Corundum Brick - Bonded Corundum Fire Brick Materials

- Loading Port:

- DALIAN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

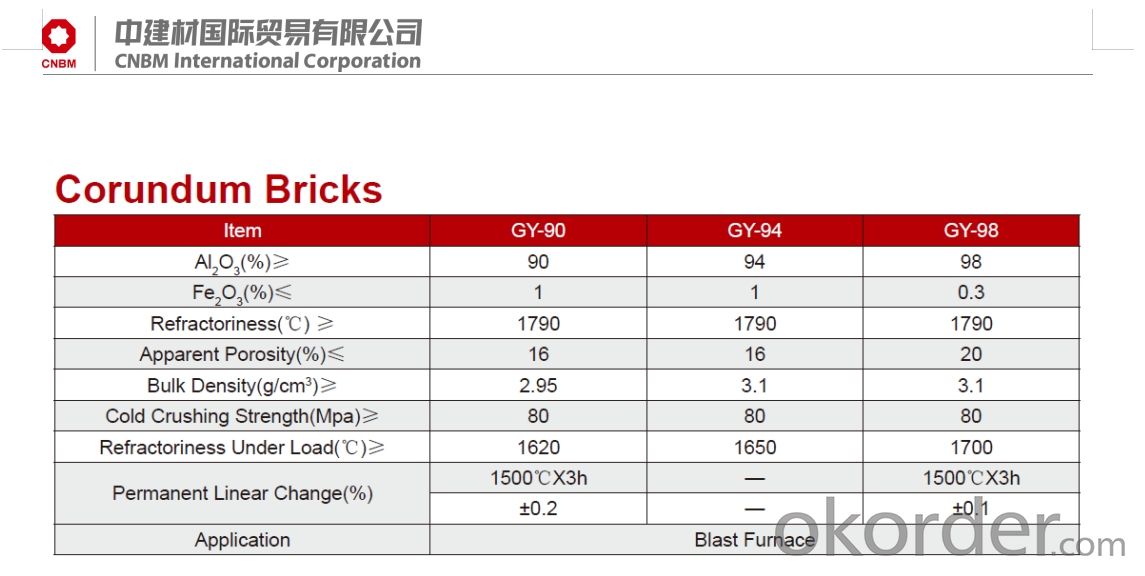

Corundum Brick

Corundum bricks is a kind of refractory brick with Al2O3 content more than 90% and corundum as the main crystal phase. Corundum bricks can be divided into sintered corundum bricks and fused corundum bricks.

Main Feature

1.Good chemical stability.

2.Good acid and alkali resistance and slag resistance.

3.Good corrosion resistance to metal and glass liquid.

Main Application

Used in the steel industry, non-ferrous smelting industry, carbon black industry, petroleum industry, chemical industry, fertilizer industry, etc.

- Q: How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q: What refractory materials are used in industrial furnaces?

- Economically, it is necessary to do technical and economic analysis when selecting materials reasonably. Under the premise that the technical indexes agree with the working conditions of the furnace, the refractory materials with low quoted price should be used as much as possible, without high-grade finished products. To think about whether to make self (such as irrigation, refractory concrete) as far as possible to repair old.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: High temperature refractory material?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay brick is siliceous. Products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste brick. Acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high that is close to the refractory, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. Silica is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly brick for glass furnaces and used for coke oven two kinds of brick clay brick. With refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, wide application Pan, clay brick with refractory clay as main raw material is called ordinary clay brick, made with bauxite clinker as main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay brick and according to the physicochemical indexes which were divided into several grades, the price difference between ordinary clay brick and low porosity clay brick greatly.

- Q: What kind of refractory material will be used in the glass kiln?

- It has the best resistance to high temperature E glass corrosion, its erosion basically does not cause pollution to the glass liquid, so it has become the first choice of E glass unit refractory bricks.Dense chromium oxide is formed by isostatic pressing. Its density is very high. The main technical indexes include Cr2O3 content >94%, porosity <15%, volume density >4.24g/cm3, and erosion loss only 1/10 of compact zirconia brick. Used in the E glass furnace unit kiln, directly contact high temperature molten glass melt, wall, melting parts, high temperature parts, pool bottom, main channel, pool wall and pool bottom, transition channel, pool wall, etc..

- Q: What are the refractory materials?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

- Q: Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

- Q: What kind of rock is corundum produced?

- Aluminum oxide (Al2O3) mineral. Due to Mohs hardness of up to 9, mainly used as high-grade abrasives. The crystal belongs to the three party system, a dolioform six square column, some are needle or plate. Aggregates are massive or columnar. Usually white, gray, yellow and other colors. If a small amount of Cr3+ is red, a ruby is called;

Send your message to us

Corundum Brick - Bonded Corundum Fire Brick Materials

- Loading Port:

- DALIAN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords