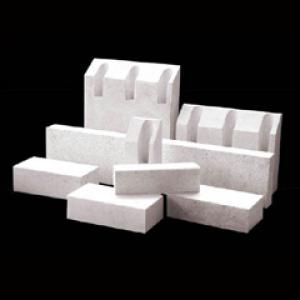

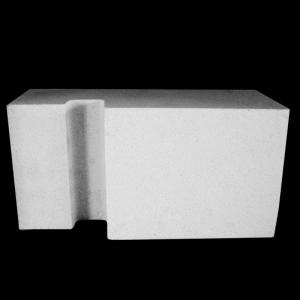

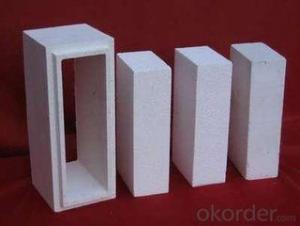

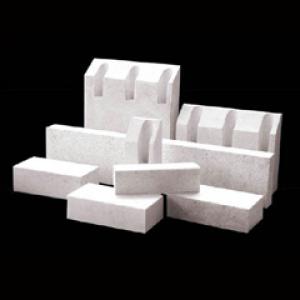

Corundum-Mullite Brick for Blast Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product features: the blast furnace by using artificial fused mullite brick fire and mullite as main raw materials, through high pressure molding, high temperature sintering, the main mineral composition of mullite, the product has low porosity, load softening point and high creep performance is good and excellent chemical corrosion resistance etc, is one of the big blast furnace in a high-level "ceramic cup" material, is also a hot blast stove and other industrial kiln with high-grade refractory materials.

|

- Q: Mullite bricks in alumina alumina is what?

- With mullite as main crystalline phase of high alumina refractory products. Mullite bricks containing Al2O3 64%~75%, refractoriness >1790? C, normal temperature compressive strength 70~260MPa, softening the starting point for 1600~1700 degrees. The manufacturing method for casting and sintering process.

- Q: What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity. Dongshin refractories manufacturers manufacturers supply, price is appropriate

- Q: Corrosion mechanism of iron on refractory materials

- Iron oxide can not be used as refractory,

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color. For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more

- Q: 2000 degree of high temperature materials, which belong to high temperature insulation materials?

- What can withstand 2000 degree high temperature materials on the market? What are the materials belong to high temperature materials? High temperature insulation material the most common are the following: calcium silicate shell, aluminum silicate cotton felt, glass surface, diatomite, vermiculite, foamed cement etc.. Among them, the first three are the most common, especially the aluminum silicate cotton felt, which can withstand 650 degrees of high temperature.

- Q: What material is heat insulated and not afraid of fire?

- Industrial production of perlite as insulation materials began in the United States in 1964Arizona, while China's expanded perlite began production in the late 60s. Expanded perlite includes perlite and pineRock and obsidian (three of which are close to the water content), due to the high temperature in 1000-1300C0, the volume of rapid expansion of 4 - 30 times, so collectively referred to as expanded perlite. Its characteristics are: low thermal conductivity, fire resistance and sound insulation performance is good, non-toxic, cheap, but have very strong water absorption, thermal conductivity due to water is much higher than that of pearlite, water will cause its insulation performance degradation, inorganic porous material, low strength, easy to break; therefore in thermal insulation applications when the need to enhance the hydrophobic and expanded perlite.

- Q: What are the high temperature insulation materials?

- If there is atmosphere protection, then graphite is a more powerful material. Melting point 3850 degrees Oh, almost all ultra high temperature kiln, can be protected by atmosphere, all with graphite material.

- Q: What kind of refractory material is used in the hearth of reverberatory furnace?

- The alumina fiber has a maximum resistance of 1700 degrees, and the zirconium fiber is generally 1700 to 2200 degrees

- Q: What material is good for refractory bricks?

- Is the main varieties of acidic silica brick, refractory brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

Send your message to us

Corundum-Mullite Brick for Blast Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords