Corundum Mullite Brick for High Temperature Industrial Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

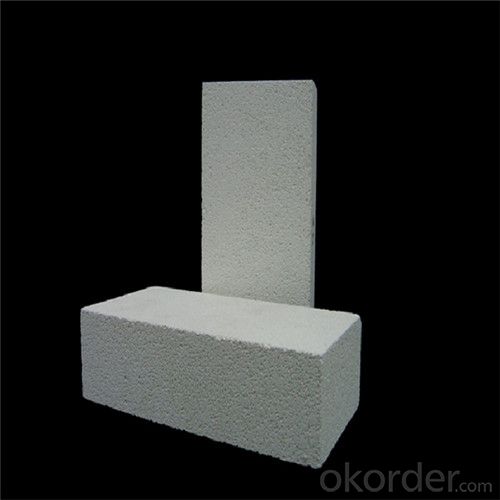

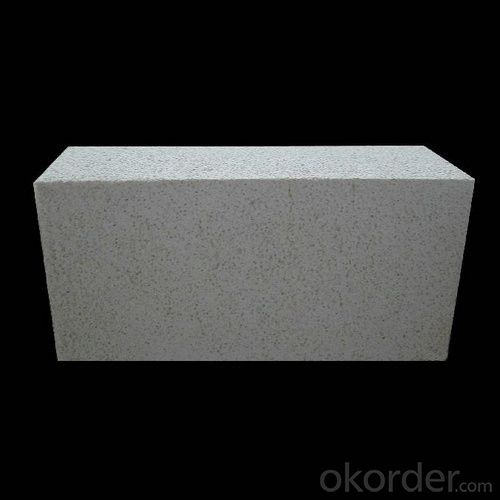

General Information of High Alumina Brick

CMAX high alumina firebricks are classified according to alumina content ranging from 48% to 90%.

Feature of High Alumina Brick

Low thermal conductivity

Excellent acid and base slagging resistance

CMAX high alumina bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

Image of High Alumina Brick

Technical Data of High Alumina Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervisor

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- In addition to AZS33# and AZS same co crystallization in vitro, 36#AZS due to the increase of chain like zirconia brick more crystals, while the glass phase content is low, so 36# AZS corrosion resistance has been further enhanced, so is suitable for the rapid flow of molten glass or high temperature region.AZS36 s is an excellent product in the AZS series. It has high resistance to glass liquid erosion and low pollution. It is usually used in the key parts of the glass furnace, such as the pool wall near the hot spot.

- Q: How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What are the advantages of refractories?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: What does refractory consist of?

- According to the shape of the product is shaped and unshaped refractory materials two categories, according to the chemical properties of acidic, neutral and alkaline refractory materials three categories, commonly used as refractory material of alkaline and neutral, such as magnesia, alkaline burned magnesia brick, magnesia chrome brick, magnesia calcium brick, high alumina brick, corundum neutral brick, clay brick, including: unshaped castable, ramming material, gunning material, coating material, dry vibration material etc..

- Q: Wave tile and throwing glaze, tile which good?

- The main advantages of all glazed glazed tiles are that they can be very rich and beautiful in texture and pattern, and they are suitable for family decoration, and can choose patterns according to their own family decoration style. Compared to the glazed tile, it has better pollutant discharge performance, and many pollutants are difficult to penetrate into it.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: What is the hardness of corundum refractory bricks?

- Corundum refractory brick has good stability against acid and alkaline slag, metal and glass solution. It can be used in oxidizing atmosphere at high temperature or in a reductive atmosphere. The basic material of corundum refractory brick is fused alumina or sintered corundum.

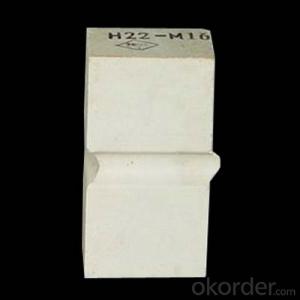

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

- Q: What kind of rock is corundum produced?

- Aluminum oxide (Al2O3) mineral. Due to Mohs hardness of up to 9, mainly used as high-grade abrasives. The crystal belongs to the three party system, a dolioform six square column, some are needle or plate. Aggregates are massive or columnar. Usually white, gray, yellow and other colors. If a small amount of Cr3+ is red, a ruby is called;

Send your message to us

Corundum Mullite Brick for High Temperature Industrial Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords