Non Woven Coir Geotextiles - Continuous Filament PET Woven Geotextile High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PET Woven Geotextile

PET Woven Geotextile Introduction

Woven Geotextile is made of high tenacity and high molecular weight polyester yarns. Wear-resisting, bursting resistant and high tensile strength, also provide different strength at low elongation.

PET Woven Geotextile Application

Woven geotextile can be applied in soil stabilization, embankment, reinforced wall and slope, sidewalk paver, coastal and riverbank revetments, landfill separators and capping, etc.

PET Woven Geotextile Advantage

-High tensile strength

-Wear resistant

-Burst resistant

-Easy carry and easy application

PET Woven Geotextile Specifications

Tensile strength(kN/m) | 100/50 | 200/50 | 400/50 | 600/50 | 800/50 | 1000/50 | 60/60 | 100/100 | 120/120 | 200/200 | 220/220 |

MD Values | 100 | 200 | 400 | 600 | 800 | 1000 | 60 | 100 | 120 | 200 | 220 |

CMD Values | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 100 | 120 | 200 | 220 |

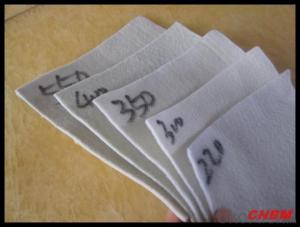

PET Woven Geotextile photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Is there a geotextile between the waterproofing membrane and the rigid layer?

- Need to prevent the waterproof layer from being pierced. Huazhi geotextile material manufacturers

- Q: Geotextile in the asphalt layer under what role

- Waterproof, isolated

- Q: What are the different types of geotextile installation equipment?

- Some different types of geotextile installation equipment include geotextile rollers, geotextile spreaders, geotextile stitchers, and geotextile tensioners. These tools are used to properly position, secure, and connect geotextiles during installation for various applications such as erosion control, drainage, and reinforcement.

- Q: Are geotextiles recyclable?

- Yes, geotextiles are recyclable. They can be reused or repurposed for various applications, reducing waste and promoting sustainability. However, the recyclability may vary depending on the specific type and composition of the geotextile.

- Q: Geotextile seepage seams how to deal with

- Quick drying cement

- Q: Geotextile effect

- First, the drainage effect: polyester staple acupuncture geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. Second, the role of contraction: When the water from the fine soil into the coarse soil layer, the use of polyester staple acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand , Small stone, etc., in order to maintain the stability of soil and water engineering. Third, the isolation role: the use of polyester staple acupuncture geotextile with different physical properties of the building materials to isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Fourth, the role of puncture: and geomembrane combined into a composite waterproof impermeable material, play the role of anti-puncture. High tensile strength, good permeability, breathable properties, high temperature resistance, anti-freeze, anti-aging, corrosion-resistant, not moth-eaten. Polyester staple acupuncture geotextile is a widely used geosynthetics.

- Q: What are the advantages of using geotextiles over traditional construction materials?

- There are several advantages of using geotextiles over traditional construction materials. Firstly, geotextiles are lightweight and flexible, making them easier to handle and install compared to heavier materials like rocks or concrete. This results in reduced labor and transportation costs. Secondly, geotextiles offer excellent filtration and drainage properties, allowing water to pass through while preventing the migration of fine particles. This helps in stabilizing the soil and preventing erosion, which is particularly beneficial in areas prone to heavy rainfall or water runoff. Additionally, geotextiles provide increased strength and reinforcement to the soil, enhancing overall stability and load-bearing capacity. This is especially useful in areas with weak or unstable soils, where traditional materials may not provide adequate support. Furthermore, geotextiles are resistant to biological degradation, chemicals, and UV radiation, ensuring long-term durability and reducing the need for frequent maintenance or replacement. Overall, the use of geotextiles in construction offers cost-effective, sustainable, and versatile solutions for various soil-related challenges, providing numerous advantages over traditional construction materials.

- Q: Water stable health with the geotextile, sticky on the water stable, how quickly cleared

- I professional production geomembrane / geotextile, the highest cost, I wish smooth

- Q: How do geotextiles improve the performance of embankments?

- Geotextiles improve the performance of embankments by providing reinforcement and stability to the soil structure. They act as a barrier against soil erosion, preventing the loss of soil particles and maintaining the integrity of the embankment. Geotextiles also allow water to pass through while retaining the soil, enhancing drainage and preventing water buildup that could weaken the embankment. Additionally, geotextiles distribute the load more evenly, reducing the potential for settling and improving overall stability of the embankment.

- Q: Waterproof and protective layer between which type of geotextile isolation layer

- Personally think to take impervious geotextile. Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Check the original post & gt; & gt; trouble to adopt, thank you!

Send your message to us

Non Woven Coir Geotextiles - Continuous Filament PET Woven Geotextile High Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords