Shear Stud Connectors for Steel Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:M19*115

Material:Carbon Steel

Surface Finishing:Plain&Black

Grade:A

Certification:ISO, CE, SGS

Customized:Customized

Product Name:Nelson Shear Stud Connector

Type:Nelson Shear Stud

Raw Material:Carbon Steel Ml15al (Swrch15A)

Support Standard:ISO 13918 ; GB/T10433; Aws D1.1

Surface Treatment:Plain &Black

Diameter:M10 M13 M16 M19 M22 M25

Length:40-300mm

Tensile Strength:>= 450n/Mm2

Yield Point:>= 350n/Mm2

Elongation Percentage:>= 15%

Export Markets:Global

Additional Info.

Packing:Carton &Barrel &Pallet for Welding Shear Stud

Standard:ISO 13918; GB/T10433; AWS D1.1

Origin:Tianjin

HS Code:7318290000

Production Capacity:2000 Ton/Tons Per Month 100X20′′gp Shear Stud

Product Description

Shear studs are used in stud welding to secure steel framed buildings to create a shear connection between the steel and the concrete. We supply and fix all available sizes of welded shear studs for through deck and straight to steel welding.

All our products meet the current standards and specifications

The ISO 13918 SINOARSTM shear studs (shear connectors) use the ISO13918 standard Type UF and PF ceramic

ferrules,other special type available upon request.

When inquire prices and ordering, please specify name, standard, type, specification (LBW), quantity, special requirements(if have), etc., eg.

Shear Stud, ISO 13918, Type SD, 22x150 (LBW), 60,000 Pieces.

ISO 13918 Nelson Welding Shear Stud Connector

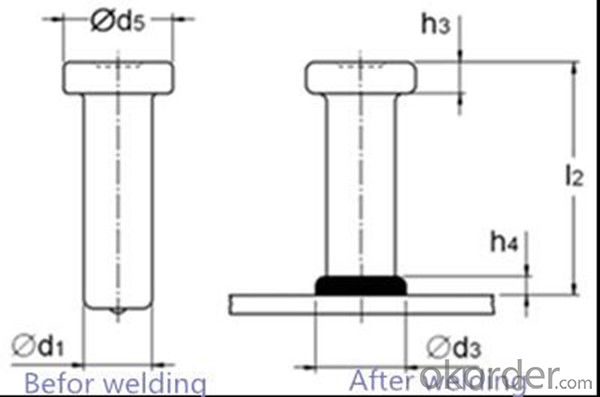

Production Discription:

| ||||||

d1-0.4 | 10 | 13 | 16 | 19 | 22 | 25 |

d5±0.3 | 19 | 25 | 32 | 32 | 35 | 41 |

d3±0.3 | 13 | 17 | 21 | 23 | 29 | 31 |

h3±0.5 | 7 | 8 | 8 | 10 | 10 | 12 |

h4 | 2.5 | 3 | 4.5 | 6 | 6 | 7 |

L1±1.5 | 40-105 | 40-160 | 40-200 | 40-250 | 60-250 | 60-250 |

Burn off | 3 | 3 | 4 | 5 | 5 | 6 |

Ferrule | UF10 | UF13 | UF16 | UF19 | UF22 | UF25 |

1.Burn off value shown are for welding to bare steel

2.There are two kinds of ceramic ferrule, one is through deck type which has 8 teeth,

the other one is common type which has 18 teeth.

The price is same for these two types.

3.The UFB type ceramic ferrule are for through deck welding , with 8 teeth !

| ||||

1/2-0.01 | 5/8-0.01 | 3/4-0.015 | 7/8-0.015 | |

d5±1/64 | 1 | 1-1/4 | 1-1/4 | 1-3/8 |

h3 | 9/32 | 9/32 | 3/8 | 3.8 |

L1±1/16 | 2-5.9 | 2-7.874 | 2-9.84 | 3.15-9.84 |

Burn off | 0.125 | 0.187 | 0.187 | 0.187 |

Ferrule | UF13 | UF16 | UF19 | UF22 |

| ||||||

Material | C | Si | Mn | P | S | Al |

ML15AL | 0.13-0.18 | ≤0.10 | 0.30-0.60 | ≤0.035 | ≤0.035 | ≥0.020 |

SWRCH18A | 0.15-0.20 | ≤0.10 | 0.60-0.90 | ≤0.030 | ≤0.035 | ≥0.020 |

| Mechanical Properties | ||||

| Country | Tensile strength BN/mm2 | Yield point BS/mm2 | Elongation percentage δ% | Contraction percentage Ψ% |

| BS EN ISO13918:2008 | ≥450 | ≥350 | ≥15 | |

| USA ANSI/AWS D1.1 | ≥415 | ≥345 | δ4≥20 | ≥50 |

| CHINA GB/T10433 | ≥400 | ≥320 | δ5≥14 | |

By advanced production technology and strictly inspection system, our shear stud

connectors meet the standard of EN ISO 13918 or AWS D1.1,

both dimensions and mechanical properties are according to the above standards:

Tensile strength min. 450Mpa, Yield strength min. 350Mpa, Elongation min 15%, etc.

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What is the fastener and others?

- Fasteners are collectively referred to as a class of mechanical parts used to fasten two or more parts (or components) into a unit. Fasteners include bolts, studs, screws, nuts, washers, Pin, etc.,

- Q: what parts do Fasteners include

- A type of fastener that has no head and only the ends that are threaded at both ends. When connected, it must be screwed into the part with internal screw hole, the other end through the through hole with the parts, and then screw the nut, even if the two parts fastened into a whole. This type of connection is called a stud connection and is a detachable connection. Mainly used for connecting parts of a larger thickness, requiring a compact structure, or because of frequent demolition, should not be used bolted connection occasions.

- Q: High-strength screw standard parts of the quality of what data

- Material: Does the chemical composition meet the standard requirements Appearance: Good surface treatment: Does it meet the standard requirements? If 1 and 4 problems, this batch of bolts directly failed,

- Q: Fasteners often say that the nature of galvanized oxidation is what it means

- True color means that the surface of the fastener is not treated. Galvanized refers to non-zinc easily oxidized metal fastener surface coated with a layer of zinc, the role is to prevent its rust. Oxidation refers to the surface of the metal fastener through a chemical reaction to produce a layer of rust-proof film, the main role is rust, the other can also beautify the appearance.

- Q: The main meaning is that the design to make some specific requirements to achieve consistency.

- Referred to the selection must be selected in the national standard parts, otherwise the changeability does not exist. Speaking of norms nothing less than the following: function according to national standards (strength, rust, shape ....);

- Q: Is it hard to heat the fasteners?

- Heat treatment mainly refers to the dipped fire. Dip the fire is not dipped into the water, is the oil. So the quality of oil, dipped in the temperature of the fire, dipped in the fire time are demanding Moreover, some special requirements need to double the fire, the difficulty is indeed great. In addition, heat treatment often take into account the requirements of the next step surface treatment, so have to consider

- Q: What is the name of the screw (fastener)?

- By specifications: M3. M4. M5. M6. M8. M10. M12 By head type: a. Flat head b. Small head (countersunk head)By the shape: a. Cylindrical light body b. Hexagonal c. Semi-hexagonal d. Cylindrical column posture

- Q: Are there categories of fasteners classified by material?

- Low carbon steel Q235, low carbon alloy steel Q345, 10B21 medium carbon steel 35K 45K, high carbon alloy steel 40CR 435crmo, stainless steel 303 304 316. Stainless steel 201. etc., the number of materials, but generally determine the amount of carbon fasteners, etc. To what level. Of course, like 10B21 this low-carbon alloy steel can reach 8.8 level

- Q: Fasteners are used in what areas?

- General use of a wide range of applications, such as machinery, electronics, transportation, furniture, construction, chemicals, ships, toys, etc., life is everywhere. Aerospace fasteners are fasteners designed for aerospace vehicles.

- Q: Our company to purchase a number of fasteners to see when the CAD drawings in the technical requirements I do not know the specific to write those content

- Name: Bolt nut flat cushion pad - (should be written in the national label) Drawing No .: Ask the engineer Material: Q235 Q235 steel spring steel ---- ordinary 35 steel 35 steel spring steel ---- high strength ratio: according to the actual Drawing quality: check the information or do not fill the level: 4.8 5 200HV 65MN ------ ordinary 8.8 8 300HV 65MN ------ high strength specifications: write their own

Send your message to us

Shear Stud Connectors for Steel Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords