Steel Column To Steel Beam Connection

Steel Column To Steel Beam Connection Related Searches

Steel Structure Beam Column Connection Joining Steel Beams Steel Column Connection To Foundation Bolting Steel Beams Together Structural Columns And Beams Stainless Steel Coupling Stainless Steel Beam Clamps Galvanized Steel Beams Stainless Steel I Beam Stainless Steel Quick Connect L Beam Steel Stainless Steel Belt Sublimating On Stainless Steel Glue To Stainless Steel Stainless Steel Tie Wire Sublimation On Stainless Steel Beam Joints Stainless Steel Ties Stainless Steel Rope Chain Solder To Stainless Steel Simple Beam Bridge Stainless Steel Screening Stainless Steel Collision Stainless Steel Pipe Fitting Pitting On Stainless Steel Stainless Steel Bead Chain Stainless Steel Sheeting Annealing Stainless Steel Stainless Steel Beads Steel Partition WallSteel Column To Steel Beam Connection Supplier & Manufacturer from China

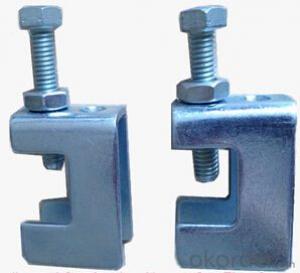

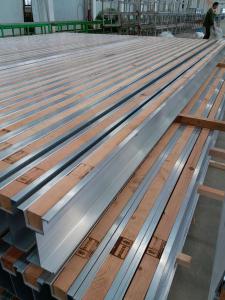

Steel Column To Steel Beam Connection is a type of construction component that plays a crucial role in the structural integrity of buildings and infrastructures. This connection is designed to join steel columns and steel beams, ensuring stability and strength in various construction projects. It is essential for architects and engineers to select the appropriate connection type based on the specific requirements of the project, such as load-bearing capacity, seismic resistance, and aesthetic considerations.The application and usage scenarios of Steel Column To Steel Beam Connection are vast, as it is a fundamental element in the construction of commercial buildings, industrial facilities, and even residential structures. This connection is particularly useful in areas prone to earthquakes or other natural disasters, where a robust and flexible structure is necessary to withstand external forces. Additionally, it is employed in the construction of bridges, high-rise buildings, and other large-scale projects that demand high levels of structural support.

Okorder.com is a reputable wholesale supplier of Steel Column To Steel Beam Connection, boasting a large inventory of this essential construction component. With a commitment to quality and customer satisfaction, Okorder.com offers a wide range of Steel Column To Steel Beam Connection products to cater to the diverse needs of the construction industry. By partnering with Okorder.com, contractors and engineers can access reliable and high-quality connections, ensuring the safety and longevity of their projects.

Hot Products