for partitions and walls by providing structural support and stability. Steel angles are versatile and can be easily cut and welded to fit the desired dimensions and angles. They are also resistant to fire, pests, and moisture, making them a suitable choice for framing interior walls and partitions in both commercial and residential buildings.

- Q: What are the disadvantages of using steel angles?

- Some disadvantages of using steel angles include their susceptibility to corrosion and rust, limited design options due to their fixed angle shape, and their heaviness which can make them difficult to handle and install. Additionally, steel angles may require additional reinforcement and support to prevent bending or twisting under heavy loads.

- Q: What is the maximum load capacity for a steel angle bracket?

- The maximum load capacity of a steel angle bracket is influenced by several factors, including the bracket's dimensions, the quality and thickness of the steel employed, the installation method, and the intended purpose. Steel angle brackets are typically crafted to withstand substantial weight and support hefty loads. Nevertheless, it is imperative to refer to the manufacturer's specifications or engineering guidelines for the particular bracket under consideration to ascertain its maximum load capacity. These specifications will furnish precise details regarding the safe weight or load that the steel angle bracket can support without jeopardizing its structural integrity.

- Q: What size does angle iron 125*10 mean?

- The width of the equal angles is 125mm and the thickness is 10mm

Send your message to us

Angle Steel, Hot Rolled Steel Angle Bars, Unequal Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords