40Cr / 41Cr4 / 5140 alloy steel specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

40Cr / 41Cr4 / 5140 alloy steel specifications

Product Description:

1. Standards

GB 40Cr, 40X, ASTM 5140, BS 520M40, JIS SCR440, NF 42C4, DIN 41Cr4(1.7035)

2. Size:

Round steel bar: Dia. 8-10000mm

Flat steel bar: 10-600*205*1500mm

Length: <12m

3. Machine Capability

Tensile strength (N/mm2Mpa): >=835

Elongation %: >=10

Yield strength: >=540

Hardness: HBS<=179

Reduction of area: >=40%

4. Machinability

Long, gummy chips characterize this alloys machinability. It can be machined in the annealed condition, however condition H1150M will yield best results. Post machining solution treatment of parts will be required prior to final hardening if machining in this condition.

5. Welding

Successfully welded by common fusion and resistance methods, this alloy should not be joined by oxyacetylene welding. AWS E/ER630 filler metal is recommended if required.

6. Process:

EAF+LF+VD+ Forged+ Heat Treatment (Annealed, A Normalized, Q+T)

7. Inspection

100% Ultrasonic according to the test standards: SEP1921-84, GR. 3 CLASS C/C

Chemical Composition:

Chemical Composition(for reference only) (%) | |||||||

C | Si | Mn | Cr | Ni | P | S | Cu |

0.37~0.44 | 0.17~0.37 | 0.50~0.80 | 0.8~1.1 | ≤ 0.03 | ≤ 0.035 | ≤ 0.035 | ≤ 0.30 |

Application:

(1) Generally used for producing the important parts with high strength and good plastic.

(2) After nitrogen treatment, used for producing the important parts with special performance

requirements, such as shafts, gears, fasteners, bolt of large dia steamer etc.

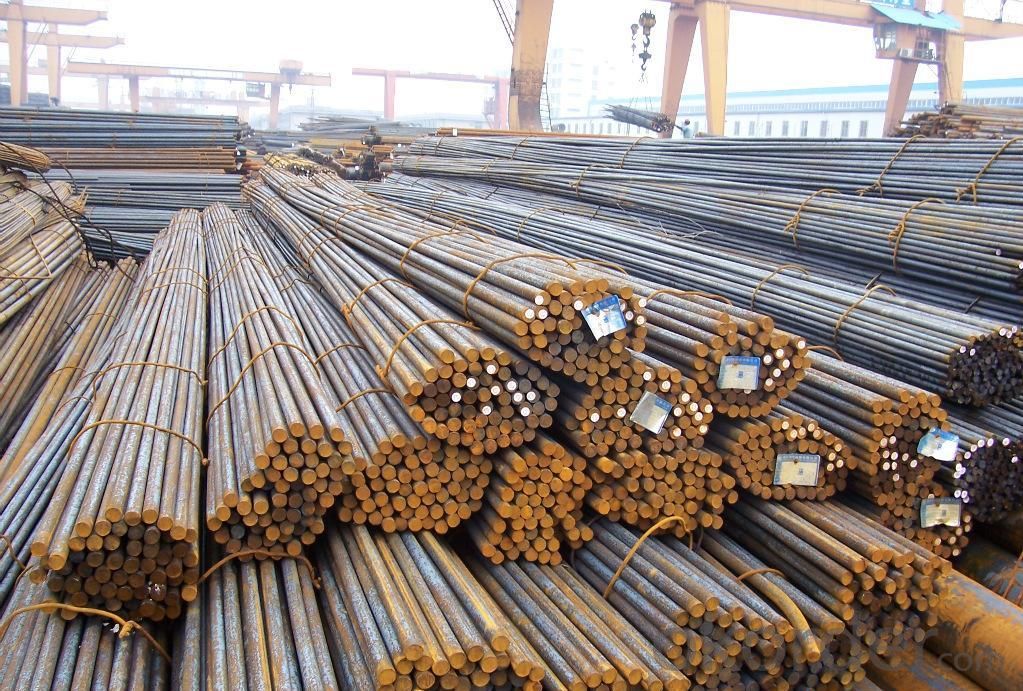

Product Show:

- Q: How does special steel perform in high-pressure applications?

- Special steel performs exceptionally well in high-pressure applications. Its unique properties, such as high strength, excellent corrosion resistance, and good thermal stability, make it an ideal choice for withstanding extreme pressure conditions. It maintains its structural integrity, preventing deformation or failure, even when exposed to intense pressure. Additionally, special steel's resistance to fatigue and wear ensures long-term performance and reliability in high-pressure environments.

- Q: How does special steel perform in terms of corrosion resistance in marine environments?

- Special steel alloys, specifically designed for marine environments, exhibit excellent corrosion resistance. Due to their higher levels of alloying elements like chromium, nickel, and molybdenum, these steels form a protective oxide layer that prevents rusting and pitting, even when exposed to saltwater and other harsh marine conditions. Their exceptional corrosion resistance ensures prolonged durability, reduced maintenance, and enhanced performance in marine environments.

- Q: How is special steel used in the production of turbine blades?

- Special steel is used in the production of turbine blades due to its exceptional properties such as high strength, corrosion resistance, and heat resistance. These blades must withstand extreme conditions, including high temperatures and pressures, as well as rotational forces. Special steel provides the necessary strength and durability to ensure the blades can effectively convert kinetic energy into mechanical power.

- Q: What are the different electrical grades of special steel?

- There exist various specialized types of steel that possess exceptional electrical properties. These types include: 1. Silicon Electrical Steel: This particular grade of steel contains a significant silicon content, typically ranging from 3% to 4%. The inclusion of silicon aids in minimizing eddy current losses and enhancing the steel's magnetic properties. Consequently, it becomes an ideal choice for utilization in electrical motors and transformers. 2. Stainless Electrical Steel: This specialized steel grade is crafted from stainless steel alloys, renowned for their remarkable resistance to corrosion. Additionally, stainless electrical steel exhibits low electrical resistivity and high thermal conductivity, making it well-suited for electrical connectors, terminals, and other components that necessitate excellent electrical conductivity and resistance to oxidation. 3. Tool Steel for Electrical Purposes: Tool steels are commonly employed in the production of various tools and dies. Certain tool steels are specifically engineered to possess enhanced electrical properties, including heightened electrical conductivity and resistance to heat. These grades are frequently utilized in the fabrication of electrical contacts, switches, and other electrical components that require exceptional resistance to wear and superior electrical performance. 4. Copper-Clad Steel for Electrical Applications: This specialized steel grade is created by bonding a layer of copper to a steel core. The copper layer offers outstanding electrical conductivity, while the steel core provides durability and strength. Electrical copper-clad steel is commonly employed in applications where high electrical conductivity is imperative, such as power transmission lines and grounding systems. In conclusion, the diverse electrical grades of specialized steel offer a variety of electrical properties to meet the specific requirements of various electrical applications. These grades are meticulously engineered to deliver optimal electrical performance, durability, and resistance to corrosion and wear.

- Q: How does special steel contribute to improving product lifespan?

- Special steel contributes to improving product lifespan by offering enhanced strength, durability, and resistance to corrosion. Its unique composition and manufacturing processes result in a material that can withstand harsh conditions, heavy loads, and wear and tear over an extended period. This increased longevity and reliability of products made with special steel ultimately leads to reduced maintenance costs, less frequent replacements, and improved customer satisfaction.

- Q: How does special steel perform in extreme cold temperatures?

- Special steel is custom-made to excel under frigid conditions, with alloys that possess a high level of low temperature ductility. This quality enables the steel to maintain its structural integrity even in the harshest cold settings, making it a popular choice in Arctic exploration, oil and gas operations in cold regions, and the aerospace industry. A key distinguishing feature of special steel is its resistance to brittleness when exposed to low temperatures. Unlike regular steel, which becomes brittle and susceptible to cracking in extreme cold, special steel retains its toughness, rendering it suitable for sub-zero conditions. This remarkable attribute is achieved through meticulous selection and control of the alloy's composition, allowing for a superior balance between strength and ductility. Moreover, special steel boasts exceptional resistance to corrosion, a particularly crucial trait in cold environments where exposure to snow, ice, and moisture is prevalent. The alloying elements present in special steel, such as chromium and nickel, generate a protective oxide layer on the surface, successfully preventing corrosion and preserving the steel's structural integrity. Additionally, special steel exhibits remarkable thermal conductivity, enabling efficient heat transfer even in extremely cold temperatures. This thermal property is of paramount importance in applications where effective heat management is essential, such as in the aerospace industry or in equipment operating in cold climates. In summary, special steel is meticulously engineered to excel in extreme cold temperatures. Its low temperature ductility, resistance to brittleness, corrosion resistance, and thermal conductivity establish it as a dependable and enduring material for diverse applications in cold environments.

- Q: What are the main characteristics of structural steel forgings?

- Structural steel forgings possess several key characteristics that make them ideal for various applications in construction and engineering. Firstly, one of the main characteristics of structural steel forgings is their exceptional strength and durability. Steel is known for its high tensile strength, which allows it to withstand heavy loads and resist deformation under stress. This makes structural steel forgings suitable for supporting large structures and withstanding dynamic forces such as wind or seismic activity. Another important characteristic is the versatility of structural steel forgings. Steel can be fabricated into a wide range of shapes and sizes, making it adaptable for different design requirements. It can be forged into complex shapes with intricate details, allowing for precise and customized components to be created. This versatility enables structural steel forgings to be used in a variety of applications, from beams and columns in buildings to bridges and offshore structures. Additionally, structural steel forgings have excellent weldability. Steel can be easily joined together using various welding techniques, allowing for the creation of strong and reliable connections. This enhances the overall structural integrity of steel components and ensures their longevity. Another key characteristic of structural steel forgings is their cost-effectiveness. Steel is one of the most economical construction materials due to its abundance, recyclability, and ease of manufacturing. The production process for steel forgings is efficient and can be scaled up to meet large-scale construction projects, making it a cost-effective choice for many applications. Furthermore, structural steel forgings are known for their resistance to corrosion. Steel can be treated with coatings or alloys to enhance its resistance to rust and other forms of corrosion. This makes it suitable for use in environments with high humidity, exposure to saltwater, or harsh weather conditions. In conclusion, the main characteristics of structural steel forgings are their exceptional strength, versatility, weldability, cost-effectiveness, and resistance to corrosion. These characteristics make structural steel forgings a preferred choice for various construction and engineering applications, providing durability, reliability, and longevity to structures.

- Q: How is precipitation-hardening steel used in the aerospace industry?

- Precipitation-hardening steel is commonly used in the aerospace industry due to its exceptional strength-to-weight ratio and high corrosion resistance. This type of steel undergoes a specialized heat treatment process that allows for the precipitation of particles within its microstructure, resulting in improved mechanical properties. These steels are used in various components and structures of aircraft, such as landing gears, engine parts, and structural frames, where strength, durability, and weight savings are crucial factors for performance and safety.

- Q: How does special steel contribute to the electrical industry?

- Special steel plays a crucial role in the electrical industry by contributing to the production of various components and equipment necessary for generating, transmitting, and distributing electricity. One important application of special steel in the electrical industry is in the manufacturing of power transformers. These transformers are essential for stepping up or stepping down the voltage levels in the electricity grid, enabling efficient transmission and distribution of electricity. Special steel, with its high strength, durability, and excellent magnetic properties, is used to construct the transformer cores. The high magnetic permeability of special steel ensures minimal energy loss during the transformation process, resulting in more efficient power transmission. Furthermore, special steel is also extensively used in the production of electrical conductors, such as wires and cables. These conductors are responsible for carrying electricity from power plants to various end-use applications. Special steel wires are known for their high conductivity and resistance to corrosion, making them ideal for transmitting electricity over long distances with minimal energy loss. Additionally, special steel is used in the manufacturing of electrical connectors and terminals, ensuring secure and reliable connections between different electrical components. In the electrical industry, special steel is also employed in the fabrication of electrical motors and generators. The high strength and magnetic properties of special steel contribute to the efficient conversion of electrical energy into mechanical energy, enabling the smooth operation of motors and generators. Moreover, special steel is used for manufacturing electrical switches, circuit breakers, and other protective devices, ensuring the safe and reliable functioning of electrical systems. Overall, special steel plays a vital role in the electrical industry by facilitating the production of essential components and equipment necessary for the generation, transmission, and distribution of electricity. Its unique properties contribute to improved energy efficiency, reliability, and safety in electrical systems, making it an indispensable material in this industry.

- Q: What are the properties of high-speed stainless steel?

- High-speed stainless steel possesses several properties that make it suitable for various applications. It has excellent hardness, wear resistance, and high strength at elevated temperatures. Additionally, it exhibits good corrosion resistance, high thermal conductivity, and retains its integrity even under extreme conditions. Its ability to maintain sharp cutting edges, combined with its high heat resistance, makes it ideal for use in cutting tools, drills, and machining applications.

Send your message to us

40Cr / 41Cr4 / 5140 alloy steel specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords