Adjustable Steel Prop - Vertical Structure Support System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

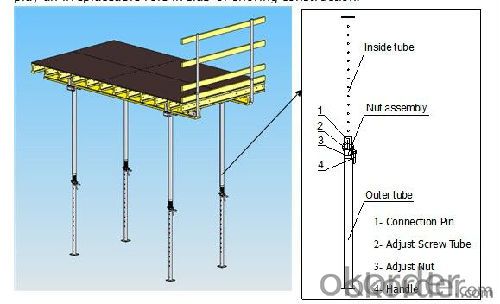

1. Structure of Adjustable Steel Prop

A vertical support system widely used in construction of slab or shoring. The prop has simple structure. It is easy to operation and has perfect adjustment to each individual job site requirement, all these features decide that the props play an irreplaceable role in slab or shoring construction.

2. Main Features of Adjustable Steel Prop

① Simple structure, easy operation.

As the above picture shown, the prop has very simple structure. The height of prop is adjustable by means of the relative position of inside tube and outer tube. And the light adjustment will be achieved by rotating adjust nut. It is very easy to operate for every labor.

②Reasonable load-bearing capacity.

The prop is mainly used for supporting slab formwork, especially for table formwork, its load-bearing capacity is undoubted important to be construction safety. The props have two series according to different load-bearing capacity: 30KN per set and 20KN per set with maximum height. Usually, we take 2 times safety factors in formwork design.

3. Adjustable Steel Prop Images

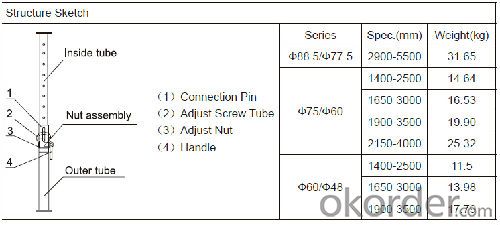

4. Adjustable Steel Prop Specification

5. FAQ of Adjustable Steel Prop

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Adjustable Steel Prop, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Adjustable Steel Prop, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:What are the different surface finishes available for steel props?

- There are several different surface finishes available for steel props, each offering unique properties and benefits. Some of the most common surface finishes for steel props include: 1. Galvanized finish: This is one of the most popular surface finishes for steel props. Galvanization involves coating the steel prop with a layer of zinc, providing excellent corrosion resistance and durability. Galvanized steel props are suitable for use in harsh environments, such as construction sites or areas with high humidity. 2. Powder-coated finish: Powder coating is a method where a dry powder is electrostatically applied to the steel prop and then cured under heat, creating a hard and durable finish. This finish not only provides protection against corrosion but also offers a wide range of color options, allowing for customization and aesthetic appeal. 3. Painted finish: Painting the steel props is another common surface finish. Paint provides a protective layer against corrosion and can also be used to indicate different load-bearing capacities or identify the props for specific applications. The paint used for steel props is typically a high-quality, corrosion-resistant paint designed for outdoor use. 4. Bare or untreated finish: In some cases, steel props may be left untreated or bare. This means that the steel prop is not coated or painted in any way. While this finish does not provide any significant corrosion resistance, it is often chosen for applications where a specific surface treatment is not required, or where a temporary use is anticipated. It is worth noting that the choice of surface finish for steel props depends on the specific application, the surrounding environment, and the desired level of protection against corrosion. It is essential to consider these factors and consult with professionals to determine the most suitable surface finish for your steel props.

- Q:Can steel props be used for supporting retaining walls?

- Yes, steel props can be used for supporting retaining walls. Steel props offer high load-bearing capacity and stability, making them suitable for providing temporary or permanent support to retaining walls. They can effectively withstand the pressure exerted by the soil and ensure the stability and integrity of the walls.

- Q:Are steel props suitable for supporting heavy structures?

- Yes, steel props are suitable for supporting heavy structures. Steel is known for its strength and durability, making it an ideal material for supporting heavy loads. Steel props, also known as steel shoring or steel shores, are commonly used in construction projects to provide temporary support to structures during construction or renovation. They are adjustable and can be easily extended or retracted to accommodate various heights and weight requirements. Additionally, steel props are designed to distribute the load evenly, ensuring stability and preventing any sagging or collapsing of the structure. Overall, steel props are a reliable and effective solution for supporting heavy structures.

- Q:What are the alternatives to steel props?

- Some alternatives to steel props include adjustable telescopic props made of aluminum or fiberglass, modular shoring systems, hydraulic shoring systems, and timber props.

- Q:What are the typical load testing procedures for steel props?

- The load testing procedures for steel props typically encompass the following stages: 1. Initial inspection: Before commencing load testing, it is essential to conduct a thorough examination of the steel props to detect any signs of damage or wear. This entails inspecting for cracks, deformations, corrosion, and other structural issues that may jeopardize the props' integrity. 2. Load calculation: The load testing procedure initiates with the determination of the maximum load capacity that the steel props are designed to withstand. This calculation considers variables such as prop type, dimensions, material strength, and relevant safety codes or standards. 3. Test setup: Once the load calculation is finalized, the subsequent step involves arranging the testing environment. This necessitates securely positioning the props and ensuring proper support to prevent any inadvertent collapse or movement during the test. 4. Load application: Hydraulic jacks, weights, or other suitable equipment are employed to gradually apply load to the steel props. The load is incrementally increased until it reaches the predetermined maximum load specified in the load calculation. 5. Load measurement: Throughout the testing process, precise load measurements are taken at regular intervals to monitor the behavior of the steel props. This encompasses measuring the load distribution across the props and any deflection or displacement that may transpire. 6. Testing duration: Typically, the load is maintained for a specific duration to allow for observation and assessment of the props' performance under sustained load conditions. The duration may vary depending on the specific requirements and standards applicable to the props being tested. 7. Result assessment: Upon completion of the load testing, the collected data and observations are analyzed to evaluate the performance of the steel props. This entails assessing factors such as deflection, stability, and structural integrity, as well as comparing the test results against applicable safety standards or regulations. 8. Report generation: A comprehensive report is usually prepared, documenting the load testing procedures, results, and any relevant observations or recommendations. This report serves as a record of the testing process and provides valuable information for decision-making concerning the use and safety of the steel props.

- Q:Are steel props suitable for supporting concrete slabs or beams?

- Yes, steel props are suitable for supporting concrete slabs or beams. Steel props provide adjustable and reliable support, allowing for the proper distribution of weight and load-bearing capacity. They are commonly used in construction projects to provide temporary support during the pouring and curing process of concrete slabs or beams. Steel props offer stability, strength, and flexibility, making them an ideal choice for supporting such structures.

- Q:How do you prevent steel props from sinking in wet soil?

- To prevent steel props from sinking in wet soil, there are a few strategies you can employ: 1. Increase the surface area: One effective method is to utilize larger steel plates or base plates at the bottom of the props. These plates should be wider than the props themselves, spreading the load over a larger area and reducing the risk of sinking. 2. Use adjustable props: Consider using adjustable steel props that can be extended or shortened as needed. This allows you to adjust the height of the props to accommodate the varying soil conditions, ensuring they remain stable and secure. 3. Add additional support: If the soil is extremely wet or unstable, it may be necessary to provide additional support to the steel props. This can be achieved by driving wooden or steel beams into the ground at an angle, creating a diagonal brace that provides extra stability. 4. Install a stable base: Prior to installing the props, it is crucial to prepare a stable base in the wet soil. This can be achieved by excavating the area and replacing the wet soil with a layer of compacted gravel or crushed stone. These materials provide a solid and stable foundation for the props. 5. Implement dewatering techniques: If the soil remains consistently wet, implementing dewatering techniques can help reduce the moisture content. This can be achieved through methods such as installing drainage pipes or using pumps to remove excess water from the area. By reducing the water content in the soil, you can improve its stability and prevent the steel props from sinking. Remember, it is essential to consult with a structural engineer or construction professional to assess the specific soil conditions and determine the most suitable solution to prevent steel props from sinking in wet soil.

- Q:Can steel props be used to support roof structures?

- Yes, steel props can be used to support roof structures. Steel props, also known as adjustable steel props or scaffolding props, are commonly used in construction and renovation projects to support various structures, including roof structures. These props are adjustable in height, allowing them to be set at the desired level to provide support to the roof during construction or repair work. Steel props are typically made from high-quality steel, making them strong and capable of withstanding heavy loads. They are also easy to install and dismantle, making them a convenient and reliable choice for providing temporary support to roof structures. Overall, steel props are a popular and effective solution for supporting roof structures in construction projects.

- Q:Can steel props be used for temporary bridges or walkways?

- Yes, steel props can be used for temporary bridges or walkways. Steel props are sturdy and durable, making them suitable for supporting the weight of people and vehicles on temporary structures such as bridges or walkways. They provide excellent structural support and can be easily adjusted to the required height. Additionally, steel props are versatile and can be used in various construction projects, including temporary structures. Their strength and reliability make them an ideal choice for creating safe and stable temporary bridges or walkways.

- Q:What are the common maintenance practices for steel props?

- Common maintenance practices for steel props include regular cleaning and inspection to remove dirt, rust, and any other contaminants. It is important to lubricate the moving parts to prevent friction and ensure smooth operation. Regular checks should be conducted to identify any damage or wear and tear, and repairs or replacements should be made promptly. Additionally, storing the props in a dry and well-ventilated area helps to prevent corrosion and prolong their lifespan.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Adjustable Steel Prop - Vertical Structure Support System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords