Corundum Mullite Insulating Brick for Ceramics Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mullite Insulating Brick,Mullite Corundum Brick for Ceramics Furnace Lining

Corundum bricks is widely used in oil gas gasifier, ethylene-generated furnace, and ammonia decomposing furnace in petrochemical industry, carbon black reactor in chemical industry, and high temperature kilns in refractories and ceramics industry.

Corundum bricks has gained the Third Prize of Science & Technology Progress from Sinopec and the former Ministry of Metallurgy Industry.

The brick has been used in the thermal equipment of domestric made or imported. It has been exported and used in German Texaco gasifier with good performance.

Product Applications:

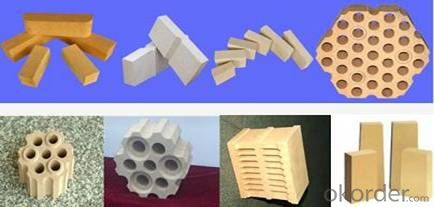

Corundum Mullite Brick are ideal for use in the below applications

Corundum mullite brick is mainly used as superstructure, feeder channel and cover plate in glass furnace. It can also be used as lining of high-temperature kiln and mesothermal carbon black reactor, the shed bar of kiln car, pusher plate of electronic magnetic material industry, etc.

Product Advantages:

CNBM has success in its Corundum Mullite Brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

1.High refractoriness under load

2.Excellent corrosion resistance to both acid and alkali

3.Good thermal shock stability

4.High density

5.Neutral material

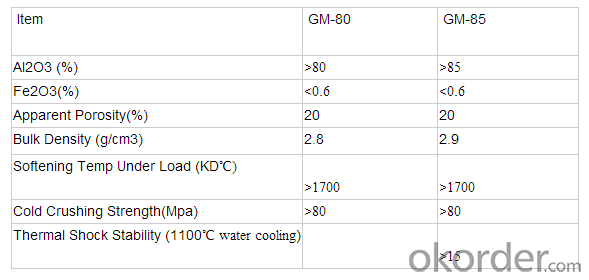

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

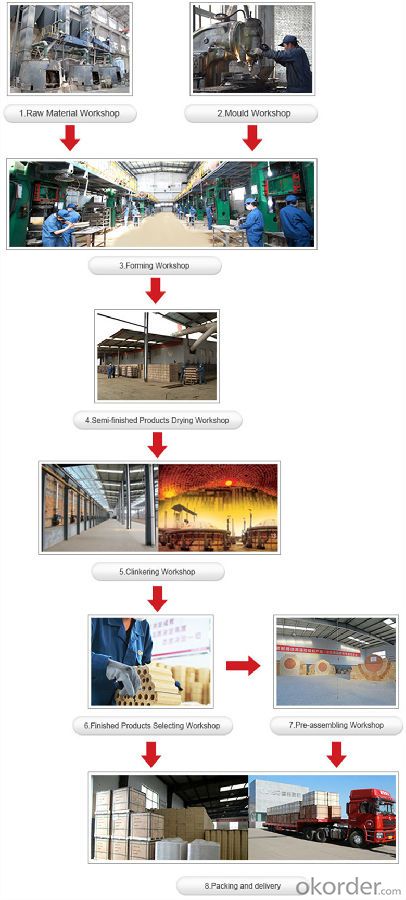

Produce Processing

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q: What is the main component of corundum?

- The name of corundum originates from India and is the name of mineralogy. There are three main variants of corundum Al2O3, which are alpha -Al2O3, beta -Al2O3 and gamma -Al2O3 respectively. Corundum is second only to diamond.

- Q: What material is used in an iron smelting furnace?

- Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on.

- Q: What are the advantages of refractories?

- The castable refractory is a refractory product with a certain shape after being melted at high temperature by a certain method. Neutral refractory is refractory material which is difficult to react with acid or alkaline slag at high temperature, such as carbon refractory and chrome refractory. Some of the high alumina refractories are also attributed to this category.

- Q: What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- The sinter plate dust collector is also called plastic plate dust collector. The utility model has the advantages that the utility model can adapt to various complicated working conditions, the dust removal rate is 99.99%, the utility model has the advantages of long service life, stable operation, high temperature resistance, and the utility model is a leading dedusting equipment in china.

- Q: What is the difference between corundum and high alumina?

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q: Ask for help about the phase of refractory material

- Secondary crystalline phase. The second phase and second phase or second phase, and the main crystal phase and is in high temperature liquid phase coexistence in refractory material, the number and influence on high temperature properties of materials is the main crystal phase is small second phases. As to the main crystalline phase of periclase magnesia chrome brick, magnesia brick, magnesia brick and magnesia calcium brick respectively containing Cr spinel, spinel, forsterite and calcium silicate two are secondary phase. There are structure of refractory refractory material in the crystal phase, especially the direct combination of high melting point and so on, the resistance to high temperature also tend to benefit. Compared with the ordinary brick, the second phase of the refractory products, make the products refractoriness under load are improved. Many according to mineral composition of refractory material named, such as mullite corundum brick, corundum mullite brick, is its main crystal phase and the second phase composite named. The former is mainly crystal phase, the latter is sub crystalline phase.

- Q: What kind of rock is corundum produced?

- Aluminum oxide (Al2O3) mineral. Due to Mohs hardness of up to 9, mainly used as high-grade abrasives. The crystal belongs to the three party system, a dolioform six square column, some are needle or plate. Aggregates are massive or columnar. Usually white, gray, yellow and other colors. If a small amount of Cr3+ is red, a ruby is called;

Send your message to us

Corundum Mullite Insulating Brick for Ceramics Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords