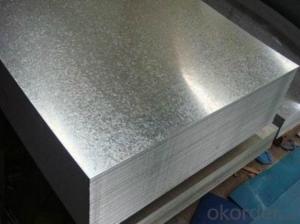

Best Quality for Regular Spangle Hot Dipped Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification of Hot Dip Galvanized Steel Coil:

1. Thickness: 0.13mm-0.7mm

2. Width: 600mm-1250mm

3. Zinc Coating: 30-200g/m2

4. Internal Diameter: 508mm/610mm

5. Coil Weight: 3-12MT

6. Quality: commercial and structural quality

7. Surface Treatment: regular & minimum spangle, zero spangle, oiled & dry , chromated , non-skin pass ,skin pass

8. Standard: JIS G 3302, ASTM A 653M, EN 10327

9. Steel Grade: SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD

Technical Data of Hot Dip Galvanized Steel Coil

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Technical Data | |

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Out-of-square | not exceed 1% Flatness |

Bow | 15mmmax |

Edge Wave | 9mmmax |

Centre Buckle | 8mmmax |

Bending At 180 Degree | No crack, purling and fraction |

Application of Hot Dip Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

Package of Hot Dip Galvanized Steel Coil

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips.

- Q: What are the advantages of using steel in the manufacturing of security doors and windows?

- The advantages of using steel in the manufacturing of security doors and windows include its high strength and durability, which provides excellent protection against forced entry. Additionally, steel is resistant to fire, corrosion, and extreme weather conditions, making it a reliable choice for long-lasting security solutions. Furthermore, steel's rigidity allows for the design of intricate locking mechanisms and reinforced frames, enhancing the overall security level.

- Q: How is steel used in the manufacturing of mining equipment?

- Steel is used in the manufacturing of mining equipment due to its strength, durability, and resistance to wear and tear. It is commonly used to make various components such as frames, buckets, drill bits, and crushers, which need to withstand the harsh conditions of mining operations.

- Q: How is steel used in the construction of convention centers and exhibition halls?

- Steel is commonly used in the construction of convention centers and exhibition halls due to its strength and versatility. It is used to create the structural framework and support systems, including columns, beams, and trusses. Steel's high strength-to-weight ratio allows for spacious, open interiors without the need for excessive supporting columns. Additionally, its durability and resistance to fire and corrosion make it an ideal choice for these large-scale structures, ensuring long-term stability and safety.

- Q: How does steel reinforcement work in concrete structures?

- Steel reinforcement works in concrete structures by providing additional strength and flexibility to the concrete. The steel bars, also known as rebar, are placed within the concrete before it sets, forming a strong bond between the two materials. This reinforcement helps to distribute the load evenly and prevent cracking or failure under heavy loads or external forces. The combination of concrete and steel creates a durable and long-lasting structure that can withstand the stresses and pressures it may encounter over time.

- Q: How does the price of steel products vary based on their composition and quality?

- The price of steel products can vary based on their composition and quality as different elements and alloys added to steel can affect its properties and performance. Higher-quality steel products, which are often made using premium alloys and have undergone rigorous testing and quality control measures, tend to be more expensive. Similarly, steel products with specific compositions tailored for certain applications, such as stainless steel for corrosion resistance or high-strength steel for structural purposes, may have higher prices due to the additional manufacturing processes and materials involved. Ultimately, the price of steel products is influenced by the raw materials used, manufacturing techniques, quality standards, and market demand for specific compositions and qualities.

- Q: What are the different types of steel forgings and their applications in the construction of power transmission lines?

- There are several types of steel forgings commonly used in the construction of power transmission lines. One type is the anchor forging, which is used to securely anchor the transmission towers to the ground. Another type is the crossarm forging, which provides support for the power lines and insulators. Additionally, there are pole line hardware forgings that are used for attaching the power lines to the transmission towers. These forgings are crucial for ensuring the structural integrity and stability of the power transmission lines, allowing for the efficient and reliable distribution of electrical power.

- Q: What are the different types of steel fasteners and connectors available?

- There are several types of steel fasteners and connectors available, including screws, bolts, nuts, washers, anchors, rivets, and clips. Each type has its own specific application and is designed to provide secure and reliable connections in various construction and manufacturing industries.

- Q: How does steel pipe coating for oil pipelines work?

- Steel pipe coating for oil pipelines works by applying a protective layer on the exterior surface of the steel pipe to prevent corrosion and damage. The coating, typically made of epoxy, polyethylene, or polyurethane, creates a barrier between the pipe and the surrounding environment, preventing contact with moisture, chemicals, and other corrosive agents. This coating process involves surface preparation, which includes cleaning, blasting, and priming the pipe, followed by the application of the coating material through various methods like spraying or wrapping. The coating not only enhances the durability and lifespan of the pipeline but also ensures the safe transportation of oil by minimizing the risk of leaks and structural failures.

- Q: What are the properties and characteristics of stainless steel?

- Stainless steel is a versatile and durable material known for its excellent corrosion resistance. It contains a minimum of 10.5% chromium, which forms a thin, protective oxide layer on its surface, preventing rust and staining. This oxide layer is self-repairing, which helps maintain the material's integrity over time. Some key properties of stainless steel include its high strength, heat resistance, and low maintenance requirements. It is also non-magnetic and has good formability, making it suitable for various applications. Stainless steel is available in different grades, each with specific compositions and properties tailored for different uses, such as food processing, construction, automotive, and medical equipment. Overall, its combination of strength, corrosion resistance, and versatility makes stainless steel a widely used and sought-after material in many industries.

- Q: What is the process of steel galvanization?

- The process of steel galvanization involves immersing the steel in a bath of molten zinc or applying a zinc coating to the steel through a hot-dip or electroplating method. This forms a protective layer of zinc on the surface of the steel, preventing rust and corrosion and increasing its durability.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Regular Spangle Hot Dipped Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords