1080 Steel Round Bar from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1080 Steel Round Bar from CNBM

Product Description:

Diamater:Ø12mm-Ø650mm

Length: standard 6m,9m,12m, If you need special lengths,please call us.

Surface: Black, polished, grinded

Process:Hot rolled,cold drawn,forged

Inspection: UT test, mill test certificate, third party inspection such as SGS,BV etc.

Packing: In bundle, tied by steel straps, covered with protecting film

Use wooden box, fill with foam to keep the surface from damaging

Specification:

Specifications | Round bar | Diameter: 12mm~650mm |

Angle bar | Size: 3mm*20mm*20mm~12mm*800mm*800mm | |

Square/ bar | Size: 4mm*4mm~100mm*100mm | |

Flat bar | Thickness: 2mm~100mm | |

Width:10mm~500mm | ||

Hexagonal | Size: 4mm~800mm | |

Length | Standard 6m,9m,12m or as required. | |

Application:

Steel round bar is widely used for all general fabrication and repairs in industrial maintenance, agricultural implements, transportation equipment, ornamental work

frame work, braces, supports, shafts,axels,etc.

Hot rolled Steel round bars have a slightly grain textured finish.

Our service:

Our products mainly cover special steel,including stainless steel, tool steel, die steel,

bearing steel,etc. And in shapes, we provide steel round bar, steel square bar,steel

flat bar, steel plate, steel sheet, steel coil, steel wire, ans steel pipe.Being the top-class

products in China,our products have been used in all kinds of fields,such as aerospace,

electronic information, machine manufacture,petrochemical,automotive,communication,

transportation and medical instruments, etc. Our products are sold all over the world ,

mainly in Asia, South America, and Africa.

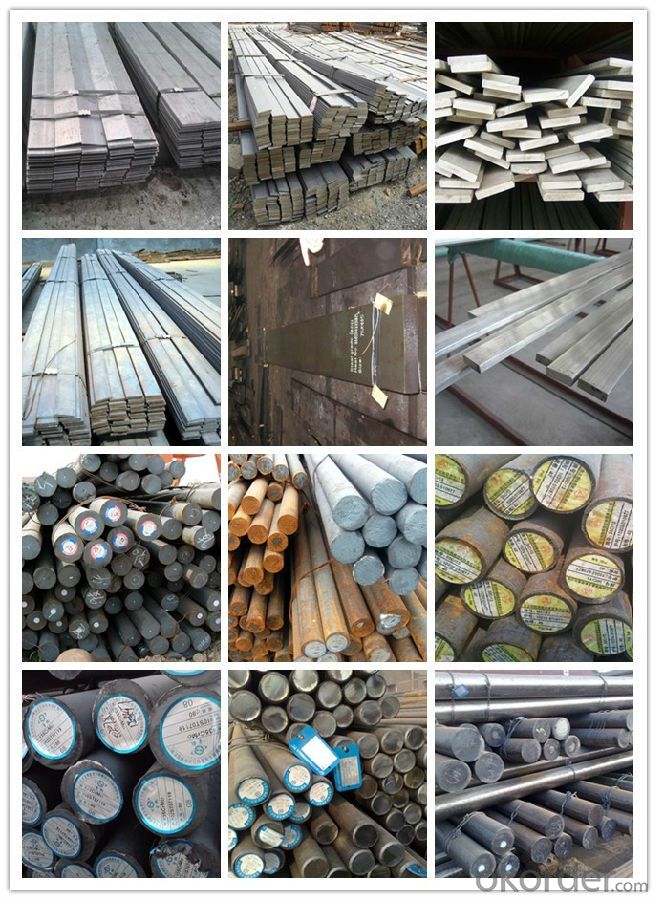

Product Show:

- Q:What are the common challenges in heat treatment of special steel?

- To achieve the desired material properties, careful attention must be given to several challenges encountered in the heat treatment of special steel. One primary challenge revolves around the necessity for meticulous temperature control throughout the heating and cooling stages. Special steels typically have specific temperature ranges for heat treatment that must be strictly adhered to in order to attain the desired microstructure and mechanical properties. Failing to maintain precise temperature control can result in inadequate or inconsistent heat treatment, ultimately leading to suboptimal material performance. Another challenge lies in the potential distortion or warping of the steel components during the heat treatment process. Special steels often possess intricate designs or complex shapes, making them more susceptible to distortion when subjected to high temperatures. This distortion can have adverse effects on the overall quality and dimensional accuracy of the final product. Consequently, careful consideration must be given to the selection of suitable heating and cooling methods, as well as the utilization of fixtures or jigs to minimize distortion. Moreover, special steels may contain alloying elements that significantly influence the heat treatment process. Elements like chromium, molybdenum, or vanadium can alter the steel's hardenability, tempering response, or transformation behavior. Their presence can introduce additional challenges when determining the optimal heat treatment parameters, necessitating adjustments to heating and cooling rates, soak times, or quenching media. Lastly, achieving uniformity in heat treatment across a batch of special steel components can prove to be challenging. Variations in size, shape, or composition within a batch can result in inconsistent heat treatment outcomes. Controlling the heating and cooling rates, ensuring proper circulation of the heat treatment media, and implementing effective process monitoring techniques are essential in achieving consistent and uniform material properties. In conclusion, the heat treatment of special steel encompasses challenges such as precise temperature control, distortion/warping, the influence of alloying elements, and achieving uniformity across a batch. Successfully addressing these challenges requires a comprehensive understanding of the steel's composition, meticulous process planning, and the utilization of appropriate process controls and monitoring techniques.

- Q:How does special steel contribute to product innovation?

- Special steel contributes to product innovation in several ways. Firstly, special steel offers enhanced mechanical properties such as high strength, hardness, and wear resistance. This allows designers and engineers to create innovative products that can withstand higher stresses, operate in extreme conditions, and have improved longevity. For example, special steel is commonly used in the aerospace industry to manufacture lightweight yet strong components that increase fuel efficiency and improve overall aircraft performance. Additionally, special steel can be tailored to have specific characteristics such as corrosion resistance, heat resistance, or magnetic properties. This enables the development of innovative products that can operate in challenging environments, such as marine structures, power plants, or electronic devices. For instance, special stainless steel alloys are extensively used in the medical field to produce implants and surgical instruments that are biocompatible, durable, and resistant to harsh sterilization processes. Furthermore, special steel can be manufactured with precise dimensions and tolerances, allowing for intricate and complex designs. This promotes product innovation by enabling the creation of intricate components, such as gears, bearings, or turbine blades, that require high precision and reliability. These advanced designs can improve the efficiency, performance, and overall functionality of various products, ranging from automotive engines to wind turbines. Moreover, the versatility of special steel enables it to be combined with other materials, such as polymers or composites, to create hybrid products with unique properties. This opens up possibilities for innovation in various industries, including automotive, construction, and consumer electronics. For example, special steel-reinforced concrete structures can be more robust and durable, while special steel-reinforced polymers can improve the strength and impact resistance of lightweight components. In conclusion, special steel contributes to product innovation by providing enhanced mechanical properties, tailored characteristics, precise dimensions, and the ability to be combined with other materials. These capabilities empower designers and engineers to create innovative products that have improved performance, durability, and functionality, leading to advancements in various industries.

- Q:How does free-cutting steel improve machinability?

- Free-cutting steel improves machinability by containing additional elements, such as sulfur, lead, or phosphorus, which help to break the chips and aid in chip removal during the machining process. These elements act as lubricants, reducing friction and heat generation, which results in improved surface finish and reduced tool wear.

- Q:How is high-temperature stainless steel used in the production of gas turbines?

- High-temperature stainless steel is used in the production of gas turbines due to its excellent heat resistance and corrosion properties. It is used to fabricate components such as combustion chambers, turbine blades, and exhaust systems, which are exposed to extreme temperatures and corrosive environments. The high-temperature stainless steel ensures the durability and efficiency of gas turbines, allowing them to operate at high temperatures without compromising performance or longevity.

- Q:How does special steel contribute to the electrical resistance of products?

- There are several ways in which special steel can contribute to the electrical resistance of products. To begin with, special steel can be customized in terms of its composition to possess specific electrical properties, such as resistivity. By carefully choosing the appropriate alloys and adjusting the carbon content, special steel can be made to have a higher resistivity compared to regular steel or other materials. This increased resistivity is advantageous in situations where electrical conductivity needs to be restricted. For instance, in electrical wiring, the utilization of special steel with higher resistivity can help prevent excessive current flow, thereby reducing the risk of overheating and potential electrical hazards. Similarly, in electrical resistors, special steel can be employed to achieve the desired level of resistance, allowing for controlled current flow and energy dissipation. Moreover, special steel can also contribute to electrical resistance through its physical properties. The microstructure of special steel can be engineered to enhance its resistance to the flow of electrical current. For example, the introduction of certain alloying elements or the implementation of specific heat treatment processes can generate a fine-grained structure or create barriers to the movement of electrons, ultimately increasing the overall resistance. Additionally, special steel finds application in the production of electrical contact materials. These materials must possess specific electrical and mechanical properties to ensure reliable and efficient electrical connections. Special steel alloys can offer high electrical conductivity while also exhibiting resistance to corrosion, wear, and deformation, thereby contributing to the overall electrical resistance of the product. In conclusion, special steel contributes to the electrical resistance of products through its tailor-made composition, which provides higher resistivity compared to regular steel. Furthermore, the microstructure of special steel can be modified to enhance its resistance to electrical current flow. Whether it is employed to limit current flow, control resistance, or create dependable electrical contacts, special steel plays a crucial role in a variety of electrical applications.

- Q:Can special steel be used in the battery manufacturing industry?

- Yes, special steel can be used in the battery manufacturing industry. Special steel, such as stainless steel or nickel-plated steel, can be used for battery casings, terminals, and other components due to its durability, corrosion resistance, and electrical conductivity properties.

- Q:How does special steel contribute to the oil and gas industry?

- Special steel plays a crucial role in the oil and gas industry by providing strength, corrosion resistance, and durability to equipment and infrastructure. It is used in the construction of pipelines, drill pipes, wellheads, valves, and various other components. The unique properties of special steel enable it to withstand harsh operating conditions, high pressures, and corrosive environments, ensuring the reliability and safety of oil and gas operations.

- Q:What are the requirements for special steel used in aerospace defense applications?

- The requirements for special steel used in aerospace defense applications include high strength, excellent corrosion resistance, heat resistance, and the ability to withstand extreme temperatures and pressure. It should also possess good weldability, fatigue resistance, and non-magnetic properties. Additionally, the steel should meet strict quality and certification standards to ensure reliability and safety in critical aerospace defense applications.

- Q:What are the specific requirements for special steel used in the railway sector?

- The specific requirements for special steel used in the railway sector are crucial for ensuring the safety, durability, and efficient operation of the railway infrastructure. Some of the key requirements include: 1. High strength: Special steel used in the railway sector must possess exceptional strength to withstand heavy loads, vibrations, and impacts. This is crucial for maintaining the structural integrity of tracks, bridges, and other components. 2. Wear resistance: Railway tracks and wheels experience significant wear due to continuous contact and friction. Special steel must have excellent wear resistance to minimize the need for frequent maintenance and replacement. 3. Fatigue resistance: The constant cyclic loading experienced by railway components demands high fatigue resistance in the steel. This allows them to withstand repetitive stress and prevents the occurrence of fatigue failures. 4. Corrosion resistance: Railway infrastructure is exposed to various environmental conditions, such as moisture, extreme temperatures, and chemicals. Special steel must possess good corrosion resistance to prevent rusting and degradation, ensuring a longer service life. 5. Heat resistance: In certain applications, such as rail joints and fasteners, special steel is subjected to high temperatures due to friction and stresses. The steel must have good heat resistance to maintain its mechanical properties under such conditions. 6. Weldability: Special steel used in the railway sector should have good weldability to enable efficient and reliable joining of components during manufacturing and maintenance processes. 7. Ductility and toughness: The steel must exhibit sufficient ductility and toughness to absorb energy and resist fracture in the event of a collision or impact, ensuring passenger safety. 8. Dimensional stability: Special steel used in the railway sector must maintain its dimensional stability under varying temperatures and loads to prevent deformation and ensure proper alignment of tracks and components. Meeting these specific requirements for special steel in the railway sector is essential for ensuring the safety, reliability, and longevity of railway infrastructure, contributing to the smooth operation of the entire transport network.

- Q:Can special steel be used in the production of springs for watches?

- Yes, special steel can be used in the production of springs for watches. Special steel, such as stainless steel or high carbon steel, is often preferred for watch springs due to its excellent strength, durability, and resistance to corrosion, ensuring reliable and long-lasting performance of the watch.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1080 Steel Round Bar from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords