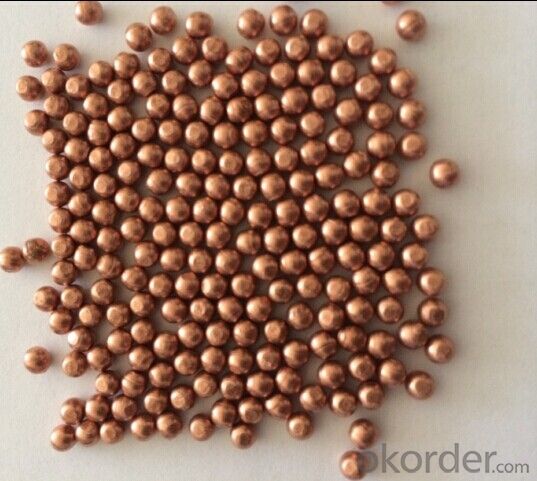

Grinding Ball Stainless Steel Ball Massage Ball Bearing Ball Steel Shot Valve Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product details:

Material : AISI420; AISI440C;304;316;316L; AISI210 etc

Grade: G10-G1000

Size: 1MM-60MM

1. AISI 420 Stainless Steel Ball

Magnetic, Harden-able,

fair corrosion resistance

used for special bearings and valves where

Balls requiring a combine -action of hardness and

corrosion resistance

2. AISI 440C Stainless Steel Ball

Magnetic, highest hardness,

good corrosion resistance

used in bearing nozzles and valves where

lubrication is poor or absent

3. AISI 304 Stainless Steel Ball

austentitic, corrosion resistance,

slightly magnetic, however annealing

can makes it non - magnetic

Used in valves and relevant application ,

food products, aerosols, home sprays,

perfumes and medical equipment.

4. AISI 316 Stainless Steel Ball

non - magnetic, good corrosion

resistance even when exposed to

marine atmosphere and sulfuric acid.

used in presence of sulphuric, phosphoric

and acetic acids.

Mainly used in chemical, paper and textile industries.

What can we do for you?

1) Chinese Professional Manufacturer for Steel Ball

2) Easy Storage

3) Factory Price & Best Quality

4) Accept Custom Order

5) Fast Delivery

6) OEM Service

7) Emergency Stocks

8) We promise all inquiry and emails will get our reply within 24 hours.

9) Convenient Payment:

T/T, 30% deposit, 70% before shippment; L/C at sight.; 100% Western Union in advance.

10) Professional production team, production line, experienced technical experts who engaged in steel balls for more than 20 years. We have the professional production line for steel balls.

- Q: What are the different types of steel tanks and their applications in the pharmaceutical industry?

- There are several types of steel tanks used in the pharmaceutical industry. These include stainless steel tanks, carbon steel tanks, and alloy steel tanks. Stainless steel tanks are commonly used for storing and mixing pharmaceutical ingredients due to their corrosion resistance and ease of cleaning. Carbon steel tanks, on the other hand, are often used for bulk storage of pharmaceutical products. Alloy steel tanks are typically used for specialized applications that require high strength and resistance to extreme temperatures. Overall, steel tanks play a crucial role in maintaining the integrity and quality of pharmaceutical products throughout their production and storage processes.

- Q: How is steel used in the construction of railway stations and terminals?

- Steel is a crucial material in the construction of railway stations and terminals as it is used for various structural components such as beams, columns, and trusses, providing strength and stability to the buildings. It is also used in the fabrication of platforms, staircases, and canopies, ensuring durability and safety for passengers and staff. Moreover, steel is employed in the construction of railway tracks and platforms, providing a sturdy foundation for the movement of trains and facilitating efficient transportation.

- Q: How is steel used in the construction of warehouses and storage facilities?

- Steel is commonly used in the construction of warehouses and storage facilities due to its strength and durability. It is used for the framework and support structures, as well as for roofing and siding. Steel provides a secure and reliable structure that can withstand heavy loads and harsh weather conditions, making it ideal for these types of buildings.

- Q: What are the different types of steel scaffolding systems?

- There are several types of steel scaffolding systems, including tube and coupler scaffolding, system scaffolding, and frame scaffolding. Tube and coupler scaffolding consists of tubes and couplers that are connected together to form a stable structure. System scaffolding uses pre-designed components that can be easily assembled and dismantled, providing flexibility and efficiency. Frame scaffolding is made up of frames and cross braces, offering a simple and sturdy solution for construction projects.

- Q: What are the factors that affect the price of steel products?

- There are several factors that can influence the price of steel products, including the cost of raw materials, such as iron ore and coal, which are used in the manufacturing process. Additionally, fluctuations in global supply and demand, changes in government policies and regulations, currency exchange rates, and overall economic conditions can also impact steel prices. Other factors that may affect the price include transportation costs, energy prices, and the level of competition within the steel industry.

- Q: What are the different types of steel gratings and their applications?

- There are several types of steel gratings that serve different purposes and applications. These include welded steel gratings, press-locked steel gratings, riveted steel gratings, and heavy-duty steel gratings. Welded steel gratings are commonly used in industrial platforms, walkways, and stair treads due to their strong and durable construction. Press-locked steel gratings are versatile and ideal for architectural applications like facades, fences, and sunshades. Riveted steel gratings are suitable for heavy-load areas such as bridges and vehicle ramps, as they offer high strength and stability. Heavy-duty steel gratings are designed for extreme conditions and heavy loads, making them perfect for areas like airports, docks, and industrial plants. These gratings provide superior strength and durability to withstand intense pressure and impact. Overall, the different types of steel gratings cater to various industry requirements, ensuring safety, stability, and functionality in a wide range of applications.

- Q: How does the quality of steel affect its performance?

- The quality of steel directly impacts its performance. Higher-quality steel possesses superior strength, durability, and resistance to wear and tear. It also exhibits better heat conductivity and corrosion resistance, making it more suitable for various applications. Conversely, lower-quality steel may be more prone to breakage, deformation, and rapid deterioration, resulting in compromised performance and potentially unsafe conditions.

- Q: What are the common uses of steel in the mining industry?

- Steel is commonly used in the mining industry for various purposes such as construction of mining equipment, infrastructure, and vehicles. It is also used in the production of drill bits, conveyor belts, and crushers. Additionally, steel is essential for creating support structures, including mine shafts and tunnels, due to its strength and durability.

- Q: How do steel products contribute to the construction of theme-based water parks?

- Steel products play a crucial role in the construction of theme-based water parks. They are used in various structural and architectural components, such as roller coaster tracks, water slides, support beams, and framework for buildings and attractions. The strength and durability of steel ensure the safety and stability of these structures, allowing for thrilling rides and unique water features. Additionally, steel can be shaped and molded into intricate designs, enhancing the aesthetic appeal of the park and creating a visually captivating experience for visitors.

- Q: What are the different types of steel plates and their uses?

- There are several different types of steel plates, each with their own unique properties and uses. Some common types include carbon steel plates, which are versatile and used in a wide range of applications such as structural components and machinery parts. Stainless steel plates are corrosion-resistant and commonly used in food processing equipment, medical instruments, and construction projects. High-strength low-alloy (HSLA) steel plates are durable and used in heavy machinery and transportation equipment. Abrasion-resistant steel plates are designed to withstand wear and tear, making them suitable for applications like mining equipment and bulldozer blades. The specific type of steel plate chosen will depend on the desired characteristics and the intended use.

Send your message to us

Grinding Ball Stainless Steel Ball Massage Ball Bearing Ball Steel Shot Valve Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords