U Channel steel

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of U Channel Steel:

1.Our company enjoys high reputation on manufacturing and supplying U channel steel. Among those steel products, the U channel steel as per japanese, chinese and european can be regarded as our primary products.

Under those standard, the material grade includes: GB Q235B,GB Q345B/JIS G3192, SS400/EN 10025,S235JR and so on.

Here,the U channel steel as per japanese standard is posted just as reference.

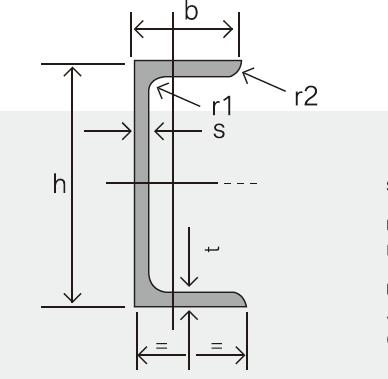

2. Dimension Figure:

Note:1.The height ranges from 50mm to 300mm

2.The breadth ranges from 25mm to 89mm

3.Theoretically speaking, the flange of U channel steel should bear stress, it’s to say that the U channel should be upright rather than lying under construction. Therefore, we strictly control the tolerance of the flange thickness.

3.The sections of U Channel Steel as per JIS Standard are shown in the below table:

JIS U CHANNEL | Standard h | Sectional b | Dimension s | t | Mass: Kg/m |

| (mm) | (mm) | (mm) | (mm) |

|

50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

|

|

|

|

|

|

100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

|

|

|

|

|

|

125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

|

|

|

|

|

|

150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

150x75 | 150 | 75 | 6.5 | 10.00 | 24.00 |

|

|

|

|

|

|

200X80 | 200 | 80 | 7.5 | 11.00 | 24.60 |

5.Mechanical Property of U Channel Steel as per JIS Standard:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

6. Chemical Composition of U Channel Steel as per JIS Standard:

Grade | Element(%) | |||

C | Mn | P | S | |

SS330 | -- | -- | ≦0.050 | ≦0.050 |

SS400 | ||||

SS490 | ||||

SS540 | ≦0.30 | ≦1.60 | ≦0.040 | ≦0.040 |

Note: we are also competent to supply structure steel u channel as per other sections, which depends on the customer's requirements for the quantity.

Applications of U Channel Steel:

U channel steel could be regarded as carbon steel or plain steel. Typically, it is stiff and strong. Carbon steels do rust easily, but they can be easily painted or primed. They are cheap so they are the normal choice for most fabrications. U channel steel is often used as supporting members, most commonly in the house raising industry to strengthen timber bears under houses. Transmission line towers.

And our products are widely used in Architectural Constructions,Telecom tower,Sub Station Structure,Microwave tower Factory and warehousing shed,Electrification projects, poles and earthing E.O.T. cranes,Material handling equipments,Ship building,Automobile

Package & Delivery of U Channel Steel:

The u channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

And u channel steel could be loaded into 20ft or 40ft container, or by bulk cargo. If the weight of each bundle reaches less than 3.5 mt, the loading by break bulk cargo should be choosed. When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

In a word, we do try our best to satisfy all the customer's requirements.

Production Flow of Steel U Channel:

1.The steel billet shall be heated in the high temperature furnace.

2. The heated steel billet shall be rolled five to nine times with the aim of shaping the general figure of steel u channel.

3. The rolled steel u channel should be put onto the cooling bed to make the temperature low.

4. The steel u channel should be straighted on the straightener.

5. The straighted steel u channel will be cut into meters by saw, as per customer's requirements.

- Q: How do steel channels perform under wind loads?

- Construction and engineering projects often utilize steel channels to provide stability and structural support. Steel channels excel in resisting wind loads due to their strength and rigidity. Wind loads exert forces on structures, including uplift and lateral forces. Steel channels possess high tensile strength, enabling them to withstand these forces without significant deformation or failure. These channels are designed to effectively distribute and transfer wind forces to the foundation or other structural elements. The performance of steel channels under wind loads is also influenced by their shape and cross-sectional design. The profile of a steel channel efficiently dissipates wind energy, reducing the risk of structural damage or failure. The open design of these channels minimizes wind resistance, further enhancing their ability to withstand wind loads. Furthermore, steel channels can be customized and engineered to meet specific wind load requirements based on geographic location. Engineers consider factors such as wind speed, direction, and exposure to determine the optimal size, shape, and spacing of steel channels. In conclusion, steel channels are highly dependable and effective in withstanding wind loads. Their high tensile strength, shape, and customization options make them an excellent choice for structures exposed to strong winds. Whether it be a bridge, building, or any other construction project, steel channels offer the necessary support and stability to withstand wind loads and maintain the structural integrity of the entire system.

- Q: What is the standard length of steel channels?

- The specific industry and application determine the possible variations in the standard length of steel channels. Typically, steel channels are found in standard lengths of 20 feet or 6 meters. These lengths are frequently chosen for their convenience in transportation, handling, and alignment with prevalent building and construction methods. It is worth mentioning that custom lengths can be acquired to meet project-specific needs. Nevertheless, the widely utilized and easily accessible standard length in the market remains 20 feet or 6 meters.

- Q: How do steel channels resist corrosion?

- The main reason why steel channels are resistant to corrosion is because of the protective oxide layer that forms on their surface. This layer, also known as a patina, acts as a barrier between the metal and its surroundings, preventing direct contact and reducing the likelihood of corrosion. The formation of the patina occurs through a process called passivation, which happens when steel is exposed to oxygen in the air or water. Passivation assists in creating a stable and firmly attached layer of oxide that effectively inhibits the corrosion process. Additionally, steel channels can receive further protection against corrosion through different surface treatments like galvanization or coating with materials that are resistant to corrosion, such as zinc or paint. These treatments provide an additional layer of defense against moisture, chemicals, and other elements that cause corrosion. It is crucial to regularly maintain and inspect steel channels to prevent corrosion, as any damages or breaches in the oxide layer can expose the underlying metal and increase the risk of corrosion. In summary, the combination of the natural passivation process, surface treatments, and proper maintenance contribute to the high resistance of steel channels to corrosion, ensuring their durability and longevity in various applications.

- Q: What are the different testing methods for steel channels?

- There are several testing methods available for steel channels to ensure their quality and performance. These methods include dimensional inspection, visual inspection, magnetic particle testing, ultrasonic testing, and load testing. 1. Dimensional Inspection: This method involves measuring the dimensions of the steel channels to ensure they meet the required specifications. It checks for deviations in length, width, height, and thickness. 2. Visual Inspection: Visual inspection is conducted to detect any visible defects such as surface cracks, corrosion, dents, or other imperfections that can affect the structural integrity or aesthetics of the steel channels. 3. Magnetic Particle Testing: This non-destructive testing method uses magnetic fields and magnetic particles to identify surface and near-surface defects in the steel channels. It is particularly effective in detecting cracks, weld defects, and other discontinuities. 4. Ultrasonic Testing: Ultrasonic testing utilizes high-frequency sound waves to detect internal flaws or defects in the steel channels. It can identify cracks, voids, and other irregularities that may not be visible to the naked eye. 5. Load Testing: Load testing involves subjecting the steel channels to a specified load or force to evaluate their strength and structural integrity. This method helps determine if the channels can withstand the expected loads and stresses they will encounter in their intended applications. These testing methods provide crucial information about the quality and suitability of steel channels for various construction and engineering purposes. By conducting these tests, manufacturers and users can ensure the safety, reliability, and performance of steel channels in their respective applications.

- Q: How do steel channels perform in extreme temperature conditions?

- Steel channels excel in extreme temperature conditions because of their remarkable thermal conductivity and low thermal expansion coefficient. As a result, steel channels effectively transfer heat and cold, ensuring their structural integrity and stability in even the most extreme temperature settings. Moreover, steel channels boast a high melting point, rendering them impervious to deformation or structural failure, even when subjected to elevated temperatures. The exceptional strength and durability of steel further enhance its ability to withstand thermal stress, minimizing the risk of warping, bending, or cracking. Hence, steel channels offer an unwavering option for applications necessitating stability, strength, and resistance to extreme temperatures.

- Q: How do steel channels contribute to the stability of a structure during hurricanes?

- The stability of a structure during hurricanes is greatly improved by the presence of steel channels. These channels possess exceptional strength and can bear heavy loads, which is why they are widely used in the construction industry to provide support and reinforcement. During hurricanes, when strong winds and intense forces assail a building, the steel channels effectively distribute these forces evenly throughout the structure. This prevents the formation of stress points and reduces the probability of structural failure. Additionally, steel channels are often incorporated into the framework of walls, roofs, and floors in a building. By doing so, they create a rigid structure that enhances overall stability. This rigidity enables the building to withstand the lateral forces and uplift pressures generated by hurricane winds. By resisting these forces, the steel channels minimize the risk of the structure collapsing or sustaining severe damage during a hurricane. Moreover, steel channels can be strategically placed in critical areas within a building to reinforce specific regions that are susceptible to wind and storm damage. A prime example of this is the reinforcement of window and door openings, which are particularly vulnerable to wind pressure. By installing steel channels around these openings, the structure becomes more resistant to the uplift and inward forces caused by high-speed winds. This reduces the likelihood of these openings being blown out or compromised. Furthermore, steel channels possess remarkable durability and resistance to corrosion, which makes them ideal for withstanding the adverse environmental conditions associated with hurricanes. Unlike other construction materials, steel channels do not deteriorate or weaken when exposed to moisture, saltwater, or high humidity levels. This longevity ensures that the structural integrity of the building remains intact, even after multiple hurricane events. In conclusion, the presence of steel channels is of utmost importance in enhancing the stability of a structure during hurricanes. Their exceptional strength, load-bearing capacity, rigidity, and resistance to environmental conditions make them an essential component in the construction of hurricane-resistant buildings. By effectively distributing forces, reinforcing critical areas, and maintaining their structural integrity, steel channels play a pivotal role in safeguarding structures and their occupants from the destructive forces of hurricanes.

- Q: What are the different types of bracing systems used with steel channels?

- Steel channels can be combined with various bracing systems to meet the specific needs and requirements of a project. The following are a few examples: 1. Cross bracing: The most commonly used bracing system for steel channels involves diagonal members or cables arranged in a crisscross pattern between two or more steel channels. This type of bracing ensures an even distribution of the load and enhances the stability of the structure. 2. K-bracing: Rectangular or square buildings often employ K-bracing, which involves diagonal members or cables forming a K-shape between steel channels. It offers strong resistance against lateral forces. 3. Chevron bracing: Similar to K-bracing, chevron bracing also utilizes diagonal members or cables. However, in this system, the diagonal members form a V-shape or chevron pattern. Chevron bracing is ideal for structures with limited space, as it requires less material and allows for more open floor plans. 4. X-bracing: This bracing system uses diagonal members or cables arranged in an X-shape between steel channels. It is popularly used in buildings with long spans or high wind loads due to its excellent resistance against lateral forces. 5. Portal bracing: Buildings with large openings, such as garages or warehouses, often incorporate portal bracing. This involves adding diagonal members or cables to create a portal frame between steel channels. The purpose of this type of bracing is to distribute the load evenly and prevent deformation of the structure. 6. Eccentric bracing: Eccentric bracing is a specialized system that allows for controlled yielding during seismic events. It involves placing diagonal members or cables off-center from the vertical axis of the steel channels. This arrangement dissipates energy and minimizes the impact of seismic forces. These are just a few examples of the bracing systems compatible with steel channels. The choice of bracing system depends on factors such as structural requirements, building codes, and project-specific needs.

- Q: Are steel channels suitable for the power generation manufacturing industry?

- Yes, steel channels are suitable for the power generation manufacturing industry. Steel channels offer excellent strength and durability, making them ideal for supporting heavy equipment and structures in power plants. They can be customized to meet specific requirements and are resistant to corrosion, which is crucial in power generation facilities where exposure to moisture and chemicals is common. Additionally, steel channels have excellent thermal conductivity, ensuring efficient heat transfer in power generation processes.

- Q: What are the different methods of protecting steel channels from weathering?

- To prevent weathering and extend the lifespan of steel channels, there are multiple methods to choose from. These methods aim to combat corrosion and safeguard the integrity of the channels. The following are some commonly used techniques: 1. Coatings: Applying protective coatings is highly effective in preventing weathering on steel channels. These coatings can come in the form of paint, epoxy, or zinc-based materials. By acting as a barrier, the coating stops moisture and oxygen from reaching the steel surface and causing corrosion. 2. Galvanization: Galvanizing steel channels involves coating them with a layer of zinc. This method provides exceptional protection against weathering as the zinc acts as a sacrificial anode, corroding instead of the steel. Galvanized steel channels exhibit enhanced corrosion resistance and can withstand harsh weather conditions. 3. Powder coating: Powder coating is a popular technique for shielding steel channels from weathering. It entails applying a dry powder to the channels' surface, which is then heated and cured to form a durable protective layer. Powder coating not only provides a decorative finish but also offers excellent resistance to corrosion, UV rays, and weathering. 4. Stainless steel: Utilizing stainless steel channels is another effective means of weathering protection. Stainless steel contains chromium, which forms a passive oxide layer on the surface, safeguarding it from corrosion. Stainless steel channels exhibit high resistance to rust, making them suitable for outdoor applications. 5. Design considerations: Proper design and engineering can also play a crucial role in protecting steel channels from weathering. This involves incorporating drainage systems to prevent water accumulation, ensuring adequate ventilation to minimize moisture buildup, and avoiding the use of dissimilar metals that could trigger galvanic corrosion. In conclusion, several methods are available for protecting steel channels from weathering. Each method offers varying levels of protection, and the choice depends on factors such as the environment, budget, and desired lifespan of the steel channels. Selecting the appropriate method is crucial to ensure the durability and performance of steel channels in outdoor applications.

- Q: How are steel channels installed on-site?

- Steel channels are installed on-site through a systematic process to ensure their proper placement and stability. The installation process typically involves the following steps: 1. Planning and preparation: Before installation, detailed planning is done to determine the exact location, size, and layout of the steel channels. This includes obtaining necessary permits, surveying the site, and coordinating with other construction activities. 2. Site preparation: The installation area needs to be cleared of any debris or obstructions. Excavation may be required to create a stable foundation for the channels, depending on the site conditions. 3. Aligning and leveling: The first step in installation is to align and level the steel channels. This is crucial for ensuring their structural integrity and proper functioning. Laser levels or other precise measurement tools are used to achieve the desired alignment. 4. Marking and positioning: The exact positions of the steel channels are marked on the ground or walls, indicating where they will be installed. This helps in guiding the installation process and ensuring accurate placement. 5. Fixing anchor bolts: Anchor bolts are used to secure the steel channels to the foundation or supporting structure. These bolts are drilled into the concrete or steel frames and properly aligned with the marked positions. 6. Lifting and placing: Once the anchor bolts are fixed, the steel channels are lifted into position using cranes or other lifting equipment. Great care is taken during this process to avoid any damage to the channels or surrounding structures. 7. Fastening and welding: The steel channels are then firmly fastened to the anchor bolts using nuts and washers. Depending on the design and requirements, welding may also be done to provide additional strength and stability. 8. Checking alignment and level: After installation, the alignment and level of the steel channels are rechecked to ensure they meet the required specifications. Adjustments, if necessary, are made at this stage to achieve the desired alignment. 9. Final inspection: Once the steel channels are installed, a thorough inspection is conducted to ensure their proper installation and adherence to safety standards. Any defects or issues are identified and rectified before proceeding with further construction activities. Overall, the installation of steel channels on-site requires careful planning, accurate measurement, and precise execution to ensure their proper alignment and structural integrity. By following established guidelines and safety protocols, steel channels can be installed effectively to provide the desired support and functionality in various construction projects.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1993 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South Asia Middle East; Southeast Aisa; south Korea |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | average |

Send your message to us

U Channel steel

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords