Steel prop & Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp:

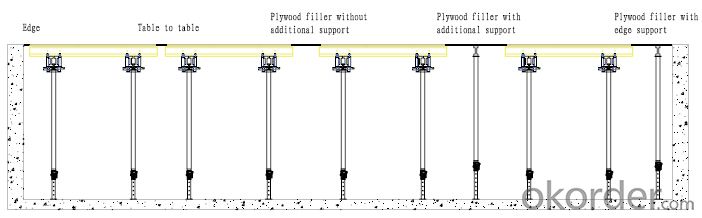

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used in marine construction?

- Yes, steel props can be used in marine construction. Steel is a durable and strong material that can withstand harsh marine environments, including saltwater, corrosion, and extreme weather conditions. Steel props are commonly used in marine construction projects such as piers, docks, bridges, and offshore platforms. These props provide structural support and stability to the construction, ensuring that it can endure the forces exerted by waves, currents, and tides. Additionally, steel props can be easily adjusted and customized to meet the specific requirements of the marine construction project. Overall, steel props are a reliable and commonly used solution in marine construction due to their strength, durability, and ability to withstand the unique challenges posed by the marine environment.

- Q: Can steel props be used to support beams and columns?

- Yes, steel props can be used to support beams and columns. Steel props are adjustable and can provide temporary support during construction or renovation projects. They are commonly used to support beams and columns when additional load-bearing capacity is required or when existing supports need to be replaced or repaired. The adjustable nature of steel props allows for precise positioning and easy installation, making them a suitable choice for supporting beams and columns in various construction scenarios.

- Q: What are the potential environmental impacts of using steel props?

- The potential environmental impacts of using steel props can be categorized into several areas. Firstly, the production of steel props requires the extraction of raw materials, such as iron ore, which can have negative impacts on the environment. Mining activities can lead to habitat destruction, soil erosion, and water pollution. Additionally, the process of refining and manufacturing steel involves significant energy consumption and the release of greenhouse gases, contributing to climate change. Secondly, the transportation of steel props from manufacturing facilities to construction sites can have environmental consequences. Long-distance transportation requires the use of fossil fuels, which leads to carbon dioxide emissions and air pollution. Moreover, heavy transportation vehicles can damage roads and cause congestion, further impacting the environment. Furthermore, the disposal of steel props after their useful life can pose environmental challenges. Steel is non-biodegradable, meaning that when props are no longer needed, they often end up in landfills. This contributes to the accumulation of waste and the usage of valuable land resources. However, it is worth noting that steel props can also have positive environmental impacts. Steel is a highly recyclable material, and the recycling of steel props can significantly reduce the need for new production and the associated environmental impacts. Steel recycling also saves energy compared to primary steel production, as it requires fewer resources and generates fewer greenhouse gas emissions. To mitigate the potential environmental impacts of using steel props, several measures can be taken. Increasing the use of recycled steel is one important step towards reducing the demand for new production and conserving resources. Implementing energy-efficient manufacturing processes and utilizing renewable energy sources can also minimize the carbon footprint of steel production. Additionally, promoting sustainable transportation practices, such as optimizing logistics and using alternative fuels, can help reduce the environmental impact of transporting steel props. Overall, while steel props have certain environmental drawbacks due to their production, transportation, and disposal, their recyclability and potential for reduced energy consumption offer opportunities for mitigating their environmental footprint.

- Q: How do you ensure proper coordination between different trades when using steel props?

- To maintain a safe and efficient construction process, it is crucial to ensure proper coordination between different trades when using steel props. The following steps can be taken to achieve this: 1. Thorough Planning: Adequate planning is essential in order to determine the number and locations of steel props required for the project. By collaborating with architects, engineers, and other trades involved, a comprehensive plan can be developed that takes into account the specific needs and requirements of each trade. 2. Effective Communication: Regular communication between the different trades is vital to ensure everyone is on the same page. It is important to conduct meetings or briefings where representatives from each trade can discuss their needs and concerns related to steel props. This helps in identifying potential clashes or conflicts and finding suitable solutions. 3. Clear Instructions: Clear and concise instructions should be provided to each trade regarding the installation, use, and removal of steel props. These instructions should include safety guidelines, load-bearing capacities, and any specific requirements to prevent accidents or damage during the construction process. 4. Site Supervision: Having a dedicated site supervisor or coordinator who oversees the activities of different trades can greatly enhance coordination. This individual can ensure that steel props are being used correctly, monitor progress, and promptly address any issues that arise. 5. Regular Inspections: Regular inspections should be conducted to verify that the steel props are being installed and used according to the specifications. These inspections can be carried out by an engineer or supervisor to ensure compliance with safety standards and address any deviations or concerns. 6. Collaboration in Design: In some cases, involving representatives from different trades during the design phase can be beneficial. By considering the requirements of various trades from the beginning, potential conflicts or coordination issues can be anticipated and mitigated in the design itself. 7. Record-Keeping: Maintaining accurate records of the installation and removal of steel props, as well as any modifications or adjustments made, can aid in coordination. This documentation can be used to track progress, identify potential issues, and provide references for future projects. By following these steps, proper coordination between different trades when using steel props can be ensured. This promotes a smoother construction process, minimizes delays, enhances safety, and improves overall project efficiency.

- Q: Are steel props suitable for supporting temporary structures?

- Yes, steel props are suitable for supporting temporary structures. They are strong, durable, and can bear heavy loads, making them an ideal choice for providing temporary support to structures during construction or renovation projects.

- Q: What are the common safety features and mechanisms found in steel props?

- Steel props, also known as adjustable steel props or steel shores, are commonly used in construction and scaffolding to provide temporary support to structures. These props are designed with several safety features and mechanisms to ensure stability and prevent accidents. One of the most common safety features found in steel props is the adjustable mechanism. This allows the length of the prop to be easily adjusted to the required height, providing a secure and stable support for the structure. The adjustable mechanism is usually equipped with a locking pin or collar, which secures the prop in place and prevents accidental movement or collapse. Another important safety feature is the load capacity rating. Steel props are designed and manufactured with specific load capacities to ensure that they can support the weight and pressure exerted by the structure. These load capacities are usually clearly marked on the props, allowing construction workers to select the appropriate props for their specific needs and ensure that they do not exceed the maximum load capacity. Steel props are also often equipped with safety pins or clips to prevent accidental disengagement of the adjustable mechanism. These pins or clips are inserted into pre-drilled holes on the prop, providing an additional layer of security and preventing the prop from accidentally collapsing or extending. Furthermore, steel props may have anti-slip features such as rubber or plastic caps on the base plate. These caps help to provide traction and prevent the prop from sliding on smooth surfaces, reducing the risk of accidents caused by instability. Additionally, some steel props may be designed with built-in leveling mechanisms. These mechanisms allow the prop to be adjusted horizontally, ensuring that the structure being supported remains level and stable. It is important to note that safety features and mechanisms may vary depending on the manufacturer and specific design of the steel props. Therefore, it is crucial for construction workers to carefully read and follow the manufacturer's instructions and guidelines to ensure the proper and safe use of steel props.

- Q: Can steel props be used for temporary support during equipment installation?

- Indeed, temporary support during equipment installation can be achieved by utilizing steel props. These props, often adjustable, possess formidable support capabilities, rendering them appropriate for a multitude of construction and installation endeavors. With their stability and ability to endure substantial loads, they emerge as an optimal option for temporary support during equipment installation. Moreover, the installation and adjustment of steel props to the desired height is a straightforward process, ensuring a dependable and secure support system throughout the installation procedure.

- Q: Can steel props be used for supporting temporary fencing around hazardous areas?

- Yes, steel props can be used for supporting temporary fencing around hazardous areas. Steel props are strong and durable, making them suitable for providing stability and security in hazardous environments.

- Q: Can steel props be used in the construction of exhibition halls?

- Yes, steel props can be used in the construction of exhibition halls. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction projects to provide temporary support to structures during construction or renovation. They are particularly useful in exhibition hall construction as they can be easily adjusted to the desired height, allowing for flexible installation and removal of walls, ceilings, and other temporary structures. Steel props are made of high-quality steel, which provides excellent strength and stability. They are designed to withstand heavy loads and provide reliable support, making them suitable for use in large-scale projects such as exhibition hall construction. Additionally, steel props are available in various sizes and weight capacities, allowing for customization to meet specific construction requirements. The use of steel props in exhibition hall construction offers several advantages. Firstly, they provide a cost-effective solution as they can be reused in different projects, reducing the need for frequent purchases. Secondly, their adjustable nature allows for quick and efficient installation, saving time and labor during the construction process. Furthermore, steel props offer versatility as they can support various types of structures, including walls, beams, and temporary stages. However, it is important to consult with structural engineers or construction professionals to ensure that the use of steel props is suitable for the specific exhibition hall project. They can assess the load-bearing requirements and provide guidance on the appropriate size and number of steel props needed for the construction. Additionally, local building codes and regulations should be considered to ensure compliance and safety. In conclusion, steel props can indeed be used in the construction of exhibition halls. Their strength, adaptability, and cost-effectiveness make them a viable option for providing temporary support during the construction or renovation of exhibition spaces.

- Q: What is the maximum lateral load that a steel prop can withstand?

- The maximum lateral load that a steel prop can withstand depends on various factors such as the specific type and size of the prop, its design and construction, as well as the conditions and environment in which it is being used. It is essential to refer to the manufacturer's specifications and guidelines for accurate information regarding the maximum lateral load capacity of a particular steel prop.

Send your message to us

Steel prop & Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords