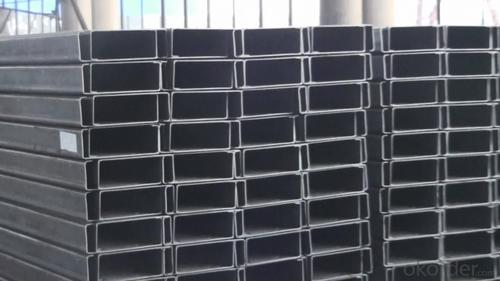

Cold Rolled C Channel

- Loading Port:

- Tianjin Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Tons m.t.

- Supply Capability:

- 1000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Cold Rolled C Channel:

1.Our Cold Rolled C Channel has lots of advantages, just as followings:

a) At reasonable price and good quality.

b) To be convenient in construction and to save much time and labor.

c) The length of Cold Rolled C Channel can be manufactured according to customer’s requirements.

d) The Cold Rolled C Channel has strong mechanical strength.

e). The Cold Rolled C Channel possesses various kind of fittings, through which it is suitbal for many combinations.

f) Our Cold Rolled C Channel is attractive in appearance as well as beautiful in design

g) Free from slotted punching

2. The detailed sections of our Cold Rolled C Channel can be found in table-1

Size | Weight(kg/m) | Size | Weight(kg/m) |

80×40×20×2.5 | 3.925 | 180×60×20×3 | 8.007 |

80×40×20×3 | 4.71 | 180×70×20×2.5 | 7.065 |

100×50×20×2.5 | 4.71 | 180×70×20×3 | 8.478 |

100×50×20×3 | 5.652 | 200×50×20×2.5 | 6.673 |

120×50×20×2.5 | 5.103 | 200×50×20×3 | 8.007 |

120×50×20×3 | 6.123 | 200×60×20×2.5 | 7.065 |

120×60×20×2.5 | 5.495 | 200×60×20×3 | 8.478 |

Table-1

Note: we are definitely good at manufacturing and supplying Cold Rolled C Channel as per S235JR. Also, we are willing and able to provide our customers Cold Rolled C Channel in other sizes, which depends on customers’ concret requirements for the quantity.

3. The chemical composition of Cold Rolled C Channel as per S235JR is shown in the table-2

Alloy No | Element(%) | ||||

C | Mn | S | P | Si | |

S235JR | 0.12—0.20 | 0.3—0.7 | ≤0.030 | ≤0.030 | ≤0.20 |

Table-2

4. The mechanical property of Cold Rolled C Channel as per S235JR is shown in the table-3-1 and table-3-2

Alloy No | Yielding strength point( Mpa) | |||

Thickness (mm) | ||||

≤16 | >16--40 | >40--60 | >60--100 | |

≥ | ||||

S235JR | 235 | 225 | 215 | 195 |

Table-3-1

Alloy No | Tensile strength (Mpa) | Elongation after fracture(%) | |||

Thickness (mm) | |||||

| ≤16 | >16--40 | >40--60 | >60--100 | |

≥ | |||||

S235JR | 340--510 | 24 | 23 | 22 | 27 |

Table-3-2

Applications of Cold Rolled C Channel:

The Cold Rolled C Channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc.The hot rolled channel steel belongs to carbon structural steel which is applied to in the field of construction and machinery.In details, the hot rolled channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the hot rolled channel steel we supply must possess perfect welding property, riveting property and mechanical property and so on.

Package & Delivery of Cold Rolled C Channel:

1.The channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

2. And the channel steel could be loaded into 20ft or 40ft container, or by bulk cargo.If the weight of each bundle reaches more than 3.5 mt, the loading by break bulk cargo should be choosed.When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

3.As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4.All in all, we could do in accordance with customer's request.

Production Flow of Cold Rolled C Channel:

1.The steel billet shall be heated in the high temperature furnace.

2. The heated steel billet shall be rolled five to nine times with the aim of shaping the general figure of steel u channel.

3. The rolled steel u channel should be put onto the cooling bed to make the temperature low.

4. The steel u channel should be straighted on the straightener.

5. The straighted steel u channel will be cut into meters by saw, as per customer's requirements.

6. At the last part of production, the channel steel must be tested in order to confirm that the finished products are completely free from crack, pore, slag, scab or fold on the surface.

- Q: Can steel channels be used for solar panel mounting?

- Yes, steel channels can be used for solar panel mounting. Steel channels provide a strong and durable option for mounting solar panels, as they are capable of supporting the weight of the panels and withstanding various weather conditions. Additionally, steel channels can be easily customized and adjusted to fit the specific requirements of the solar panel installation. They offer a secure foundation for the panels and can be installed on rooftops, ground mounts, or other structures. However, it is important to ensure that the steel channels are properly installed and anchored to provide the necessary stability for the solar panels.

- Q: Can steel channels be used for supporting curtain wall systems?

- Yes, steel channels can be used for supporting curtain wall systems. Steel channels are commonly used for structural support in construction and can provide the necessary strength and stability required to support the weight of curtain wall systems. Additionally, steel channels can be easily customized and fabricated to accommodate the specific design requirements of the curtain wall system. They can be attached to the building structure and provide a secure anchor point for the curtain wall system, ensuring its stability and performance. Overall, steel channels are a popular choice for supporting curtain wall systems due to their strength, durability, and versatility.

- Q: Can steel channels be welded together?

- Certainly, it is feasible to weld steel channels together. Welding serves as a prevalent technique in order to unite steel channels, thus establishing a robust and long-lasting connection. The process entails heating the steel channels until they reach their melting point and subsequently utilizing a filler material to amalgamate them. Depending on the specific necessities and the nature of the steel channels being united, welding can be executed through diverse techniques such as arc welding, MIG welding, or TIG welding. Nevertheless, it is imperative to guarantee the adherence to proper welding procedures and techniques to attain a weld of exceptional quality that meets the desired standards of strength and integrity.

- Q: What are the factors that affect the strength of steel channels?

- The factors that affect the strength of steel channels include the alloy composition, heat treatment, dimensions (such as width, height, and thickness), shape, and the presence of any defects or imperfections in the material. Additionally, the manufacturing process, including the quality of the steel and any surface treatments or coatings, can also impact the strength of steel channels.

- Q: Are steel channels suitable for solar panel installations?

- Yes, steel channels are suitable for solar panel installations. Steel channels, also known as steel C-channels or U-channels, are commonly used as mounting structures for solar panels. They provide a strong and durable support system for the panels, ensuring their stability and longevity. Steel channels are preferred for solar panel installations due to their high strength-to-weight ratio, making them capable of withstanding various environmental conditions. They offer excellent resistance to corrosion, which is crucial for outdoor installations exposed to rain, snow, and humidity. Additionally, steel channels can be customized and fabricated to fit specific solar panel dimensions, allowing for easy and secure attachment. Moreover, steel channels are cost-effective compared to other mounting options, such as aluminum or stainless steel. They are readily available in the market and can be easily installed by professionals. The versatility of steel channels also makes them suitable for both ground-mounted and rooftop solar panel installations. In conclusion, steel channels are a reliable and suitable choice for solar panel installations. Their strength, durability, resistance to corrosion, cost-effectiveness, and ease of installation make them an ideal choice for supporting solar panels and ensuring their optimal performance.

- Q: How do steel channels contribute to the overall sustainability of a solar power plant?

- Steel channels contribute to the overall sustainability of a solar power plant in several ways. Firstly, steel channels are used in the construction of the solar panel mounting system. These mounting systems are essential for securing the solar panels in place and ensuring optimal sun exposure. By using steel channels, which are durable and long-lasting, the mounting system can withstand various weather conditions and remain intact for a longer period of time. This reduces the need for frequent maintenance and replacement, thereby reducing the environmental impact associated with the production and disposal of materials. Moreover, steel channels provide structural support to the solar panels, ensuring their stability and longevity. This is particularly important in regions prone to high winds, storms, and seismic activities. By using steel channels, the solar power plant can withstand these natural events and continue to generate clean energy without interruption. This resilience reduces the risk of damage or downtime, resulting in a more reliable and sustainable energy source. Additionally, steel channels can be made from recycled steel, which further enhances the sustainability of a solar power plant. Using recycled steel reduces the demand for virgin steel production, which is an energy-intensive process with significant carbon emissions. By opting for recycled steel channels, the solar power plant can minimize its carbon footprint and conserve natural resources. Furthermore, steel channels can be designed in a way that facilitates easy installation and maintenance of the solar panels. This not only reduces the labor and time required for installation but also allows for efficient cleaning and upkeep of the panels. Regular cleaning of solar panels is essential to maximize their energy generation capacity. By utilizing steel channels that enable easy access to the panels, the plant can ensure optimal cleanliness and efficiency, ultimately contributing to the overall sustainability of the solar power plant. In conclusion, steel channels play a crucial role in enhancing the overall sustainability of a solar power plant. They provide durability and stability to the solar panel mounting system, reducing the need for frequent maintenance and replacement. Their use of recycled steel helps minimize the environmental impact associated with steel production. Additionally, steel channels facilitate easy installation, maintenance, and cleaning of the solar panels, ensuring their optimal performance and efficiency. With these contributions, steel channels significantly contribute to the long-term sustainability and viability of a solar power plant.

- Q: How do steel channels contribute to the overall cost-effectiveness of a project?

- Steel channels contribute to the overall cost-effectiveness of a project in several ways. Firstly, they are lightweight yet strong, allowing for efficient transportation and installation, reducing labor and transportation costs. Secondly, their durability and resistance to corrosion minimize maintenance and replacement expenses over time. Additionally, steel channels are readily available and can be easily fabricated to specific project requirements, eliminating the need for custom-made components and reducing material costs. Overall, the use of steel channels helps optimize project budgets while ensuring long-term structural integrity.

- Q: British standard I-beam 203*203*46 size

- I-beam is mainly divided into ordinary I-beam, light I-beam and H steel three.Ordinary I-beam, light I-beam flange is variable cross-section, depending on the thickness of the web, the external thin; H steel: HW, HM, HN, HEA, HEB, HEM and so on, the flange of I-beam is a uniform sectionOrdinary I-beam, lightweight I-beam has formed the national standard, the common 10# I-beam is equivalent to the Internet I100 (such as 10# also channel equivalent channel (U100) for the implementation of the standards of different countries, which have subtle differences in their specifications)

- Q: Are steel channels resistant to corrosion?

- Steel channels, in general, display resistance to corrosion. Typically fashioned from stainless steel, these channels possess a significant chromium content that generates a safeguarding layer on the exterior, thus hindering corrosion. Recognized for their remarkable ability to withstand rust, staining, and corrosion, stainless steel channels become an ideal choice for implementation in several industries, encompassing construction, manufacturing, and infrastructure. Nonetheless, it is crucial to bear in mind that the extent of corrosion resistance may fluctuate in accordance with the precise grade and composition of the steel employed. Consistent maintenance and appropriate handling are necessary measures to ensure the durability and corrosion resistance of steel channels.

- Q: Can steel channels be used in modular construction?

- Yes, steel channels can be used in modular construction. Steel channels are commonly used as structural components in modular construction due to their strength, durability, and versatility. They provide excellent support and stability to modular buildings, ensuring that they can withstand various loads and environmental conditions. Additionally, steel channels can be easily fabricated and assembled, making them suitable for the fast and efficient construction process required in modular construction. Overall, steel channels are a reliable and efficient choice for modular construction projects.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Southeast Asia; Africa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 15%-20% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | average |

Send your message to us

Cold Rolled C Channel

- Loading Port:

- Tianjin Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Tons m.t.

- Supply Capability:

- 1000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords