Low Cost_Various High Quality Equal / Unequal Steel Angle_Angle Steel_Angle Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Low Cost_Various High Quality Equal / Unequal Steel Angle_Angle Steel_Angle Bars

Detailed Informaion

Name | Equal/Unequal Angle Steel Bar |

Shape | Equal/Unequal Angle |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Quick Details

Standard:AISI,ASTM,BS,GB,JIS,EN

Size:45*30*4-200*125*18

Length: 6-16m

Technique: hot rolled

Grade:SS400, ST37-2, A36, S235JRG1, Q235, Q345 etc.

Type:EqualCertification:SGS,ISO

Inspection:accept BV SGS inspect

Specification

Specification | Weight | Specification | Weight |

Leg length*leg length*thickness |

| Leg length*leg length*thickness | (kg/m) |

(mm) | (kg/m) | (mm) |

|

25*25*3 | 1.124 | 90*90*8 | 10.946 |

25*25*4 | 1.459 | 90*90*10 | 13.476 |

30*30*3 | 1.373 | 100*100*6 | 9.366 |

30*30*4 | 1.786 | 100*100*7 | 10.83 |

40*40*3 | 1.852 | 100*100*8 | 12.276 |

40*40*4 | 2.422 | 100*100*10 | 15.12 |

40*40*5 | 2.976 | 100*100*12 | 17.898 |

45*45*3 | 2.088 | 110*110*7 | 11.928 |

45*45*4 | 2.736 | 110*110*8 | 13.532 |

45*45*5 | 3.369 | 110*110*10 | 16.69 |

50*50*3 | 2.332 | 110*110*12 | 19.782 |

50*50*4 | 3.059 | 125*125*8 | 15.504 |

50*50*5 | 3.77 | 125*125*10 | 19.133 |

50*50*6 | 4.465 | 125*125*12 | 22.696 |

63*63*5 | 4.822 | 125*125*14 | 26.193 |

63*63*6 | 5.721 | 140*140*10 | 21.488 |

63*63*8 | 7.469 | 140*140*12 | 25.522 |

70*70*5 | 5.397 | 140*140*14 | 29.49 |

70*70*6 | 6.406 | 160*160*10 | 24.729 |

70*70*7 | 7.398 | 160*160*12 | 29.391 |

70*70*8 | 8.373 | 160*160*14 | 33.987 |

75*75*5 | 5.818 | 160*160*16 | 38.518 |

75*75*6 | 6.905 | 180*180*12 | 33.159 |

75*75*7 | 7.976 | 180*180*14 | 38.383 |

75*75*8 | 9.03 | 180*180*16 | 43.542 |

75*75*10 | 11.089 | 180*180*18 | 48.634 |

80*80*6 | 7.376 | 200*200*14 | 42.894 |

80*80*7 | 8.525 | 200*200*16 | 48.68 |

80*80*8 | 9.658 | 200*200*18 | 54.401 |

80*80*10 | 11.874 | 200*200*20 | 60.056 |

90*90*6 | 8.35 | 200*200*24 | 71.168 |

90*90*7 | 9.656 |

|

|

Company Introduction

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

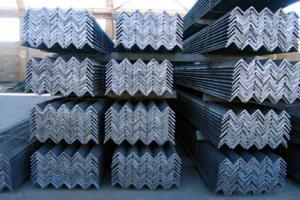

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different types of maraging steel?

- There are several different types of maraging steel, including Maraging 200, Maraging 250, Maraging 300, and Maraging 350. Each type has different composition and properties, but they all share the common characteristic of being a high-strength, low-alloy steel that can be heat treated to achieve exceptional strength and toughness.

- Q: How does special steel contribute to the tool manufacturing industry?

- Special steel plays a crucial role in the tool manufacturing industry as it offers several advantages that enhance the quality, performance, and durability of tools. Firstly, special steel is known for its exceptional strength and toughness, which makes it ideal for manufacturing high-quality tools that can withstand heavy usage and extreme conditions. In addition to strength, special steel also offers excellent wear resistance. Tools made from special steel can retain their sharpness and cutting edge for a longer period, reducing the need for frequent re-sharpening or replacement. This not only saves time and effort but also increases productivity in various industries that heavily rely on tools, such as construction, automotive, and aerospace. Moreover, special steel can be heat-treated to achieve specific properties, such as hardness, which is vital for tools like drills, saws, and blades. This heat treatment process allows manufacturers to tailor the steel's characteristics to meet the specific requirements of different tools, ensuring optimal performance and effectiveness. Special steel also provides corrosion resistance, an essential feature for tools that may be exposed to moisture, chemicals, or harsh environments. By preventing rust and corrosion, special steel helps to prolong the lifespan of tools, reducing maintenance costs and ensuring their reliable performance over time. Furthermore, the versatility of special steel allows manufacturers to create tools with complex shapes and designs. This flexibility opens up opportunities for innovation and the development of specialized tools that cater to unique applications and industries. Special steel can be easily machined, welded, and formed into various tool designs, enabling manufacturers to create efficient and ergonomic tools that offer improved handling and user comfort. In summary, special steel significantly contributes to the tool manufacturing industry by providing strength, wear resistance, heat treatability, corrosion resistance, and versatility. These properties enable the production of high-quality tools that are durable, reliable, and efficient, meeting the demands of diverse industries and enhancing productivity.

- Q: Can special steel be used in the textile industry?

- Yes, special steel can be used in the textile industry. Special steel, such as stainless steel, can be utilized in various textile machinery components like needles, pins, and cutting tools due to its durability, corrosion resistance, and high strength. Additionally, special steel wire can be used in weaving, knitting, and braiding processes to enhance the strength and performance of textile products.

- Q: How is special steel used in the medical industry?

- Special steel is used in the medical industry for a variety of applications. It is commonly used in the production of surgical instruments, implants, and medical devices due to its exceptional strength, durability, and resistance to corrosion. Special steel ensures that these instruments and implants can withstand the harsh conditions of medical procedures and maintain their integrity over time, ensuring better patient outcomes.

- Q: What are the applications of special steel in the automotive manufacturing process?

- Special steel is used in various applications within the automotive manufacturing process. It is commonly used for the production of engine components, such as crankshafts, camshafts, and connecting rods, due to its high strength, durability, and heat resistance. Special steel is also utilized in the manufacturing of suspension systems, steering components, and transmission parts, as it provides excellent fatigue resistance and wear properties. Additionally, special steel is employed for producing safety-related components like seat belt buckles and structural reinforcements, ensuring the overall safety and reliability of vehicles.

- Q: How does electrical steel contribute to the production of transformers and motors?

- Electrical steel, also known as silicon steel or lamination steel, plays a crucial role in the production of transformers and motors. Its unique magnetic properties make it an ideal material for the cores of these devices. The high silicon content in electrical steel reduces the energy losses that occur due to magnetic hysteresis and eddy currents, making the transformers and motors more efficient. Additionally, the laminated structure of electrical steel helps to minimize the eddy current losses further. Overall, the use of electrical steel in transformers and motors improves their performance, increases energy efficiency, and allows for compact and lightweight designs.

- Q: What are the different methods for improving the corrosion resistance of stainless special steel?

- There are several methods for improving the corrosion resistance of stainless special steel. Some of the common methods include alloying the steel with elements such as chromium, nickel, and molybdenum, which enhance its resistance to corrosion. Another method is passivation, which involves treating the steel with an acid solution to remove any surface contaminants and create a protective oxide layer. Coating the steel with materials like paint, powder coating, or electroplating can also improve its corrosion resistance. Additionally, proper cleaning and maintenance practices, such as regular removal of dirt and debris, can help prevent corrosion and maintain the steel's resistance over time.

- Q: How does special steel resist thermal fatigue?

- Special steel resists thermal fatigue due to its unique composition and structure. It is designed to have excellent thermal conductivity, allowing it to quickly dissipate heat and prevent the formation of thermal gradients within the material. This reduces the likelihood of cracking, deformation, or failure when exposed to rapid and repeated temperature fluctuations. Additionally, special steel undergoes specific heat treatment processes that enhance its resistance to thermal fatigue by improving its strength, toughness, and ability to withstand thermal shocks.

- Q: How does special steel resist fatigue?

- Special steel is designed to resist fatigue by incorporating specific properties that enhance its durability and strength. One of the primary factors that allows special steel to resist fatigue is its high tensile strength. This means that the steel can withstand large amounts of stress and load without deforming or breaking, which is crucial in preventing the initiation and propagation of fatigue cracks. Additionally, special steel often undergoes specific heat treatment processes, such as quenching and tempering, to further enhance its resistance to fatigue. This heat treatment modifies the microstructure of the steel, creating a fine and uniform grain structure that improves its mechanical properties. It increases the steel's hardness and toughness, making it less susceptible to fatigue failure. Furthermore, special steel can also contain alloying elements such as chromium, molybdenum, and vanadium, which contribute to its fatigue resistance. These alloying elements form carbides and other strengthening phases within the steel, resulting in improved hardness, strength, and resistance to fatigue crack propagation. Moreover, special steel can undergo specialized surface treatments, such as shot peening or nitriding. Shot peening bombards the steel surface with small metal particles, inducing compressive residual stresses. These compressive stresses counteract the tensile stresses that cause fatigue cracks, thus enhancing fatigue resistance. Nitriding involves diffusing nitrogen into the steel surface, creating a hardened layer that improves wear resistance and, consequently, fatigue resistance. In summary, special steel resists fatigue through a combination of factors, including high tensile strength, specific heat treatment processes, alloying elements, and specialized surface treatments. These properties work together to enhance the steel's durability, strength, and resistance to fatigue crack initiation and propagation, making it a reliable and long-lasting material in various applications.

- Q: What are the different aerospace grades of special steel?

- In the aerospace industry, various grades of special steel are commonly utilized to meet the stringent safety standards and high-performance requirements. These grades are specifically engineered for aerospace applications. Let's take a look at some of the different aerospace steel grades: 1. One of the steel grades, known as 300M, stands out for its exceptional strength and toughness. It finds frequent use in aircraft landing gears, structural components, and other demanding applications. 2. Another widely employed alloy steel in the aerospace sector is 4340. This steel grade boasts high strength and good hardenability, making it suitable for critical components such as gears and shafts. 3. Stainless steel grade 17-4 PH offers a unique combination of high strength, corrosion resistance, and good toughness. It is commonly found in aerospace applications, including aircraft engine components, landing gears, and structural parts. 4. Similarly, 15-5 PH stainless steel shares similarities with 17-4 PH in terms of high strength and corrosion resistance. It is often chosen for aerospace applications where weight reduction is crucial, such as aircraft structural components. 5. The 300 series stainless steels, such as grades 301, 302, and 304, are frequently employed in aerospace applications due to their excellent corrosion resistance, low magnetic permeability, and favorable strength-to-weight ratio. These steels find use in aircraft structures, fuel tanks, and components that face harsh environments. 6. Although not technically steel, titanium alloys are widely utilized in aerospace applications thanks to their exceptional strength, low density, and high corrosion resistance. Grades like Ti-6Al-4V are commonly employed in aircraft structures, engine components, and landing gears. These examples represent only a portion of the diverse aerospace grades of special steel used in the industry. Each grade possesses specific properties and characteristics that render them appropriate for various applications within the aerospace field.

Send your message to us

Low Cost_Various High Quality Equal / Unequal Steel Angle_Angle Steel_Angle Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords