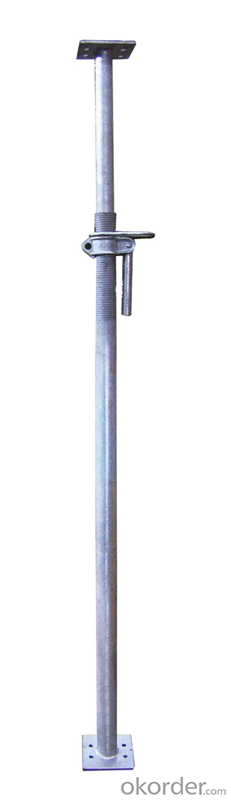

Construction Adjustable Steel Shoring Prop

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Props:

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q: Can steel props be used in formwork systems?

- Yes, steel props can be used in formwork systems. Steel props are vertical support structures that are adjustable in height and provide temporary support to formwork during construction. They are commonly used in formwork systems to support beams, slabs, walls, and other structural elements. Steel props are strong and durable, making them suitable for supporting heavy loads in construction projects. They can be easily adjusted and secured in place, allowing for flexibility in formwork design. Additionally, steel props can be reused multiple times, making them a cost-effective solution for formwork support. Overall, steel props are a reliable and commonly used component in formwork systems.

- Q: How do you determine the appropriate size of a steel prop for a specific job?

- In order to determine the appropriate size of a steel prop for a specific job, there are several factors that need to be taken into consideration. First and foremost, it is crucial to evaluate the load that the steel prop will be required to support. This involves considering the weight of the structure or material that will be supported, as well as any additional loads or forces that may be applied to the prop throughout the job. Following that, the height or span that the steel prop needs to cover must be accounted for. The greater the distance that needs to be supported, whether it be in terms of height or width, the larger and stronger the prop will need to be in order to ensure sufficient stability and support. Moreover, the material and construction of the steel prop should not be overlooked. Different types of steel props possess varying load capacities and capabilities, making it imperative to select one that is suitable for the specific requirements of the job. Furthermore, it is advisable to consult local regulations, codes, and standards to ensure compliance and safety. These guidelines may outline specific prerequisites or recommendations regarding the size and capacity of steel props for different types of jobs. Lastly, seeking guidance from a structural engineer or an experienced professional in working with steel props can offer valuable insights and recommendations. They can thoroughly analyze the specific demands of the job, assess the load and span, and provide expert advice on the appropriate size of the steel prop to guarantee safety and efficiency.

- Q: Can steel props be used in marine construction projects?

- Yes, steel props can be used in marine construction projects. Steel props, also known as adjustable steel props or steel shore props, are commonly used in construction projects to support vertical loads. They are adjustable in height and can be used to provide temporary support during the construction of marine structures such as piers, docks, and bridges. Steel props are made of high-quality steel and have the strength and durability necessary to withstand the harsh marine environment. They can be used to support various structures and components, including formwork, scaffolding, and temporary supports for concrete pouring. Their adjustable height feature allows for easy customization and adaptation to different marine construction requirements. Furthermore, steel props can be easily installed and dismantled, making them suitable for temporary applications in marine construction projects. They provide stability and safety to the construction site, ensuring that structures are properly supported during the construction process. Additionally, steel props are resistant to corrosion, which is a crucial factor in marine construction where exposure to saltwater and other corrosive elements is common. In conclusion, steel props are a viable option for marine construction projects. Their strength, durability, adjustability, and resistance to corrosion make them suitable for supporting various structures and components in the marine environment.

- Q: Can steel props be used for supporting temporary military structures?

- Yes, steel props can be used for supporting temporary military structures. Steel props, also known as adjustable steel props or steel shore props, are commonly used in construction to support temporary structures such as formwork, scaffolding, and shoring systems. These props are made of high-grade steel, which provides strength, stability, and durability. In the military context, temporary structures are often erected for various purposes, including command centers, field hospitals, barracks, and storage facilities. Steel props can be an ideal choice for supporting these structures due to their load-bearing capacity and adjustability. Steel props can support heavy loads and can be easily adjusted to the desired height. They can be extended or retracted according to the specific requirements of the military structure. This adjustability feature allows for flexibility in adapting to different terrain or ground conditions, ensuring stability and safety. Furthermore, steel props are relatively lightweight and easy to transport, making them suitable for military operations where mobility is crucial. They can be quickly assembled and disassembled, allowing for efficient deployment and relocation of temporary structures as needed. Additionally, steel props are resistant to corrosion and adverse environmental conditions, making them suitable for military deployments in various climates and terrains. They can withstand harsh weather conditions such as strong winds, heavy rain, and extreme temperatures. In conclusion, steel props can indeed be used for supporting temporary military structures. Their strength, adjustability, mobility, and resistance to environmental factors make them a reliable choice for providing the necessary support and stability required in military operations.

- Q: Can steel props be used for temporary support in oil refinery projects?

- Steel props are a viable option for temporary support in oil refinery projects. In the realm of construction, steel props are frequently employed to offer temporary support to structures or equipment. Within oil refinery projects, where hefty machinery and equipment are involved, steel props can be utilized to provide supplementary support during construction, maintenance, or repair endeavors. These props boast adjustable heights and are constructed from robust and enduring steel, rendering them appropriate for sustaining substantial loads. Their installation, dismantling, and repositioning can be easily achieved as per requirements, granting flexibility within the project. Steel props deliver stability and safety, rendering them an ideal selection for temporary support in oil refinery projects.

- Q: Can steel props be used in the installation of temporary lighting or sound equipment?

- Yes, steel props can be used in the installation of temporary lighting or sound equipment. Steel props, also known as adjustable steel props or steel shoring props, are commonly used in construction to support temporary structures or loads. They are designed to provide stability and strength, making them suitable for a wide range of applications including the installation of temporary lighting or sound equipment. Steel props are adjustable in height, allowing for precise positioning and alignment of equipment. They can be easily extended or retracted to accommodate different heights or uneven surfaces. Additionally, their robust construction ensures they can withstand the weight and pressure of lighting or sound equipment, providing a secure and stable support. Moreover, steel props are easy to install and dismantle, making them ideal for temporary setups where equipment needs to be quickly set up or removed. They are often used in events such as concerts, festivals, or theater productions where lighting and sound equipment are frequently required to be installed and removed within a short period of time. In summary, steel props are a reliable and versatile solution for the installation of temporary lighting or sound equipment. Their adjustable height, strength, stability, and ease of use make them well-suited for such applications.

- Q: Are steel props resistant to corrosion and rust?

- Indeed, resistance to corrosion and rust is a characteristic commonly associated with steel props. Steel, an alloy mainly consisting of iron and carbon, is renowned for its robustness and endurance. Nevertheless, steel can still undergo corrosion and rust in specific circumstances, such as when exposed to moisture, chemicals, or extreme temperatures. In order to augment the steel props' ability to withstand corrosion, they are frequently subjected to protective coatings or galvanization. These coatings serve as a barrier, obstructing the access of water and oxygen to the steel surface, thus hindering the onset of corrosion. Additionally, regular maintenance and inspection are crucial to ensure the continual resilience against corrosion and rust.

- Q: How much space should be filled in the steel pipe support of 70cm thick ground floor?

- The steel tube support frame is installed on the hanging basket and the common external wall construction and installation basket method. Only in the steel pipe bracket installation basket should pay attention to avoid the steel pipe bracket, to avoid the influence of the steel bracket of the electric basket rise and fall. Thus affecting the normal operation of the electric basket

- Q: How do steel props contribute to the overall cost of a construction project?

- Steel props, also referred to as adjustable steel props or scaffolding props, play a crucial role in the total expenses of a construction project. These temporary structural supports are utilized to provide stability and load-bearing capacity for various construction activities, including formwork, concrete pouring, and shoring. The rental or purchase costs of steel props are one of the primary ways they affect the overall expenses. Construction projects often require a considerable number of props, and these expenses can accumulate rapidly. However, it is important to note that despite the initial investment appearing substantial, steel props are durable and reusable, making them a cost-effective solution in the long term. Moreover, steel props impact the total expenses by reducing labor costs. Their adjustable height feature allows for quick and effortless installation, saving significant time and effort compared to traditional wooden supports. This efficiency results in reduced labor expenses as fewer workers are needed to set up and dismantle the props. Steel props also contribute to safety on construction sites, which ultimately affects the project's overall expenses. By providing sturdy support, they help prevent accidents and structural failures, reducing the chances of costly damages or injuries. Furthermore, their load-bearing capacity ensures the stability of formwork and other construction elements, minimizing the need for repairs or rework, which can be time-consuming and expensive. Additionally, steel props contribute to the total expenses by offering flexibility and adaptability. Their adjustable nature allows for easy modifications to accommodate different heights and load requirements. This versatility eliminates the necessity for custom-made supports and costly alterations, ultimately reducing project costs. Lastly, steel props contribute to cost savings through their versatility and reusability. They can be used across multiple projects, minimizing the need for frequent repurchasing or rental expenses. Additionally, their durability ensures a longer lifespan, reducing maintenance and replacement costs. In conclusion, while steel props may require initial expenses, their cost-saving advantages are significant. From reducing labor costs and enhancing safety to offering flexibility and reusability, steel props play a crucial role in the overall expenses of a construction project. Their efficiency and durability make them a valuable investment, ultimately leading to improved project outcomes and financial savings.

- Q: How do you maintain and clean steel props?

- To ensure the maintenance and cleanliness of steel props, there are several crucial steps that can be taken. First and foremost, it is imperative to conduct regular inspections on the steel props in order to identify any signs of damage or wear. This can be achieved by visually examining the props and thoroughly checking for cracks, dents, or rust. If any issues are discovered, it is crucial to address them promptly to prevent further harm and guarantee the safety of the props. To cleanse the steel props, a comprehensive cleaning process can be implemented. Start by eliminating any loose dirt or debris using a brush or compressed air. Following that, prepare a solution consisting of warm water and mild detergent. Dip a clean cloth or sponge into the solution and delicately scrub the props, paying particular attention to stubborn stains or dirt. Subsequently, rinse the props thoroughly with clean water to eliminate any residual soap. After the cleaning process, it is essential to ensure that the steel props are completely dry to prevent rust formation. Utilize a clean towel or allow the props to air dry in a well-ventilated area. Once dry, it is advisable to apply a thin layer of lubricant or rust inhibitor to provide additional protection against corrosion. In addition to regular cleaning, proper storage of the steel props is crucial for their maintenance. Store them in a dry and well-ventilated location, away from moisture and extreme temperatures. If the props will not be used for an extended period, it is recommended to apply a thicker layer of rust inhibitor and wrap them in a protective covering. By adhering to these maintenance and cleaning practices, the steel props can be kept in optimal condition, ensuring their longevity and safety during usage.

Send your message to us

Construction Adjustable Steel Shoring Prop

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords