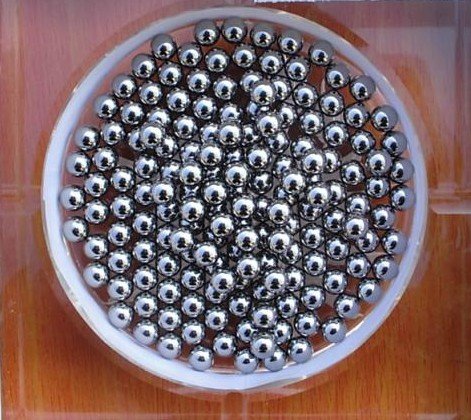

201 Stainless Steel Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Ball

MAIN PRODUCTS:

1. Material: AISI304, 316L, 420C, 430, 440C

2. Steel ball, with material AISI 1008-1086.

3. Chrome steel ball,with material: AISI52100

4. Flying saucer steel ball

5. Precision casting, including auto parts, machine parts, hardware handles, etc.

CHARACTER OF PRODUCTS:

1.The Grade of our products is from G10 to G1000

2.The dimension is from 0.5 mm to 25.4 mm.

3.The products from us are widely used in several industries, such as hardware, sliders, ball bearing lead screw, wheels, toys, bicycles, bearings, trust bearings pulleys, chemical industries, etc.

DETAIL SPECIFICATION:

|

Item |

SS304,316L,420C,440C Stainless steel ball |

|

Category |

Stainless Steel Ball |

|

Material |

AISI 420 430 440 SS304 316L |

|

Size |

0.5mm--25.4mm, 1/4",3/16",5/32",1/8",7/32",5/16",7/8",1" |

|

Grade |

G100-G3000 |

|

Hardness ( HRC) |

HRC58-65 |

|

Application |

Bicycle, bearing, pulley, slide, handcraft, shelf, luggage, hardware, grinding media |

|

Standard |

GB/T-308-2002, GB/T1148-93 |

|

Matched Standard |

DIN, JIS, ASME |

|

Certification |

ISO |

|

Packing |

Oily packing in pouch packing,plastic/tin box packing 1, 25kg/carton with steel pallet packing 2,25kg/carton without steel pallet packing 3,10kg/box then in wooden case packing 4,250kg/ steel drum packing or according to customers' requirement |

|

Place of original |

Shandong province, China |

|

Delivery |

Within 30 days or confirmed while placing order |

- Q: Can stainless steel balls be used in medical applications?

- Yes, stainless steel balls can be used in medical applications. Stainless steel is often chosen for medical devices due to its corrosion resistance, biocompatibility, and ability to withstand sterilization processes. It is commonly used in surgical instruments, implants, and other medical equipment.

- Q: Can stainless steel balls be used in fluid handling applications?

- Indeed, fluid handling applications can make use of stainless steel balls. Stainless steel, being a flexible material, boasts remarkable resistance against corrosion, rendering it suitable for deployment across diverse industries, particularly in fluid handling. Stainless steel balls exhibit the ability to endure exposure to a variety of fluids, such as water, chemicals, and corrosive substances, without experiencing deterioration or causing contamination. Frequently employed in valves, pumps, and other fluid handling machinery to regulate the movement and guarantee smooth functioning, stainless steel balls are additionally renowned for their durability, robustness, and minimal upkeep demands, thereby establishing themselves as a dependable option for fluid handling applications.

- Q: Are stainless steel balls resistant to chemicals or acids?

- Yes, stainless steel balls are generally resistant to most chemicals and acids. Stainless steel is a highly durable and corrosion-resistant material due to the presence of chromium, which forms a protective passive layer on its surface. This passive layer acts as a barrier, preventing the steel from reacting with chemicals and acids. However, it is important to note that the resistance of stainless steel balls to specific chemicals and acids can vary depending on the grade and composition of the steel. In some cases, certain types of acids or chemicals may still cause corrosion or damage to stainless steel balls, so it is advisable to consult the manufacturer or refer to specific chemical compatibility charts to ensure the suitability of stainless steel balls for a particular application.

- Q: How do stainless steel balls perform in radial loads?

- Known for their outstanding performance in radial loads are stainless steel balls. With their high strength and corrosion resistance, they possess the capability to endure heavy radial forces without deformation or breakage. Moreover, the sleek and polished surface of stainless steel balls aids in reducing friction and enabling seamless rotation, thereby enhancing their effectiveness in radial loads. Furthermore, stainless steel balls exhibit remarkable hardness, guaranteeing their longevity and durability in continuous applications involving radial loads. As a result, stainless steel balls are widely regarded as a dependable and efficient choice for handling radial loads, making them highly sought after in industries including automotive, aerospace, and manufacturing.

- Q: Are stainless steel balls resistant to rust or oxidation?

- Yes, stainless steel balls are resistant to rust and oxidation due to the high levels of chromium present in their composition, which forms a protective layer on the surface of the steel, preventing corrosion.

- Q: What are the different types of stainless steel ball float switches?

- In the market, one can find various types of stainless steel ball float switches. 1. Side-mount ball float switches: Installed on the side of a tank or vessel, these switches have a stainless steel float attached to a lever arm. This lever arm is connected to a switch mechanism, which is activated or deactivated by the movement of the float as the liquid level in the tank changes. 2. Top-mount ball float switches: These switches are placed on the top of a tank or vessel, with the stainless steel float hanging down into the liquid. Similar to side-mount switches, the float's movement triggers the switch depending on the liquid level. 3. Miniature ball float switches: These compact switches are ideal for limited space applications. They operate on the same principle as side-mount or top-mount switches but can be installed in tight spaces due to their small size. 4. High-temperature ball float switches: Stainless steel ball float switches can be designed to withstand high temperatures. These switches are constructed with materials that can handle elevated temperatures, making them suitable for applications where standard switches would not be able to function. 5. Explosion-proof ball float switches: These switches are specifically designed to be safe in hazardous environments where explosions may occur. They are made with materials and features that prevent sparks or ignition sources, ensuring the switch can be used safely in potentially dangerous settings. 6. Adjustable ball float switches: Some stainless steel ball float switches offer the flexibility of adjustable float positions. This allows users to set specific liquid level thresholds at which the switch will activate or deactivate, providing greater control over its operation. To ensure you select the most suitable stainless steel ball float switch for your needs, it is important to consider the specific requirements of your application and consult a knowledgeable supplier or manufacturer.

- Q: Can stainless steel balls be used in mining equipment?

- Yes, stainless steel balls can be used in mining equipment. Stainless steel is highly durable and resistant to corrosion, making it suitable for use in harsh mining environments. These balls are commonly used in grinding and crushing operations, where they help to break down ore and other materials. Stainless steel balls are also used in flotation processes, where they help separate valuable minerals from waste material. Additionally, stainless steel balls are used in conveyor systems and other equipment to facilitate the movement of materials within the mining operation. Overall, stainless steel balls are a reliable and effective component in mining equipment.

- Q: Can stainless steel balls be used in textile printing machines?

- Textile printing machines can indeed utilize stainless steel balls. Such balls are commonly employed in diverse industrial settings owing to their durability, resistance to corrosion, and capacity to endure high temperatures. Within textile printing machines, stainless steel balls may be employed in several components, including the rotary screen, squeegee, or ink roller. By facilitating seamless and effective movement, these balls guarantee accurate ink distribution and consistent printing outcomes. Furthermore, stainless steel balls are effortlessly cleaned and maintained, rendering them ideal for textile printing machines that necessitate frequent cleaning.

- Q: Can stainless steel balls be used in HVAC ductwork?

- Indeed, HVAC ductwork can make use of stainless steel balls. Stainless steel is frequently employed in HVAC systems because of its robustness, ability to resist corrosion, and high tolerance for elevated temperatures. Within ductwork, stainless steel balls find utility in a range of applications including dampers, louvers, and devices for air balancing. These balls are commonly utilized for regulating airflow, adjusting damper positions, or delivering a sealing function. Moreover, stainless steel balls are effortless to clean, maintain, and possess a lengthy lifespan, thereby rendering them highly suitable for incorporation into HVAC ductwork systems.

- Q: Can stainless steel balls be used in mechanical seals?

- Yes, stainless steel balls can be used in mechanical seals. Stainless steel is often chosen for its corrosion resistance and durability, making it an ideal material for various industrial applications, including mechanical seals. Stainless steel balls can effectively withstand high temperatures and pressures, ensuring a reliable and long-lasting performance in sealing applications. Additionally, stainless steel balls offer excellent wear resistance, reducing the risk of premature failure and increasing the lifespan of the mechanical seal. Overall, stainless steel balls are a popular choice for mechanical seals due to their excellent mechanical properties and resistance to corrosion.

1. Manufacturer Overview

| Location | Guangzhou,China |

| Year Established | 2001 |

| Annual Output Value | Above US$0.5 Million |

| Main Markets | Southeast Asia, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 10 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

201 Stainless Steel Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords