440c Stainless Steel

440c Stainless Steel Related Searches

440 C Stainless Steel 440 Stainless Steel 440a Stainless Steel Stainless Steel 440 420c Stainless Steel 420hc Stainless Steel 400 Stainless Steel 430 Stainless Steel 440 Stainless Steel Sword 420 Stainless Steel Stainless Steel 430 403 Stainless Steel 400 Series Stainless Steel Stainless Steel 420 4 Stainless Steel 409 Stainless Steel A4 Stainless Steel 410 Stainless Steel 17 4 Stainless Steel 304l Stainless Steel 330 Stainless Steel Stainless Steel Hardware 400 Micron Stainless Steel Mesh White Stainless Steel Non Magnetic Stainless Steel 416r Stainless Steel 17 4ph Stainless Steel Stainless Steel Disc Stainless Steel Wall Ferritic Stainless Steel440c Stainless Steel Supplier & Manufacturer from China

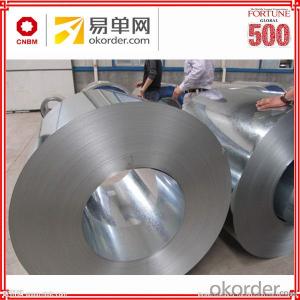

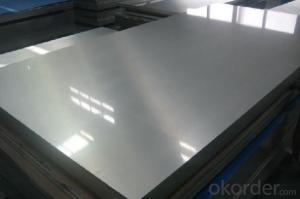

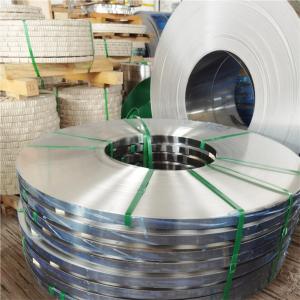

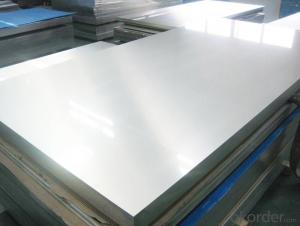

440c Stainless Steel is a high-quality material known for its excellent corrosion resistance and hardness, making it an ideal choice for various applications. This type of stainless steel is widely used in the manufacturing of knives, cutlery, and other precision tools that require a balance of strength and durability. Its properties also make it suitable for use in demanding environments, such as marine and industrial settings.The 440c Stainless Steel is utilized in a broad range of products, including kitchen knives, outdoor gear, and even some automotive components. Its ability to maintain a sharp edge and resist corrosion under harsh conditions has made it a popular choice among manufacturers and consumers alike. This material's versatility allows it to be used in both everyday items and specialized equipment, catering to a diverse set of needs.

Okorder.com is a leading wholesale supplier of 440c Stainless Steel, offering a vast inventory to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that their products meet the highest standards. Whether you are a manufacturer looking for bulk materials or a retailer seeking to stock up on high-quality items, Okorder.com is your go-to source for 440c Stainless Steel products.

Hot Products