steel props of lift

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

suspended slab formwork

slab form work

concrete slab formwork

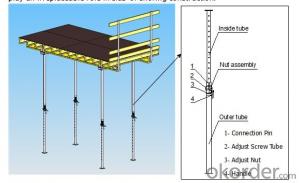

150 Aluminum Frame Early Dismantling Slab Formwork With Adjustable Prop

Description:

1. Brief introduction

Especially for projects with a large number of similar applications and open facades, Alu-slab system is the right solution. The panel is end product, no assembling on site and it is easily to build, ease of application, more important thing is, the panel is light weight, a dead lift is achieved, save time and effort.

2. Competitive advantage

① Light weight but high load bearing capacity

The panels could be transported by manual work so that it greatly reduces the aggregate cost, accelerates the erection speed, and all in all increases the aggregate benefit.

②Quickly turnover of slab panels

The early dismantling prop system speed up the turnover of the panels, minimize the investment, lower the cost, improve the working efficiency, and shorten the project period under the precondition of keeping the concrete structure and safety uninfluenced, in line with the erection requirement and ensuring the project quality.

③Cost effective with early dismantling prop system.

This early dismantling system is simple, safe and fast, saving at least 50% percent of your construction time.

3. Applications

- Q:Can steel props be used in the installation of temporary telecommunications infrastructure?

- Indeed, temporary telecommunications infrastructure installations can make use of steel props. In construction, steel props are frequently employed to offer temporary support for different structures, including telecommunications infrastructure. These props can be adjusted to different heights and are effortlessly installed and dismantled, making them ideal for temporary installations. By using steel props, the stability and safety of the installation process are guaranteed, enabling proper positioning and alignment of the telecommunications equipment. Furthermore, steel props possess strength and durability, enabling them to withstand the weight and load of the infrastructure. All in all, steel props prove to be an efficient and trustworthy solution for supporting temporary telecommunications infrastructure installations.

- Q:Can steel props be used for temporary support in wind turbine installation?

- Yes, steel props can be used for temporary support in wind turbine installation. Steel props are strong and durable, making them suitable for providing the necessary support during the installation process.

- Q:Can steel props be used in road construction?

- Yes, steel props can be used in road construction. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to support and temporarily hold structures or formwork during construction projects, including road construction. In road construction, steel props are often used to support and stabilize temporary structures such as scaffolding, formwork, or concrete barriers. They are also used to provide additional support to excavated areas or trenches during the construction of road foundations or underground utilities. Steel props are preferred in road construction due to their strength, durability, and adjustability. They can be easily adjusted to the required height, allowing for flexibility in different construction scenarios. Additionally, steel props are lightweight and portable, making them efficient and cost-effective in road construction projects. Moreover, steel props offer a high load-bearing capacity, ensuring the stability and safety of the construction site. They can withstand heavy loads and provide reliable support to the structures or formwork being used in road construction. Overall, steel props are a valuable tool in road construction, providing temporary support and stability to various structures or formwork used in the construction process.

- Q:Can steel props be used in the construction of temporary bridges?

- Certainly! Steel props, also referred to as adjustable steel props or steel shore props, have the capability to be employed in the creation of temporary bridges. These versatile props are frequently utilized in construction endeavors to offer temporary support to structures like walls, beams, and floors. Due to their ability to be easily adjusted to varying heights, they are particularly well-suited for temporary bridge construction. Temporary bridges are typically designed for rapid assembly and disassembly, making steel props an exceptional option for providing support to bridge components during the construction process. The adaptable nature of steel props allows for flexibility in accommodating different bridge heights and spans. They possess the capacity to endure substantial loads and contribute stability to the temporary bridge structure, ensuring the safety of both workers and materials throughout construction. Moreover, steel props possess the added advantage of reusability. Once the temporary bridge is dismantled, the steel props can be effortlessly disassembled, stored, and employed in future construction projects. This characteristic makes them a cost-effective solution for temporary bridge construction, as they can be utilized multiple times, thereby reducing the necessity for new support systems. To sum up, steel props are indeed suitable for use in temporary bridge construction. Their adjustability, load-bearing capability, and reusability make them an efficient choice for providing temporary support and stability to bridge components throughout the construction process.

- Q:Can steel props be used for supporting temporary walkways or ramps?

- Temporary walkways or ramps can be supported using steel props. These props, alternatively known as adjustable steel props or steel acrow props, are commonly utilized in construction projects to provide temporary bracing and support structures. They possess the capacity to bear loads and maintain stability, making them suitable for the task of supporting walkways or ramps. The height of steel props can be adjusted to the desired level in order to adequately support the temporary structure. With a variety of sizes and weight capacities available, it is simple to select the appropriate prop for the specific application. Furthermore, steel props are constructed from robust and durable materials, ensuring their ability to endure the weight and pressure exerted by individuals utilizing ramps or walking on walkways. Proper installation and adherence to safety guidelines are essential when employing steel props to support temporary walkways or ramps. The props need to be securely positioned and evenly distributed to create a stable and level surface. Regular inspections and maintenance are also necessary to ensure the props remain in optimal condition and continue to provide sufficient support. All in all, steel props offer a dependable and efficient solution for supporting temporary walkways or ramps, delivering the necessary strength and stability required for safe usage.

- Q:Can steel props be used in temporary support of overhead cranes?

- Yes, steel props can be used in temporary support of overhead cranes. Steel props are widely used in construction and engineering projects to provide temporary support for various structures, including overhead cranes. They are commonly used when the existing support structure is insufficient or needs additional reinforcement. Steel props are highly durable and can withstand heavy loads, making them suitable for supporting overhead cranes. However, it is essential to ensure that the steel props are installed correctly, following the manufacturer's guidelines and adhering to safety regulations, to ensure the stability and safety of the crane and the surrounding area.

- Q:What are the different types of steel prop accessories available?

- There are several different types of steel prop accessories available, each serving a specific purpose in construction and temporary support applications. Some of the most common types include: 1. Prop sleeves: These are cylindrical steel tubes that are used to extend the length of steel props. They are often used when additional height is needed to support higher loads or to accommodate uneven surfaces. 2. Prop nuts: These are threaded nuts that are used to adjust the height of steel props. They are typically placed at the top of the prop and tightened or loosened to achieve the desired height. Prop nuts also help to secure the prop in place and prevent it from slipping. 3. Prop pins: These are steel pins that are used to lock the prop nuts in place once the desired height is achieved. They are inserted through holes in the prop sleeve and prop nut to prevent any accidental adjustments or movements. 4. Base plates: These are flat steel plates that are placed at the bottom of steel props to provide a stable and even surface for weight distribution. Base plates also help to prevent the prop from sinking into soft or unstable ground. 5. U-heads: These are U-shaped steel brackets that are attached to the top of steel props. They provide a larger surface area for supporting beams or other structural elements. U-heads are commonly used in formwork and shoring applications. 6. Prop spigots: These are steel connectors that are used to join multiple steel props together horizontally. They allow for the creation of longer support structures and are often used in applications that require a continuous load-bearing surface. 7. Prop couplers: These are steel connectors that are used to join multiple steel props together vertically. They are typically used when additional height is needed and allow for easy and secure connection between props. 8. Prop jacks: These are mechanical devices that are used to adjust the height of steel props with greater precision. They typically consist of a threaded rod and a handle, allowing for easy height adjustments by turning the handle. These are just a few examples of the different types of steel prop accessories available. Depending on the specific requirements of a construction project, there may be additional accessories or variations of the ones mentioned above.

- Q:Can steel props be used in temporary structures?

- Yes, steel props can be used in temporary structures. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction projects to support and stabilize temporary structures such as scaffolding, formwork, and falsework. These props are made of high-strength steel and are designed to be adjustable in height, allowing them to provide the necessary support for various temporary structures. Steel props are durable, reliable, and have a high load-bearing capacity, making them suitable for use in temporary structures where stability and safety are crucial.

- Q:Are steel props adjustable for supporting irregularly shaped structures?

- Steel props have the ability to be adjusted, making them suitable for supporting structures with irregular shapes. They are commonly used in construction to stabilize and support structures during renovation or construction work. These props, also known as adjustable acrow props or shore props, consist of two main components: an inner tube and an outer tube. The threaded collar allows for adjustment of the props. The adjustability of the steel props makes them ideal for accommodating the specific requirements of different structures. This is particularly beneficial when dealing with irregularly shaped structures, as it allows the props to be tailored to fit the unique angles and dimensions of the construction. Additionally, steel props often come with various accessories such as swivel heads or forks. These accessories can be attached to the top of the props, giving them the ability to support beams, walls, or other structural elements with irregular shapes. In conclusion, steel props are extremely versatile and can be adjusted to provide stable support for structures of various types, regardless of their irregular shapes.

- Q:How do you protect steel props from damage during construction activities?

- There are various measures that can be implemented to safeguard steel props from harm during construction activities: 1. Optimal storage: Allocate a specific area for storing steel props that shields them from external elements like rain, snow, and direct sunlight. This will avert corrosion and other types of damage. 2. Routine maintenance: Regularly examine the props for signs of deterioration. Promptly replace any impaired or weakened components to avoid structural failure during construction. 3. Utilize protective covers: When not in use, cover the steel props with caps or covers to shield them from dust, debris, and potential sources of harm. 4. Handle with caution: Train construction workers in proper handling techniques to prevent accidental harm. Refrain from dropping or throwing the props, and employ suitable lifting equipment when necessary. 5. Avoid overburdening: Ensure that the steel props are not exposed to excessive weight or loads that surpass their specified capacity. This will prevent structural failure and damage to the props. 6. Employ appropriate support: When utilizing the steel props to support structures, guarantee that they are correctly aligned and supported by adequate foundations or bases. This will distribute the load evenly and diminish the risk of damage. 7. Regular inspections: Conduct periodic inspections of the steel props throughout the construction process to detect any potential issues. This will enable timely repairs or replacements, ensuring the props remain in good condition. By adhering to these guidelines, construction activities can be executed safely, and the steel props can be shielded from harm, thereby ensuring their durability and effectiveness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

steel props of lift

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords