High Strength PET Woven Geotextile White Color WOVEN GEOTEXTILE/HIGH STRENGTH

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PET High Strength Woven Geotextile

PET High-strength Woven Geotextile is a type of high-strength woven fabric used in geotechnical engineering applications.

It is made of polyester (PET) fibers that are woven together to form a strong and durable material that can withstand heavy loads and resist deformation.

This geotextile is commonly used in soil stabilization, erosion control, drainage systems, and road construction.

Its high tensile strength, excellent durability, and resistance to chemical and biological degradation make it an ideal material for use in harsh environmental conditions.

PET High-strength Woven Geotextile is available in a range of sizes, strengths, and specifications to meet the specific needs of various construction projects.

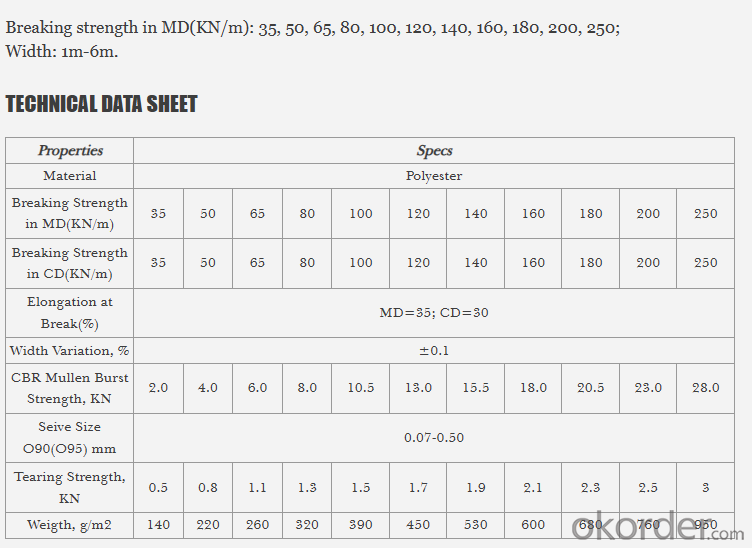

Specification:

FEATURES:

1. High strength, low deformation

2. Durability: steady property, not easy to resolved, air slaked and can keep the original property long term

3. Anti-erosion: anti-acid, anti-alkali, resists insects and mould

4. Permeavility: could control the sieve size to retain certain permeability

PRODUCTION:

Weaving: The PET fibers are woven together on a loom to create the geotextile fabric.

The weaving process can be done using various techniques, such as plain weave, twill weave, and satin weave, to create different patterns and strengths in the fabric.

APPLICATION:

1. It is widely used in river, coast, harbor, highway, railway, wharf, tunnel, bridge and other geotechnical engineering.

2. It could meet all kinds of geotechnical projects needs such as filtration, separation, reinforcement, protection and so on

- Q: How do geotextiles contribute to soil remediation?

- Geotextiles contribute to soil remediation by acting as a barrier or filter to control erosion, retain sediment, and stabilize the soil. They help to prevent the spread of contaminants, regulate water flow, and enhance the effectiveness of other remediation techniques such as soil vapor extraction or bioremediation.

- Q: Can geotextiles be used for reinforcement in asphalt overlays?

- Yes, geotextiles can be used for reinforcement in asphalt overlays. Geotextiles are commonly used to improve the performance and longevity of asphalt overlays by providing reinforcement and mitigating cracking. They help distribute the load and stresses, reduce reflective cracking, and improve the overall structural integrity of the pavement.

- Q: What are the different geotextile filter criteria?

- The different geotextile filter criteria include permeability, retention, durability, and compatibility with the surrounding soil or materials.

- Q: Are geotextiles resistant to UV radiation?

- Yes, geotextiles are generally resistant to UV radiation.

- Q: Can geotextiles be used in agricultural waste management systems?

- Yes, geotextiles can be used in agricultural waste management systems. Geotextiles are commonly used to control erosion, improve drainage, and provide filtration in various applications. In agricultural waste management, they can be utilized to line storage ponds, control the flow of water, and separate different layers of waste materials. Additionally, geotextiles can help in preventing nutrient leaching and protecting the surrounding environment from contamination.

- Q: Construction Method of Sand and Gravel Cushion on Slope Soil Geotextile

- Online to find some relevant construction methods, Google library on a lot. After downloading, modify, targeted to add that is the slope of geotextile sand and gravel cushion construction method.

- Q: Geotextile back to the pebble and geotextile bag what inspection batch

- I professional production geomembrane geotextile and other materials, wish smooth

- Q: Unit of the quality of 400 geotextile piercing strong is generally how much? Hurry more

- First, geotextile polyester staple fiber geotextile (PET) and polyester filament geotextile two. Two kinds of geotextile anti-puncture strong (should be CBR burst strong) different. Polyester staple geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester staple geotextile CBR burst strength ≥ 2.1KN. Polyester filament geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester filament geotextile CBR burst strength ≥ 39KN. 400g GB polyester staple geotextile longitudinal and horizontal tear strength ≥ 0.33KN, 400g GB polyester filament geotextile longitudinal and horizontal tear strength ≥ 0.56KN.

- Q: Geotextile filter layer set which quota

- Filter cloth, monofilament filter cloth, polypropylene filter cloth, nylon green monofilament

- Q: How do geotextiles enhance drainage systems?

- Geotextiles enhance drainage systems by providing filtration and separation of soil layers, preventing clogging and promoting water flow through the system.

Send your message to us

High Strength PET Woven Geotextile White Color WOVEN GEOTEXTILE/HIGH STRENGTH

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords