Steel prop & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

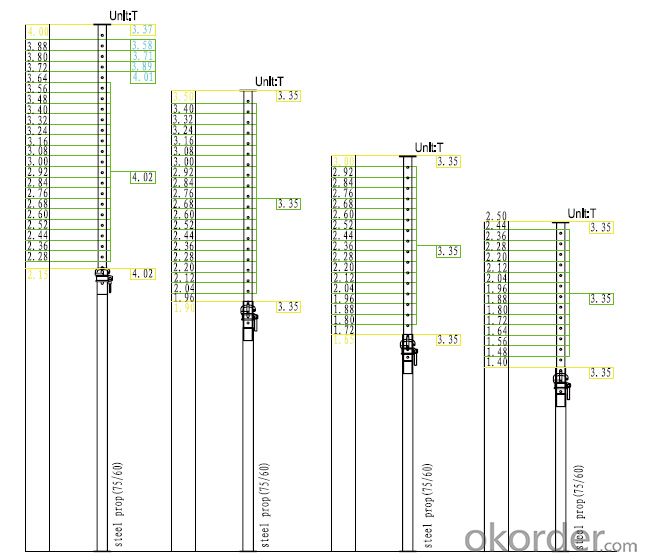

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Are steel props commonly used in stadium construction projects?

- Yes, steel props are commonly used in stadium construction projects. Steel props provide strong support and stability during the construction process, allowing for the safe and efficient erection of large structures such as stadiums.

- Q: Are steel props suitable for supporting floor slabs?

- Yes, steel props are suitable for supporting floor slabs. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to provide temporary support to horizontal structures like floor slabs. They are adjustable in height, making them versatile and adaptable to different slab thicknesses and load requirements. Steel props consist of a steel tube with an inner screw mechanism that allows for easy and precise height adjustment. They are designed to withstand heavy loads and provide stability and support during construction activities. The outer tube is made of strong steel, while the inner screw mechanism is typically made of hardened steel, ensuring durability and reliability. One of the key advantages of using steel props for supporting floor slabs is their load-bearing capacity. Steel props are capable of supporting significant loads, making them suitable for a wide range of construction projects. Additionally, their adjustable height feature allows for flexibility in supporting slabs of varying thicknesses. Steel props are also easy to install and dismantle, saving time and effort during construction. They can be quickly adjusted to the desired height and secured in place. Moreover, they are reusable, making them a cost-effective solution for supporting floor slabs in multiple projects. In summary, steel props are suitable for supporting floor slabs due to their load-bearing capacity, adjustable height feature, durability, and ease of installation. They are a reliable and versatile solution for temporary support during construction activities.

- Q: Can steel props be used for temporary support in railway construction?

- Yes, steel props can be used for temporary support in railway construction. Steel props are commonly used in construction projects to provide temporary support to structures until they are able to support themselves. In railway construction, steel props can be used during the installation of new tracks, bridges, or tunnels. They can be used to support the weight of heavy machinery or equipment during the construction process. Steel props are strong, durable, and easily adjustable, making them an ideal choice for temporary support in railway construction.

- Q: How do you prevent damage to adjacent structures when using steel props?

- When using steel props, there are several measures that can be taken to prevent damage to adjacent structures. 1. Conduct a thorough survey and assessment: Before using steel props, it is essential to conduct a detailed survey of the surrounding area. This should include identifying any adjacent structures, utilities, or sensitive areas that may be at risk of damage. Assess the condition of these structures and determine their load-bearing capacity. 2. Ensure proper installation and positioning: Steel props should be installed and positioned correctly to provide adequate support. This involves following the manufacturer's instructions and guidelines, ensuring that the props are securely fastened and properly aligned. It is crucial to check for any obstructions or uneven surfaces that may affect the stability of the props. 3. Use appropriate load-bearing capacity: Make sure to select steel props with the appropriate load-bearing capacity for the specific application. Overloading the props can lead to structural failure and potential damage to adjacent structures. Consult with structural engineers or experts if necessary to determine the correct load-bearing capacity required. 4. Monitor and inspect regularly: Regular monitoring and inspection of the steel props during the construction process are essential. This includes checking for any signs of movement, deformation, or stress on the props or adjacent structures. Any abnormalities should be addressed immediately to prevent further damage. 5. Implement protective measures: Depending on the situation, additional protective measures may be necessary to prevent damage to adjacent structures. This can include using structural shoring, bracing, or strengthening techniques to distribute the loads more evenly and minimize any potential impact on surrounding structures. 6. Communication and coordination: Open communication and coordination with the project team, including adjacent property owners, is crucial. Informing them about the construction activities, potential risks, and mitigation measures will help minimize any potential damage and ensure everyone is prepared and aware of the situation. Ultimately, preventing damage to adjacent structures when using steel props requires careful planning, proper installation, regular monitoring, and the implementation of protective measures. Following these steps will help maintain the safety and integrity of both the construction site and the surrounding structures.

- Q: Can steel props be used in supporting temporary stages and platforms?

- Yes, steel props can be used in supporting temporary stages and platforms. Steel props, also known as adjustable steel columns or acrow props, are versatile and robust support systems commonly used in construction and temporary structures. They are designed to provide temporary support to horizontal and vertical loads. Steel props are adjustable in height, allowing them to be easily customized to the required height for supporting stages and platforms. Additionally, their strong steel construction ensures stability and safety, making them suitable for supporting heavy loads and providing a secure foundation for temporary structures.

- Q: What are the common load testing methods for steel props?

- Steel props undergo various load testing methods to assess their strength and structural integrity. These methods, widely utilized, include: 1. Static Load Testing: By employing hydraulic jacks or weights, a predetermined static load is gradually applied to the steel prop. The prop's deflection and deformation are closely monitored until the desired testing load is reached. This test aids in determining the prop's maximum load capacity and deformation characteristics under static conditions. 2. Proof Load Testing: A load higher than the expected working load is applied to the steel prop in this method. The prop endures this load for a specified duration to ensure it can withstand the intended working load without permanent deformation or failure. After the test, a thorough inspection is conducted to assess the prop's condition and suitability for use. 3. Ultimate Load Testing: This testing method involves subjecting the steel prop to an excessive load until it reaches its breaking point. The objective is to ascertain the maximum load the prop can withstand before failure, providing valuable information about its ultimate strength and safety factor. 4. Dynamic Load Testing: Real-life dynamic loads, like vibration or impact, are simulated on the steel prop in this method. The prop experiences repetitive loading cycles, and its response to these dynamic loads is measured. This test aids in evaluating the prop's fatigue resistance and durability under dynamic conditions. 5. Non-Destructive Testing (NDT): To inspect steel props without causing damage, NDT techniques like ultrasonic testing, magnetic particle testing, or radiography are frequently used. These methods can detect flaws, cracks, or imperfections in the material that may compromise the prop's load-bearing capacity. It is crucial to bear in mind that load testing methods may differ depending on the specific requirements and standards of the industry or project. Consulting relevant codes, standards, or structural engineers is essential to determine the appropriate load testing method for steel props in a particular context.

- Q: Can steel props be used for supporting temporary aerial platforms or lifts?

- Supporting temporary aerial platforms or lifts can be achieved using steel props. These props, also referred to as adjustable steel props or scaffolding props, are commonly utilized in construction projects to offer temporary support for structures or platforms. Their adjustable height feature makes them suitable for various applications, including supporting aerial platforms or lifts. Steel props are renowned for their strength and stability, making them a dependable choice for establishing a secure and sturdy foundation for temporary platforms or lifts. Moreover, their height can be easily modified, providing flexibility in determining the desired elevation for the platforms or lifts. However, it is imperative to ensure the proper installation of steel props and adherence to required safety standards to guarantee the safety of workers and the stability of the supported structure.

- Q: Can steel props be used in the construction of wastewater treatment plants?

- Yes, steel props can be used in the construction of wastewater treatment plants. Steel props are commonly used in construction projects to support structures and provide temporary support during the construction process. In the case of wastewater treatment plants, steel props can be used to support various components such as tanks, pipelines, and equipment during installation. They provide stability and structural support, ensuring that the components are held securely in place. Additionally, steel props can also be used to support temporary structures like scaffolding, allowing workers to safely access different areas of the treatment plant during construction or maintenance activities. Overall, steel props are a versatile and reliable option for supporting various elements of wastewater treatment plant construction.

- Q: Can steel props be used for supporting formwork?

- Yes, steel props can be used for supporting formwork. Steel props are commonly used in construction for formwork support because of their strength and durability. They provide a stable and adjustable support system for formwork, ensuring that the formwork remains in place during concrete pouring and curing. Steel props can be easily adjusted to the required height and can support heavy loads, making them suitable for various formwork applications. Additionally, steel props are reusable, making them a cost-effective choice for formwork support.

- Q: How do steel props accommodate for changes in load during construction?

- Steel props, commonly used in construction projects, are versatile and adjustable support systems that provide temporary support to structures. These props are designed to easily modify their height and load-bearing capacity, allowing them to accommodate changes in load during construction. One way steel props handle changes in load is through their telescopic design. Composed of an inner tube that can be extended or retracted and an outer tube that provides additional support, these props can be easily adjusted to support different loads or compensate for changes in the structure's weight distribution by altering the height of the inner tube. Moreover, steel props often feature adjustable load-bearing heads. Contractors can rotate or tilt these heads to ensure even distribution and proper support of the load. By manipulating the position and orientation of the load-bearing head, contractors can effectively distribute the weight, preventing overloading on specific areas and ensuring structural stability. Furthermore, steel props are typically rated for specific load capacities and engineered to withstand various loads. This allows for the selection of props based on the anticipated load requirements of the construction project. If the load changes during construction, props with higher load capacities can be easily substituted to ensure the structure remains adequately supported. In summary, steel props offer flexibility and adaptability to accommodate changes in load during construction. Through their telescopic design, adjustable load-bearing heads, and available load capacities, they provide a reliable and efficient solution for supporting structures under varying load conditions.

Send your message to us

Steel prop & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords