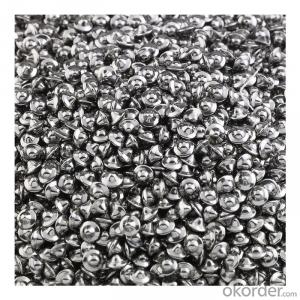

Stainless Steel Ball Stretcher

Stainless Steel Ball Stretcher Related Searches

Stainless Steel Ball Stainless Steel Balls Stainless Steel Ball Chain Stainless Steel Gazing Ball Stainless Steel Blender Stainless Steel Roller Stainless Steel Drawer Stainless Steel Cutter Stainless Steel Welder Stainless Steel Strainer Stainless Steel Basket Strainer Stainless Steel Strap Stainless Steel Scraper Stainless Steel Washer Stainless Steel Mixer Stainless Steel Tennis Chain Stainless Steel Degreaser Stainless Steel Heater Stainless Steel Trash Compactor Stainless Steel Drill Stainless Steel Ratchet Strap Stainless Steel Belt Stainless Steel Tube Cutter Stainless Steel Bread Maker Stainless Steel Solder Stainless Steel Diswasher Stainless Steel Scissor Stainless Steel Roaster Stainless Steel Percolator Stainless Steel SwivelStainless Steel Ball Stretcher Supplier & Manufacturer from China

Stainless Steel Ball Stretcher is a popular product designed for body modification enthusiasts, offering a safe and effective way to gradually stretch and enlarge the piercings in their genital area. Made from high-quality stainless steel, these stretchers are durable, hypoallergenic, and easy to clean, ensuring a comfortable and hygienic experience for the user.The Stainless Steel Ball Stretcher is widely used in various body modification scenarios, such as genital piercings, to help individuals achieve their desired aesthetic and size. It is essential to use this product responsibly and follow proper stretching guidelines to avoid injury or complications. The stretcher should be worn for short periods initially, gradually increasing the duration as the body adjusts to the new size. This product is ideal for those who have already healed piercings and are looking to enhance their appearance or comfort with larger jewelry.

Okorder.com is a reputable wholesale supplier of Stainless Steel Ball Stretcher products, boasting a vast inventory to cater to the needs of retailers and consumers alike. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Stainless Steel Ball Stretcher is manufactured to the highest standards, providing a reliable and safe option for body modification enthusiasts.

Hot Products