steel props

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

150 Aluminum Frame Early Dismantling Slab Formwork With Adjustable Prop

Description:

1. Brief introduction

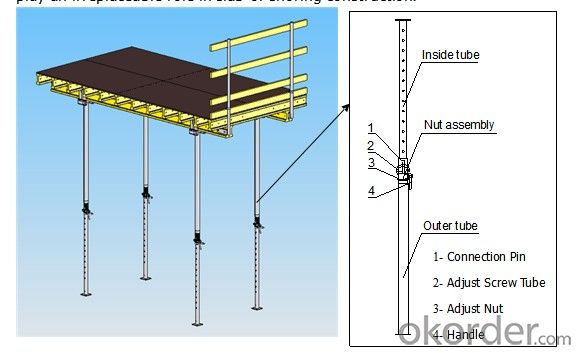

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution. The panel is end product, no assembling on site and it is easily to build, ease of application, more important thing is, the panel is light weight, a dead lift is achieved, save time and effort.

2. Competitive advantage

① Light weight but high load bearing capacity

The panels could be transported by manual work so that it greatly reduces the aggregate cost, accelerates the erection speed, and all in all increases the aggregate benefit.

②Quickly turnover of slab panels

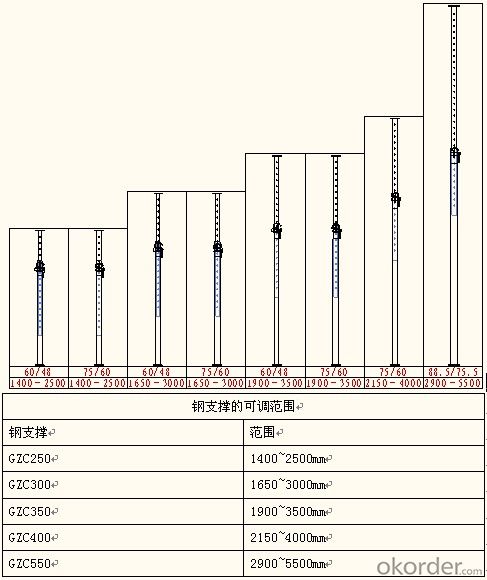

The early dismantling prop system speed up the turnover of the panels, minimize the investment, lower the cost, improve the working efficiency, and shorten the project period under the precondition of keeping the concrete structure and safety uninfluenced, in line with the erection requirement and ensuring the project quality.

③Cost effective with early dismantling prop system.

This early dismantling system is simple, safe and fast, saving at least 50% percent of your construction time.

3. Applications

- Q: Can steel props be used in supporting temporary seating structures?

- Yes, steel props can be used effectively in supporting temporary seating structures. Steel props, also known as adjustable steel props or acrow props, are sturdy and reliable support devices commonly used in construction and temporary structures. Their adjustable height feature allows for flexibility in accommodating different seating levels and their strong load-bearing capacity ensures the stability and safety of the temporary seating structure.

- Q: Are steel props commonly used in power plant construction projects?

- Yes, steel props are commonly used in power plant construction projects. Steel props, also known as adjustable steel props or steel shoring props, are essential temporary supports used to provide stability and support during the construction process. They are commonly used in power plant construction projects to provide temporary support to various structural elements such as beams, columns, and slabs. Steel props are preferred due to their high load-bearing capacity, ease of installation and removal, and adjustable height feature that allows for flexibility in supporting different construction stages. Their robustness and durability make them an ideal choice for power plant construction projects, where safety and stability are of utmost importance.

- Q: Do steel props require any special storage or handling procedures?

- Special storage and handling procedures are necessary for steel props. In construction projects, steel props are commonly utilized to temporarily support structures during construction or renovations. To ensure their durability and safety, it is crucial to adhere to specific procedures when it comes to storing and handling steel props. First and foremost, proper storage is vital in order to shield steel props from environmental factors that may cause corrosion or damage. It is recommended that steel props be stored in a dry and well-ventilated area, away from moisture or direct sunlight. If not in use, they should be kept indoors or covered with a waterproof material. Furthermore, careful handling of steel props is of utmost importance to prevent accidents or injuries. Instead of manually lifting them, it is advisable to use appropriate lifting equipment such as cranes or forklifts when lifting or moving steel props. This ensures that the props are not dropped, which could result in potential damage or injuries. Moreover, it is essential to conduct inspections of steel props both before and after each use. Any indications of damage, such as deformations, cracks, or excessive wear, should be promptly addressed. Damaged steel props should not be used and should be either replaced or repaired to uphold the structural integrity and safety of the construction site. In conclusion, special storage and handling procedures are required for steel props to ensure their durability and safety. By adhering to proper storage techniques, employing careful handling practices, and conducting regular inspections, damage can be prevented and the quality of steel props can be maintained, ultimately contributing to a safe and efficient construction process.

- Q: What are the limitations of using steel props?

- There are several limitations associated with using steel props in construction and temporary support systems. 1. Weight and handling: Steel props can be heavy and difficult to transport, especially when working on higher levels of a building or in confined spaces. The weight can also make them challenging to manipulate and adjust during installation and removal. 2. Limited adjustability: While steel props offer some adjustability, their range may not be sufficient for all applications. Adjusting the height of steel props can be time-consuming and may require additional tools or equipment. 3. Load capacity: Steel props have a limited load-bearing capacity. Depending on the specific type and size of the prop, they may not be able to support heavy loads or withstand excessive forces. This limitation can restrict their use in certain construction projects, especially those requiring extensive structural support. 4. Corrosion: Steel props are prone to corrosion when exposed to moisture, chemicals, or harsh environmental conditions. If not properly maintained or protected, this corrosion can weaken the props over time, reducing their overall strength and stability. 5. Limited structural versatility: Steel props are primarily designed for vertical support and may not be suitable for certain structural configurations or unconventional building layouts. They may not provide adequate stability or alignment in non-standard situations, requiring alternative support systems to be used. 6. Cost: Steel props can be expensive to purchase or rent, especially for long-term projects or when a large number of props are required. The cost of transportation, storage, and maintenance should also be considered when using steel props. 7. Safety concerns: Steel props require proper installation and regular inspections to ensure they are secure and stable. Failure to do so can result in accidents, injuries, or structural damages. Additionally, steel props can pose a tripping hazard if not properly positioned or secured. It is important to carefully assess the specific requirements of a project and consider alternative support systems when necessary to overcome the limitations of using steel props.

- Q: Are steel props suitable for supporting temporary art installations or sculptures?

- Yes, steel props are suitable for supporting temporary art installations or sculptures. Steel is known for its strength, durability, and load-bearing capacity, making it an ideal choice for supporting heavy and intricate artworks. Moreover, steel props can be easily customized to meet the specific requirements of the installation or sculpture. They can be designed to provide stability, balance, and secure placement, ensuring that the artwork remains safely supported throughout its display period. Additionally, steel props can be adjusted in height and angle, allowing for flexibility in positioning the artwork for optimal viewing angles. Overall, steel props offer a reliable and versatile solution for supporting temporary art installations or sculptures, ensuring the safety and longevity of the artwork.

- Q: How do steel props compare to timber beams?

- Steel props and timber beams are both commonly used in construction projects, but they have distinct differences in terms of their properties and applications. Strength and Load-Bearing Capacity: Steel props are known for their superior strength and load-bearing capacity compared to timber beams. Steel is a much stronger material than wood, allowing steel props to support heavier loads and provide more stability and structural integrity. Durability: Steel is highly durable and resistant to environmental factors such as moisture, pests, and rot, making steel props more reliable and long-lasting than timber beams. Timber beams, on the other hand, are prone to decay, warping, and insect infestations, which can compromise their structural integrity over time. Versatility: Steel props offer greater versatility in terms of adjustability and adaptability. They are often telescopic, allowing for easy height adjustment and accommodation of various construction needs. Timber beams, on the other hand, are generally fixed in size and require additional work for modifications. Fire Resistance: Steel is non-combustible and has high fire resistance, making steel props a safer option in case of fire. Timber beams, being a combustible material, can contribute to the spread of fire and pose a higher risk in terms of fire safety. Cost: Steel props are typically more expensive than timber beams, mainly due to the higher material cost and manufacturing process. However, steel props' durability and longer lifespan may result in cost savings over time due to reduced maintenance and replacement needs. Environmental Impact: Timber beams are considered a more sustainable and environmentally friendly option compared to steel props. Timber is a renewable resource, while steel production requires significant energy and can generate more carbon emissions. However, the environmental impact depends on factors such as sourcing practices and responsible forestry management. Overall, steel props offer superior strength, durability, adjustability, fire resistance, and long-term cost-effectiveness. Timber beams, while more sustainable and potentially cost-effective upfront, may require more maintenance and are less suitable for heavy load-bearing applications. The choice between steel props and timber beams ultimately depends on the specific project requirements, budget constraints, and environmental considerations.

- Q: Can steel props be used for temporary support in telecommunications cable installation?

- Yes, steel props can be used for temporary support in telecommunications cable installation. Steel props provide strong and stable support for cables, ensuring the safety and proper installation of the telecommunications infrastructure.

- Q: Can steel props be used for temporary support in underground parking structures?

- Yes, steel props can be used for temporary support in underground parking structures. Steel props are commonly used in construction to provide temporary support during the construction process. They are strong and durable, making them suitable for supporting the weight and load of an underground parking structure until permanent support systems are installed.

- Q: Are steel props adjustable with a single person?

- Yes, steel props can be adjusted by a single person. They are designed with an adjustable mechanism that allows one person to easily change the height to fit various requirements.

- Q: Can steel props be used in mining and tunneling projects?

- Yes, steel props can be used in mining and tunneling projects. Steel props provide structural support and stability to underground excavations, helping to prevent collapses and ensure the safety of workers. They are commonly used in various mining and tunneling operations due to their strength, durability, and ability to withstand high loads and pressures.

Send your message to us

steel props

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords