Cold Rolled C Channel with High Quality C140/C160

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Cold Rolled C Channel with High Quality C140/C160:

1.Our Cold Rolled C Channel with High Quality C140/C160 has lots of advantages, just as followings:

a) At reasonable price and good quality.

b) To be convenient in construction and to save much time and labor.

c) The length of Cold Rolled C Channel can be manufactured according to customer’s requirements.

d) The Cold Rolled C Channel has strong mechanical strength.

e). The Cold Rolled C Channel possesses various kind of fittings, through which it is suitbal for many combinations.

The detailed sections of Cold Rolled C Channel with High Quality C140/C160 as per GB standard:

| Model | Section size | |||

| h(mm) | b(mm) | a(mm) | s(mm) | |

| C140 | 140 | 50 | 20 | 1.6-3.2 |

| C140 | 140 | 60 | 20 | 1.6-3.2 |

| C160 | 160 | 50 | 20 | 1.6-3.2 |

The mechanical property of MS Cold Rolled C Channel with High Quality C140/C160 according to Q235B:

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 months from the beginning of production.

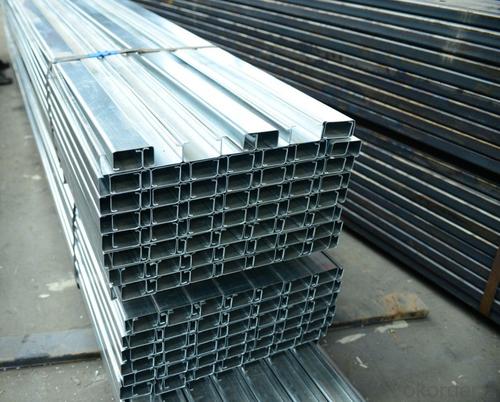

Images of Cold Rolled C Channel with High Quality C140/C160:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: How is steel made and processed to create various steel products?

- Steel is made through a process called steelmaking, which involves melting iron ore in a furnace and adding various alloying elements to enhance its properties. Once the molten steel is formed, it is then processed through techniques like casting, rolling, forging, or extrusion to create a wide range of steel products such as sheets, bars, pipes, or structural components. These processes help shape the steel into the desired form, size, and strength, ensuring that it can be used in various industries like construction, automotive, or manufacturing.

- Q: What are the different types of steel fencing and barriers available?

- There are various types of steel fencing and barriers available, including chain link fences, wrought iron fences, steel picket fences, steel mesh fences, and steel bollards. Each type offers unique features and benefits, catering to different security and aesthetic requirements.

- Q: What are the different types of surface finishes for steel products?

- There are several different types of surface finishes for steel products, including mill finish, brushed finish, polished finish, galvanized finish, and powder coated finish.

- Q: How are steel tubes used in the fabrication of hydraulic systems?

- Steel tubes are used in the fabrication of hydraulic systems as they provide a strong and durable material that can withstand high pressure and harsh conditions. These tubes are commonly used to transport hydraulic fluids, such as oil or water, from one component to another within the system. They ensure efficient and reliable flow of fluids, maintaining the system's functionality and performance. Additionally, steel tubes can be bent, cut, and welded into various shapes and sizes, allowing for customization and easy installation in hydraulic systems.

- Q: What are the different types of steel rails and their applications in railways?

- There are several types of steel rails used in railways, including plain carbon steel rails, heat-treated carbon steel rails, and alloy steel rails. Plain carbon steel rails are the most commonly used type and are suitable for most railway applications. They have good strength, durability, and wear resistance. Heat-treated carbon steel rails undergo a heat treatment process to improve their hardness and strength. These rails are used in high-traffic areas, such as mainline tracks, where they can withstand heavy loads and minimize wear. Alloy steel rails contain additional elements like manganese, chromium, and nickel, which enhance their strength and corrosion resistance. These rails are used in harsh environments, such as coastal areas, where there is a higher risk of corrosion. The choice of steel rail depends on factors like the railway's traffic volume, speed, and environmental conditions. By selecting the appropriate type of steel rail, railways can ensure safety, reliability, and longevity of their tracks.

- Q: What are the different types of steel valves?

- There are several types of steel valves, including gate valves, globe valves, ball valves, check valves, butterfly valves, and needle valves. Each type has its own unique design and functionality, catering to specific applications and industries.

- Q: What are the different types of steel products used in the oil and gas industry?

- There are several types of steel products used in the oil and gas industry, including pipes, tubing, casings, and fittings. These products are commonly made from carbon steel, alloy steel, or stainless steel, depending on the specific application and requirements. Carbon steel is often used for general-purpose applications, while alloy steel is preferred for more demanding conditions such as high-pressure or high-temperature environments. Stainless steel is chosen for its corrosion resistance in aggressive or corrosive environments.

- Q: How is steel used in the construction of hospitals and healthcare facilities?

- Steel is an essential material in the construction of hospitals and healthcare facilities due to its strength, durability, and versatility. It is commonly used for structural purposes, such as beams, columns, and frames, providing a solid and sturdy framework for the buildings. Steel is also used in the construction of walls, roofs, and floors, ensuring stability and safety. Additionally, steel is often used for medical equipment and fixtures, as it can be easily shaped and fabricated to meet specific requirements. Overall, steel plays a crucial role in ensuring the structural integrity and functionality of healthcare facilities.

- Q: What are the different types of steel sheet and their uses?

- There are several types of steel sheets, including hot rolled, cold rolled, galvanized, and stainless steel sheets. Hot rolled sheets are commonly used in construction, fabrication, and general manufacturing due to their strength and malleability. Cold rolled sheets are often used for applications requiring precise dimensions and a smooth surface finish, such as automotive body panels or appliances. Galvanized sheets have a protective zinc coating and are widely used in outdoor applications to prevent corrosion, such as roofing or fencing. Stainless steel sheets, known for their resistance to corrosion and high strength, are commonly used in industries like food processing, medical equipment, and architectural design.

- Q: What are the different types of steel products used in the manufacturing of kitchen appliances?

- There are various types of steel products used in the manufacturing of kitchen appliances, including stainless steel, carbon steel, and galvanized steel. Stainless steel is the most common choice due to its durability, resistance to corrosion, and aesthetic appeal. Carbon steel is often used for cookware due to its excellent heat distribution and retention properties. Galvanized steel, on the other hand, is primarily used for the external components of kitchen appliances, providing strength and protection against rust.

Send your message to us

Cold Rolled C Channel with High Quality C140/C160

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords