steel props of C

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

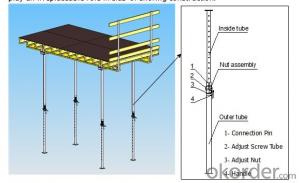

150 Aluminum Frame Early Dismantling Slab Formwork With Adjustable Prop

Description:

1. Brief introduction

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution. The panel is end product, no assembling on site and it is easily to build, ease of application, more important thing is, the panel is light weight, a dead lift is achieved, save time and effort.

2. Competitive advantage

① Light weight but high load bearing capacity

The panels could be transported by manual work so that it greatly reduces the aggregate cost, accelerates the erection speed, and all in all increases the aggregate benefit.

②Quickly turnover of slab panels

The early dismantling prop system speed up the turnover of the panels, minimize the investment, lower the cost, improve the working efficiency, and shorten the project period under the precondition of keeping the concrete structure and safety uninfluenced, in line with the erection requirement and ensuring the project quality.

③Cost effective with early dismantling prop system.

This early dismantling system is simple, safe and fast, saving at least 50% percent of your construction time.

3. Applications

- Q: Can steel props be used for temporary support in wind tunnel construction?

- Yes, steel props can be used for temporary support in wind tunnel construction. Steel props are known for their strength and durability, making them suitable for providing temporary support during the construction process. They are capable of withstanding heavy loads and can be easily adjusted to the desired height, allowing for flexibility in the wind tunnel construction. Additionally, steel props are resistant to adverse weather conditions, including wind, which is particularly important for wind tunnel construction. Therefore, steel props are a reliable choice for temporary support in wind tunnel construction.

- Q: Can steel props be used for supporting temporary bridges over roadways?

- Yes, steel props can be used for supporting temporary bridges over roadways. Steel props are strong and durable, making them suitable for providing temporary structural support for bridges.

- Q: What are the potential environmental impacts of using steel props?

- The potential environmental impacts of using steel props include the extraction of raw materials (iron ore and coal), which can lead to habitat destruction and air and water pollution. The manufacturing process of steel props also consumes large amounts of energy and emits greenhouse gases. Additionally, the disposal of steel props at the end of their lifespan can contribute to landfill waste. However, steel props can be recycled, which can mitigate some of these impacts.

- Q: Can steel props be used for temporary support in dam construction?

- Yes, steel props can be used for temporary support in dam construction. Steel props provide strong and reliable support, making them suitable for various construction projects, including dams. They can withstand heavy loads and provide stability during the construction process.

- Q: Can steel props be used for supporting temporary exhibition booths or stands?

- Yes, steel props can be used for supporting temporary exhibition booths or stands. Steel props are strong and durable, making them a reliable choice for providing stability and support to temporary structures. They can easily be adjusted to the desired height and provide a secure base for exhibition booths or stands.

- Q: How do you prevent unauthorized access to steel props on construction sites?

- To ensure the safety of workers and maintain the project's integrity, it is crucial to prevent unauthorized access to steel props on construction sites. Here are several steps that can be taken to achieve this: 1. Establish a secure perimeter: Utilize fences and barriers to create a secure boundary around the construction site. Clearly mark restricted areas with signs indicating the prohibition of unauthorized entry. 2. Implement access control measures: Enforce strict access control by using controlled entry points and identification systems. This can involve the use of access cards, biometric scanners, or security personnel to regulate entry to the site. 3. Install surveillance systems: Strategically place CCTV cameras throughout the construction site to monitor and record activities, particularly in areas where steel props are stored or used. Maintain and regularly check the functioning of the surveillance system. 4. Ensure adequate lighting: Install lighting systems that illuminate all areas of the construction site, especially those where steel props are stored. Sufficient lighting can make it more difficult for unauthorized individuals to enter unnoticed. 5. Secure storage areas: Use robust locking mechanisms, such as padlocks or combination locks, to secure areas where steel props are stored. Regularly inspect and replace locks if needed. 6. Employ security personnel: Assign trained security personnel to patrol the construction site and monitor access points. They should be prepared to respond promptly and effectively to any unauthorized access attempts. 7. Conduct regular inventory checks: Regularly inspect steel props to ensure they have not been tampered with or stolen. Maintain a record of all props and their locations to quickly identify any discrepancies. 8. Provide employee training: Educate all construction site workers on the significance of preventing unauthorized access to steel props. Foster a culture of security and vigilance among the workforce. 9. Install alarm systems: Set up alarms that can be triggered by unauthorized entry attempts. These alarms should be loud and easily audible to alert security personnel or nearby workers. 10. Regularly inspect the site: Conduct routine inspections of the construction site to identify any vulnerabilities or weaknesses in the security measures. Continuously improve security protocols based on these inspections. By implementing these preventive measures, construction site managers can greatly reduce the risk of unauthorized access to steel props, ensuring the safety of workers and the successful completion of the project.

- Q: Do steel props require any special tools for installation and adjustment?

- Yes, steel props typically require special tools such as spanners or wrenches for installation and adjustment. These tools are used to tighten and loosen the adjustable components of the props, allowing for proper installation and adjustment according to the required height and load-bearing capacity.

- Q: How do you calculate the required height of steel props for a project?

- To calculate the required height of steel props for a project, you need to consider several factors. First, you need to determine the load that the props will be supporting. This includes the weight of any building materials, equipment, or people that will be on the supported structure. You will also need to account for any additional loads such as wind or snow. Next, you need to determine the spacing of the props. This will depend on the type of structure being supported and the load distribution. Generally, the props should be evenly spaced to ensure uniform support. Once you have determined the load and spacing, you can calculate the required height of the props. This can be done using engineering calculations or consulting relevant codes and standards. The height should be sufficient to withstand the calculated load without excessive deflection or stress. It is also important to consider any potential adjustments or fine-tuning that may be needed during construction. This could include factors like the settling of the structure or the need to level the props. Overall, calculating the required height of steel props for a project requires careful consideration of the load, spacing, and potential adjustments. It is recommended to consult with a structural engineer or refer to appropriate guidelines to ensure accurate calculations.

- Q: How do you ensure proper alignment when using multiple steel props?

- Achieving proper alignment when using multiple steel props requires a series of essential measures: 1. Commence by accurately measuring and marking the designated positions for the steel props. This technique guarantees a consistent distance between the props and guarantees their accurate alignment. 2. Prior to installing the steel props, confirm that the ground or foundation where they will be placed is both level and stable. Any irregularities or instability in the ground can lead to misalignment of the props. 3. During the insertion process, ensure that the props are fully extended and securely locked in place. This precautionary measure prevents any movement or displacement once the load is applied. 4. Employ either a spirit level or laser level to assess the vertical alignment of the props. This method guarantees their perfect upright position without any leaning in any direction. 5. In the case of using multiple props in parallel, utilize string lines or laser levels to examine the horizontal alignment. This practice ensures a straight line without any sagging or bending. 6. Regularly inspect the props throughout the construction process to ensure they remain properly aligned. Over time, the load or other factors may cause slight shifts or movements; therefore, it is crucial to constantly monitor and readjust as necessary. By adhering to these steps, you can secure the proper alignment of multiple steel props, providing the necessary support and stability for your construction project.

- Q: What is the maximum spacing between steel props?

- The maximum spacing between steel props depends on various factors such as the load capacity of the props, the height and width of the structure being supported, and the specific requirements of the construction project. However, as a general guideline, the maximum spacing between steel props is typically determined by engineering calculations and recommendations provided by the manufacturer or relevant industry standards. The purpose of steel props is to provide temporary support during construction or renovation work, ensuring the stability and integrity of the structure. Therefore, it is crucial to ensure that the props are spaced at appropriate intervals to effectively distribute the load and prevent any potential structural failures or collapses. To determine the maximum spacing between steel props, engineers consider the weight and distribution of the load being supported, as well as the properties of the material being used. They also take into account the height and width of the structure, the type of prop being used, and any additional support or reinforcement measures in place. It is important to consult with a qualified structural engineer or follow the guidelines provided by the manufacturer to determine the maximum spacing between steel props for a specific project. By doing so, one can ensure the safety and stability of the structure being supported.

Send your message to us

steel props of C

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords