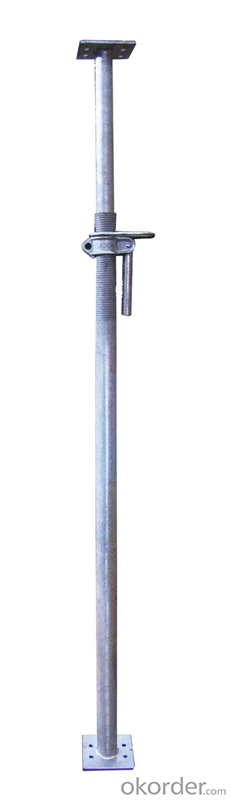

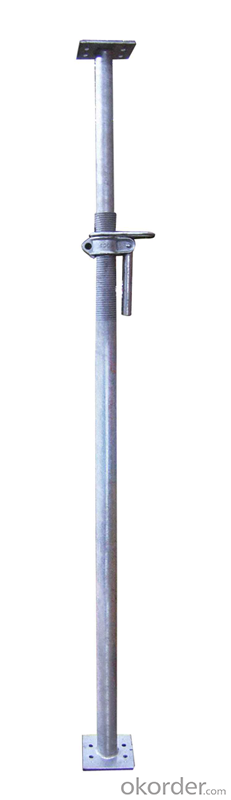

Formwork Steel Props Scaffolding for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product information:

Model Number: GTJ-P003

Name: Q235 High Quality Steel Slab Props

Material: Q235

Thickness: 1.6mm to3mm or as your requirements

Surface Treatment: as per requirements

Standard: use your standard or international standard

Dimension: Light duty 40-48mm, MID Duty 48-56/58mm, Heavy duty 48-60mm

Characteristics:

1. Reliable performance

2. Corrosion resistance

3. Durable finish standards

Functions

It is used for construction supporting, timber, formwork, concrete slab and so on. It is very easy and reliable to use

Why Choose Us

1. We are experienced manufacturer in Hebei with more than 4 years experience and cooperating with more many countries.

2. We supply qualified products which are certified by SGS and ISO9001:2008. Strict QC to make sure your profit.

3. Timely delivery can be guaranteed because we have a factory which covers an area of 30000sqm and its daily output is more than 50 tons.

4. A competitive price can be offered because we are a professional manufacturer of scaffolding with an advantage on cost-controlling & production management.

- Q: Can steel props be used in supporting temporary sound systems?

- Indeed, temporary sound systems can be supported by steel props. In construction endeavors, steel props are frequently employed to offer provisional support to structures. With their height adjustability and ability to withstand substantial loads, steel props are well-suited for providing stability to sound systems, which can be weighty and necessitate reliable support. The simplicity of setting up and dismantling steel props enhances their convenience for temporary installations. Moreover, their robustness and steadiness guarantee the security and stability of the sound system during use. Nevertheless, it is crucial to ensure the appropriate installation and positioning of steel props to optimize support and avoid any mishaps or damages.

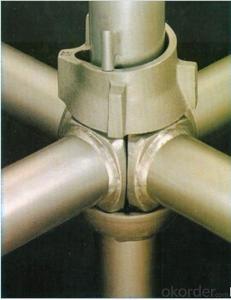

- Q: Can steel props be used for supporting scaffolding systems?

- Yes, steel props can be used for supporting scaffolding systems. Steel props are commonly used as vertical supports in construction projects and can provide stability and strength to scaffolding structures. They are adjustable in height, making them suitable for various types of scaffolding systems.

- Q: Big steel pipe support painted what color look good

- Dark, bright red color orange smilax. Use it to design a bright, warm, vibrant and land color.

- Q: What are the common maintenance practices for steel props?

- Common maintenance practices for steel props include regular cleaning and inspection to remove dirt, rust, and any other contaminants. It is important to lubricate the moving parts to prevent friction and ensure smooth operation. Regular checks should be conducted to identify any damage or wear and tear, and repairs or replacements should be made promptly. Additionally, storing the props in a dry and well-ventilated area helps to prevent corrosion and prolong their lifespan.

- Q: Can steel props be used in the construction of prefabricated buildings?

- Steel props, which are also referred to as steel supports or scaffolding props, have the capability to be utilized in the construction of prefabricated buildings. In the realm of construction, steel props are commonly employed to provide temporary support to structures throughout building and renovation projects. Prefabricated buildings are fabricated using pre-engineered components that are manufactured away from the construction site and subsequently transported for assembly. During the assembly procedure, steel props can be employed to offer support to the prefabricated components, thus guaranteeing stability and structural integrity. With adjustable height and easy installation and removal, steel props are well-suited for utilization in the construction of prefabricated buildings.

- Q: What are the common safety training requirements for using steel props?

- The utilization of steel props necessitates adherence to several safety training requirements. These include: 1. Proper handling techniques: Training sessions should encompass safe lifting, carrying, and transporting of steel props to prevent strain and injury. This involves understanding weight limitations and utilizing appropriate lifting equipment when necessary. 2. Inspection and maintenance: Workers should receive training on inspecting steel props for signs of damage or deterioration before use. This entails checking for cracks, bends, rust, or any other defects that may compromise the structural integrity of the props. 3. Assembly and disassembly procedures: Proper training should be provided on correctly assembling and disassembling steel props. This entails understanding the correct sequence of components and ensuring secure connections. 4. Load capacity and weight distribution: Workers need to be educated on the maximum load capacity of steel props and how to evenly distribute weight to prevent overloading or instability. This knowledge is crucial for maintaining a safe working environment. 5. Stability and bracing: Training should emphasize the importance of providing adequate stability and bracing for steel props. Workers must understand how to properly secure props to prevent accidental collapse or movement during use. 6. Personal protective equipment (PPE): Safety training should include the requirement of wearing appropriate PPE, such as hard hats, safety goggles, gloves, and steel-toed boots, when working with steel props. 7. Emergency procedures: Workers should be trained on the appropriate emergency procedures in the event of accidents or incidents involving steel props. This includes knowing how to safely evacuate the area and administer basic first aid if necessary. In summary, safety training for the use of steel props should prioritize raising awareness, teaching proper handling techniques, and ensuring compliance with safety guidelines. This will help minimize the risk of accidents and injuries in the workplace.

- Q: Are steel props resistant to corrosion and rust?

- Yes, steel props are generally resistant to corrosion and rust. Steel is an alloy composed primarily of iron and carbon, and it is known for its strength and durability. However, steel can still corrode and rust under certain conditions, such as exposure to moisture, chemicals, or extreme temperatures. To enhance the corrosion resistance of steel props, they are often treated with protective coatings or galvanized. These coatings act as a barrier, preventing water and oxygen from reaching the steel surface and causing corrosion. Regular maintenance and inspection are also important to ensure the continued resistance to corrosion and rust.

- Q: How do steel props contribute to the safety of workers on construction sites?

- Steel props contribute to the safety of workers on construction sites by providing temporary support to structures, ensuring stability and preventing collapse. These props are adjustable and can withstand heavy loads, which enhances the safety of workers by preventing accidents caused by structural failure or falling debris. Additionally, steel props offer flexibility in terms of height adjustment, allowing workers to work at different levels comfortably and securely. Overall, steel props play a crucial role in maintaining a safe working environment on construction sites.

- Q: Can steel props be used for supporting prefabricated structures?

- Indeed, prefabricated structures can be supported using steel props. These adjustable and robust support systems are capable of offering either temporary or permanent support to a variety of structures, including prefabricated ones. Typically constructed from top-notch steel, these props are engineered to possess the necessary strength to uphold the weight of the structure they support. During the construction or installation of prefabricated structures, these props can be effortlessly adjusted and firmly secured in place to provide the required support. Consequently, steel props find extensive use in the construction sector, where they serve a multitude of purposes, including the support of prefabricated structures.

- Q: Are steel props suitable for supporting heavy loads on construction sites?

- Yes, steel props are suitable for supporting heavy loads on construction sites. Steel props are known for their strength and durability, making them ideal for providing reliable support for heavy loads during construction activities.

Send your message to us

Formwork Steel Props Scaffolding for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords