Unequal Angle Bars Hot sales&Free Sample Stainless Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | stainless steel unequal angle bars standard seaworthy packing(plastic&wooden) or according to the customer's requests |

| Delivery Detail: | stainless steel unequal angle bars delivey time is 15-25 days |

Specifications

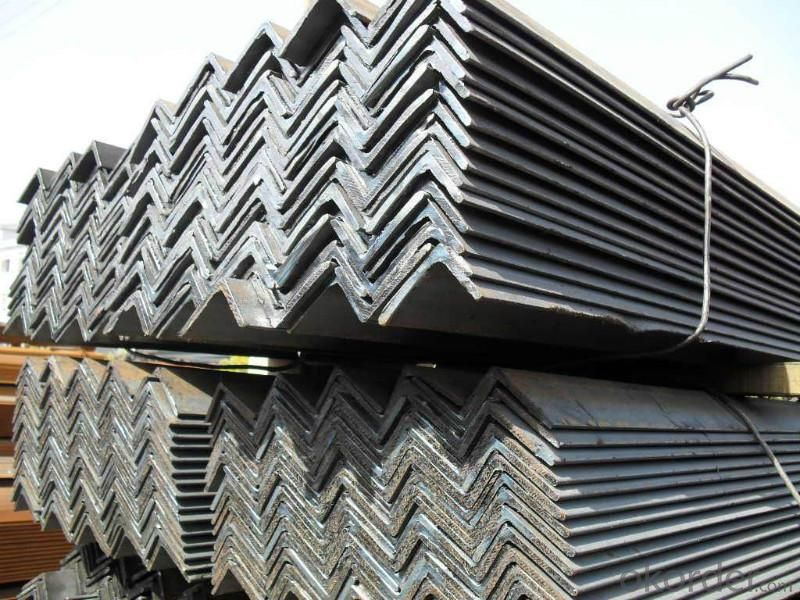

stainless steel unequal angle bars

1.Plentiful storage and short delivery time

2.direct factory sales

3.Reasonable price

stainless steel unequal angle bar

Product Description

basic information

Standard | AISI,ASTM,DIN,GB,JIS |

Material | 201,202,301,304,304L,316,316L,321,410,420,430etc |

Surface | bright , polished , sand blasting ,Cold drawn , hot rolled, etc |

Diameter | 2.5#,3#,4#,5#,6#,7#,7.5#,8#,10# |

Length | 6mter or as your requirement |

Packing | seaworthy packing(plastic & wooden) or according to the customer's requests |

MOQ | 0.5TON |

Delivery time | 15-25 days, as quanlity |

Application | These products are widely used in all kinds of architecture and engineering structure, such as the beam, Bridges, transmission tower, hoisting, ship industrial furnace, container frame and warehouse and Other fields. |

Contacts | If you are interested in our product, please feel free to contact us. Welcome your requires and hope we can establish friendly and long cooperative relations |

product picture

bright surface

why choose us?

1.In each manufacturing process,we arrange a technician in charge of inspection to make sure the final product completely qualified.

2.We take more machanized operations to decrease human labor cost.

3.We have an experienced term available to serve you,and supply you all you want.

4.In case of any problems occurs to our products you receive,we will redeliver them to you,or refund your payment,or solve it as the method we negotiate.

- Q:Can steel angles be used for stair stringers?

- Yes, steel angles can be used for stair stringers. Steel angles provide strong support and stability, making them a suitable choice for constructing stair stringers.

- Q:How do you determine the required number of fasteners for a steel angle connection?

- To determine the required number of fasteners for a steel angle connection, several factors need to be considered. These include the load being applied, the size and thickness of the angle, the type and strength of the fasteners being used, and any applicable building codes or engineering standards. Typically, calculations or guidelines provided by structural engineers or industry standards are used to determine the minimum number and spacing of fasteners needed to ensure the connection is strong and safe.

- Q:What are the different types of connections used for steel angles in structural applications?

- There are several types of connections that are commonly used for steel angles in structural applications. These connections are crucial for ensuring the stability and strength of the overall structure. 1. Welded connections: Welding is one of the most common methods used to connect steel angles. It involves melting the edges of the steel angles together to form a strong bond. Welded connections are typically used in applications where high strength and rigidity are required. 2. Bolted connections: Bolted connections involve using bolts and nuts to secure the steel angles together. This type of connection provides flexibility as it allows for disassembly and reassembly if needed. Bolted connections are often used in situations where ease of installation and maintenance is important. 3. Riveted connections: Riveting is a traditional method of joining steel angles. It involves inserting a rivet through holes in the steel angles and then flaring the ends to secure them in place. Riveted connections are known for their durability and resistance to corrosion. However, they are less commonly used today due to the time-consuming installation process. 4. Clip connections: Clip connections involve using metal clips or brackets to attach the steel angles. These clips are typically welded or bolted to the steel angles and provide a quick and efficient method of connection. Clip connections are often used in applications where speed and ease of installation are important factors. 5. Gusset plate connections: Gusset plates are steel plates that are used to connect steel angles at their intersection points. They are typically welded or bolted to the angles and provide additional strength and stability to the connection. Gusset plate connections are commonly used in situations where larger forces and moments need to be transferred. Each type of connection has its own advantages and disadvantages, and the choice of connection method depends on several factors including the structural requirements, loadings, and the specific application. It is important to consider the design and engineering specifications to ensure that the chosen connection method is suitable for the intended use in structural applications.

- Q:Can steel angles be used for fencing or security applications?

- Certainly! Steel angles have a wide range of applications, including fencing and security. In construction, steel angles are widely utilized due to their exceptional strength and durability. When employed for fencing purposes, steel angles offer a solid framework capable of enduring adverse weather conditions and potential impacts. By welding or bolting them together, a secure and resilient fence structure can be created. Moreover, steel angles are also suitable for security applications like gates, barriers, and grills. Their robustness makes them an excellent option for reinforcing security measures and guaranteeing the safety of a property.

- Q:How do steel angles perform under extreme temperatures?

- Steel angles typically perform well under extreme temperatures. Steel is known for its high thermal conductivity, which means it can quickly absorb and distribute heat. This property helps steel angles to withstand extreme temperatures without significant deformation or failure. However, it is important to note that the specific performance of steel angles under extreme temperatures can vary depending on factors such as the alloy composition and heat treatment of the steel. In some cases, steel angles may experience reduced strength or become more susceptible to corrosion at extremely high temperatures. It is recommended to consult with a materials engineer or refer to the manufacturer's specifications to determine the specific performance of steel angles under the desired extreme temperature conditions.

- Q:What are the different types of connections for steel angles?

- Depending on the specific application and load requirements, there are various connection types available for steel angles. Some commonly used connections for steel angles include: 1. Welded connections: The most frequently employed connection type for steel angles involves welding the angle to the supporting structure or to another angle, creating a strong and rigid connection. Welded connections are typically utilized in applications where high load capacity and stability are essential. 2. Bolted connections: Bolts are used to connect the steel angles to the supporting structure or to other angles in bolted connections. This connection type allows for easy assembly and disassembly, making it suitable for applications where flexibility and adjustability are important. 3. Riveted connections: In riveted connections, rivets are used instead of bolts to secure the steel angles. This type of connection offers a robust and durable connection and is commonly found in structural applications. 4. Clip connections: Clip connections involve the use of steel clips to connect the angles to the supporting structure. This connection type is often employed in applications where ease of installation and flexibility are prioritized. 5. Moment connections: Moment connections are utilized to transfer bending moments between steel angles and the supporting structure. These connections are specifically designed to provide rigidity and stability in applications where high load capacity and resistance to lateral forces are required. 6. Gusset plate connections: Gusset plate connections involve the use of steel plates to connect the steel angles to the supporting structure. These connections provide additional strength and stability and are commonly employed in applications where heavy loads and high stresses are anticipated. It is important to consider various factors, such as the specific application, load requirements, and design considerations when selecting the appropriate connection type. Consulting with a structural engineer or a professional in steel construction is recommended to ensure the suitability of the chosen connection type for a specific project.

- Q:What are the common welding techniques used for steel angles?

- The common welding techniques used for steel angles include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW).

- Q:Are steel angles corrosion resistant?

- Steel angles are generally not corrosion resistant unless they are specifically designed and treated to be so. Regular steel angles are made from carbon steel, which is susceptible to corrosion when exposed to moisture, oxygen, and other corrosive elements. However, there are stainless steel angles available that have a higher resistance to corrosion due to the addition of chromium and other alloying elements. These stainless steel angles are commonly used in environments where corrosion is a concern, such as marine or industrial applications. It is important to consider the specific type and grade of steel angle being used to determine its corrosion resistance capabilities.

- Q:How do you transport steel angles?

- Steel angles can be transported by various means, including flatbed trucks, trailers, or shipping containers. It is important to securely fasten and stack the angles to prevent movement or damage during transportation. Additionally, using appropriate lifting equipment, such as cranes or forklifts, is necessary to load and unload the angles safely.

- Q:What are the different methods of impact testing for steel angles?

- There are several methods of impact testing that can be used to assess the toughness and resistance of steel angles. These methods include the Charpy V-notch test, the Izod test, and the drop weight test. 1. Charpy V-notch Test: This is one of the most commonly used methods for impact testing. In this test, a notched specimen of the steel angle is placed in a pendulum hammer. The hammer is released, swinging down and striking the specimen. The amount of energy absorbed by the specimen before it fractures is measured and used to determine the impact toughness of the material. 2. Izod Test: Similar to the Charpy V-notch test, the Izod test involves using a pendulum hammer to strike a notched specimen of the steel angle. However, in this test, the specimen is clamped vertically, while the hammer strikes it horizontally. The energy absorbed by the specimen is measured and used to evaluate its impact resistance. 3. Drop Weight Test: This method involves dropping a weight onto a specimen of the steel angle from a certain height. The specimen is usually supported on a solid base, and the impact energy is calculated based on the weight and the height of the drop. The deformation and fracture behavior of the specimen are then analyzed to determine its impact toughness. These different methods of impact testing help engineers and manufacturers assess the ability of steel angles to withstand sudden impact or shock loads. By evaluating the toughness and resistance of the material, these tests provide valuable information for designing structures and selecting appropriate materials for various applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Unequal Angle Bars Hot sales&Free Sample Stainless Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords