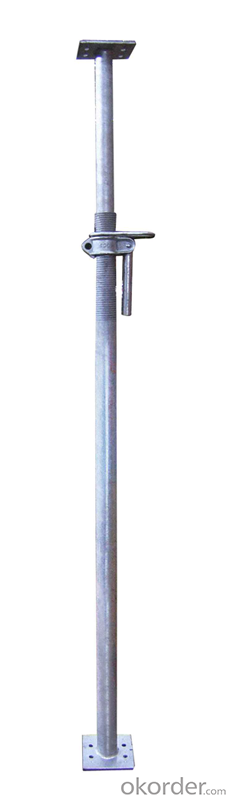

Heavy Duty Steel Prop of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Props:

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q: Are steel props commonly used in power plant construction projects?

- Yes, steel props are commonly used in power plant construction projects. They provide essential support and stability during the construction process, especially when heavy equipment and structures are being installed.

- Q: What are the main considerations when using steel props for supporting false ceilings?

- When utilizing steel props to support false ceilings, there are several key factors to take into account. To begin with, it is vital to ensure that the steel props are sized and strengthened appropriately to bear the weight of the false ceiling. The weight of the false ceiling will vary depending on factors such as the materials utilized and the size of the area it covers. It is crucial to select steel props with a load-bearing capacity that surpasses the weight of the false ceiling in order to guarantee stability and safety. Next, the height and spacing of the steel props must be carefully calculated and planned. The spacing between the steel props will depend on the size and weight of the false ceiling, as well as any additional loads that may be placed on it, such as lighting fixtures or ventilation systems. It is important to ensure that the spacing of the steel props is sufficient to evenly distribute the weight of the false ceiling and any additional loads. Another consideration is the installation process of the steel props. It is vital to adhere to the manufacturer's instructions and guidelines for proper installation. The steel props should be securely anchored to both the floor and the ceiling to prevent any movement or instability. Additionally, regular inspections of the steel props should be conducted to ensure they remain in good condition and are not damaged or weakened over time. Furthermore, fire safety is a crucial consideration when using steel props to support false ceilings. While steel is a fire-resistant material, it is important to ensure that the false ceiling materials and any insulation used are also fire-resistant. Adequate fire protection measures should be in place to prevent the spread of fire in case of an emergency. Lastly, it is important to take into account any building regulations or codes that may pertain to the installation of steel props for false ceilings. Local building codes may have specific requirements regarding the use of steel props, such as minimum load-bearing capacities or installation methods. It is essential to comply with these regulations to ensure that the installation is safe and meets the necessary standards. Overall, the main considerations when utilizing steel props for supporting false ceilings include selecting appropriate prop size and strength, calculating height and spacing, proper installation, fire safety measures, and compliance with building regulations. By carefully considering these factors, one can ensure the safe and effective use of steel props for supporting false ceilings.

- Q: Can steel props be used in the construction of temporary access ramps?

- Yes, steel props can be used in the construction of temporary access ramps. Steel props are commonly used in construction to provide temporary support and stability to structures. They are adjustable and can be set to the desired height, making them ideal for creating ramps with the necessary incline for accessibility. Steel props are strong and durable, capable of withstanding heavy loads, which is essential for ensuring the safety of individuals using the ramp. Additionally, their versatility allows for easy installation and dismantling, making them suitable for temporary construction projects such as access ramps. Overall, steel props are a reliable choice for constructing temporary access ramps due to their strength, adjustability, and ease of use.

- Q: What are the advantages of using steel props over other support systems?

- There are several advantages of using steel props over other support systems. Firstly, steel props are known for their strength and durability. They are made from high-quality steel, which provides excellent load-bearing capacity and can withstand heavy loads. This makes them ideal for supporting structures during construction or renovation projects. Secondly, steel props offer a high level of adjustability. They are designed with telescopic tubes that can be easily extended or retracted to the desired height. This adjustability feature allows for precise positioning and ensures a perfect fit for various applications, making them versatile and adaptable to different construction scenarios. Another advantage of steel props is their stability. The steel tubes are designed to provide a secure and stable base, ensuring that the supported structure remains steady and safe. This stability is especially crucial when working on tall or complex structures, as it minimizes the risk of accidents or structural failures. Additionally, steel props are relatively lightweight and easy to handle. They can be quickly assembled and disassembled, making them convenient for transportation and reducing labor costs. This ease of use and portability make steel props a practical option for projects that require frequent repositioning or adjustments. Furthermore, steel props are cost-effective. Compared to other support systems, they offer a more affordable solution without compromising on quality or performance. Their long lifespan and resistance to wear and tear also contribute to their cost-effectiveness, as they require minimal maintenance or replacement over time. Lastly, steel props are environmentally friendly. They can be recycled and reused, reducing waste and minimizing the environmental impact of construction projects. This sustainability aspect makes steel props a desirable choice for companies and industries aiming to adopt more eco-friendly practices. In conclusion, the advantages of using steel props over other support systems include their strength, adjustability, stability, ease of use, cost-effectiveness, and environmental friendliness. These qualities make steel props a reliable and versatile choice for various construction applications.

- Q: What are the maximum allowable deflections for steel props?

- The maximum allowable deflections for steel props depend on various factors such as the specific design code and the type of steel prop being used. However, in general, the maximum allowable deflections for steel props are typically limited to a fraction of the length of the prop, usually ranging from 1/200 to 1/400 of the unsupported length. This ensures structural stability and safety during temporary support applications. It is crucial to consult the relevant design guidelines or manufacturer specifications to determine the exact maximum allowable deflections for a specific steel prop.

- Q: How do you ensure proper load transfer when using steel props on soft or weak soils?

- To ensure proper load transfer when using steel props on soft or weak soils, there are several measures that can be taken: 1. Soil investigation: Conduct a thorough soil investigation to determine the properties and characteristics of the soil. This includes identifying its strength, compressibility, and load-bearing capacity. This information will help in determining the appropriate load-bearing capacity of the steel props. 2. Proper prop selection: Select steel props with adequate load-bearing capacity that can effectively distribute the load to the weak or soft soil. This requires considering the maximum expected load, the depth of the soil, and the specific conditions of the site. 3. Spacing and positioning: Determine the correct spacing and positioning of the steel props to ensure even load distribution. This may involve using additional props or increasing their density in areas with weaker soils. 4. Base support: Provide sufficient support at the base of the props to prevent sinking or tilting. This can be achieved by using steel plates or timber boards to spread the load over a larger area and reduce the pressure on the weak soil. 5. Ground improvement techniques: Depending on the severity of the soil's weakness, ground improvement techniques may be required to enhance load transfer. These techniques can include soil stabilization methods such as compaction, grouting, or the use of geosynthetic materials. 6. Monitoring: Regularly monitor the performance of the steel props during construction to ensure they are effectively transferring the load. This can involve measuring the settlement, deflection, or any signs of instability, and taking appropriate remedial actions if necessary. It is important to note that the above measures serve as general guidelines, and the specific approach should be tailored to the individual site conditions and project requirements. Consulting with an experienced geotechnical engineer or structural engineer is recommended to ensure proper load transfer and overall stability of the structure.

- Q: Do steel props require any special inspections or certifications?

- Special inspections and certifications are typically necessary for steel props. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to provide temporary support or to support temporary structures during construction or renovation projects. These props are designed to withstand heavy loads and must meet specific safety standards to ensure their structural integrity. In most jurisdictions, qualified professionals must regularly inspect steel props to ensure they are in good working condition and meet safety requirements. These inspections may involve visual checks for damage or wear, as well as load testing to determine the props' load-carrying capacity. Furthermore, steel props may need certification from regulatory bodies or industry standards organizations. These certifications guarantee that the props have undergone thorough testing and meet specific safety criteria. The certification process typically includes rigorous evaluations of the props' design, materials, and performance. Contractors, construction companies, and individuals using steel props must comply with these inspection and certification requirements. Regular inspections and proper certification are crucial for worker safety, accident prevention, and the structural stability of temporary structures or support systems. Moreover, it is advisable to adhere to the manufacturer's guidelines and instructions for the appropriate use, maintenance, and storage of steel props. This helps extend their lifespan, maintain their performance, and minimize the risk of failure or accidents. In conclusion, while steel props offer a dependable and versatile solution for temporary support in construction projects, they necessitate special inspections and certifications to ensure safety and compliance with regulatory standards.

- Q: Are steel props suitable for supporting temporary agricultural structures?

- Yes, steel props are suitable for supporting temporary agricultural structures. Steel is a durable and strong material that can withstand the weight and pressure exerted by agricultural structures such as greenhouses, shade structures, or crop protection systems. Additionally, steel props offer stability and can be easily adjusted or customized to fit different sizes and heights of agricultural structures.

- Q: How do steel props accommodate for changes in load during construction?

- Steel props are adjustable and versatile support systems that are commonly used in construction projects to provide temporary support to structures. They are designed to accommodate for changes in load during construction by allowing for easy adjustment of their height and load-bearing capacity. One way steel props accommodate for changes in load is through their telescopic design. These props consist of an inner tube, which can be extended or retracted, and an outer tube that provides additional support. By simply adjusting the height of the inner tube, the steel prop can be easily modified to support different loads or to compensate for changes in the structure's weight distribution. Furthermore, steel props often come with adjustable load-bearing heads. These heads can be rotated or tilted to ensure that the load is evenly distributed and properly supported. By manipulating the position and orientation of the load-bearing head, contractors can effectively distribute the weight, preventing any overload on a particular area and ensuring the stability of the structure. In addition, steel props are typically rated for specific load capacities and are engineered to withstand various loads. This means that they can be selected based on the anticipated load requirements of the construction project. If the load changes during construction, props with higher load capacities can be easily substituted to ensure the structure remains adequately supported. Overall, steel props offer flexibility and adaptability to accommodate for changes in load during construction. Through their telescopic design, adjustable load-bearing heads, and available load capacities, they provide a reliable and efficient solution for supporting structures under varying load conditions.

- Q: Steel support can stay in the wall joint position, if not, then why?

- Note: the I-beam is and even steel cage wall welded together, lifting and reinforcement cage is synchronous lifting installation, when pouring concrete, concrete and steel reinforcement cage are I-beam wrapped inside, while under load

Send your message to us

Heavy Duty Steel Prop of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords